Clamping and moving device of winding type cable terminal crimping equipment

A technology of mobile device and terminal assembly device, which is applied in the direction of connection, line/collector parts, electrical components, etc. through deformation, and can solve the problems of difficult removal of coiled cables and misalignment of positions, etc. Achieve the effects of reducing size, preventing cable sagging, and improving the quality of tinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

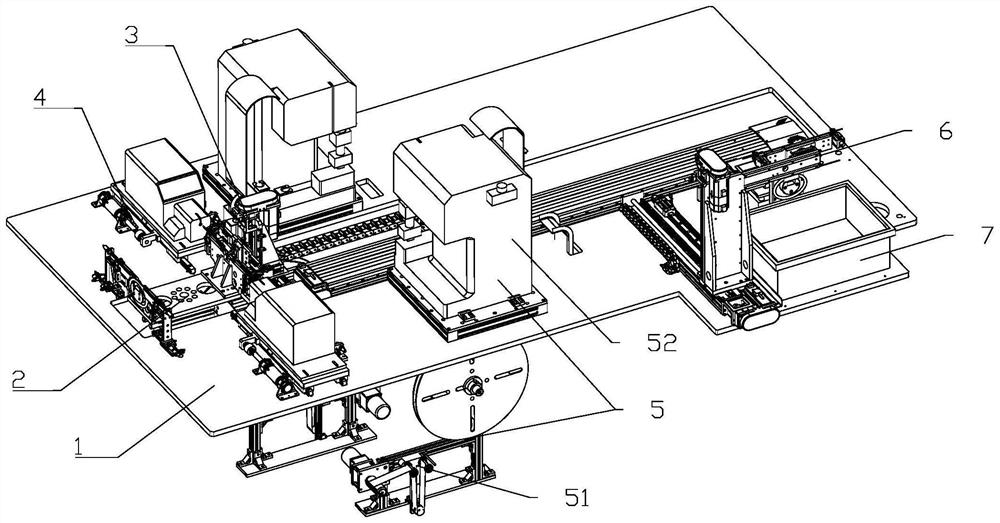

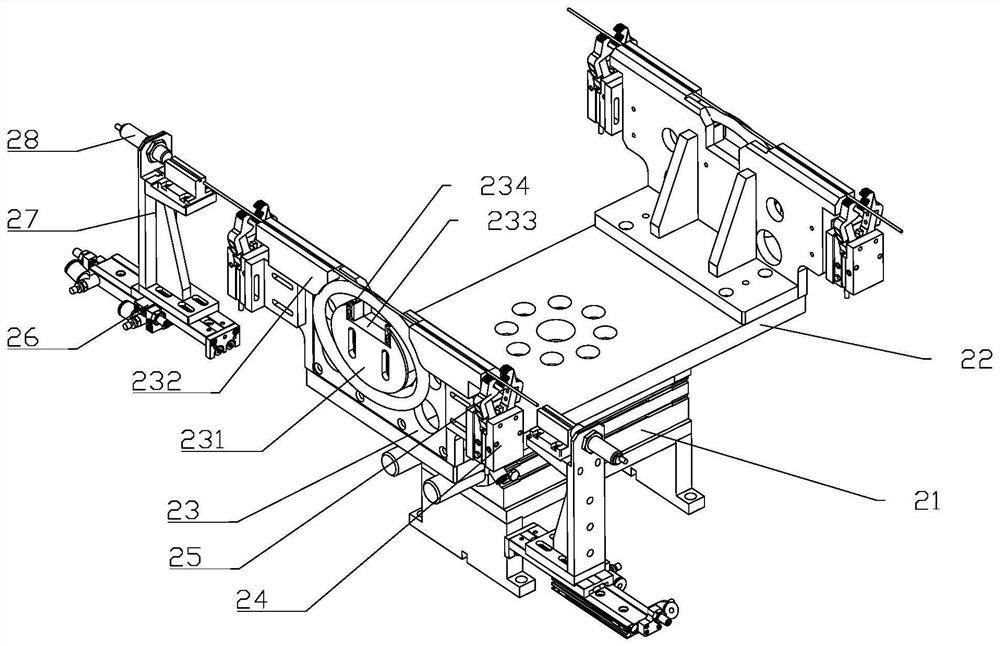

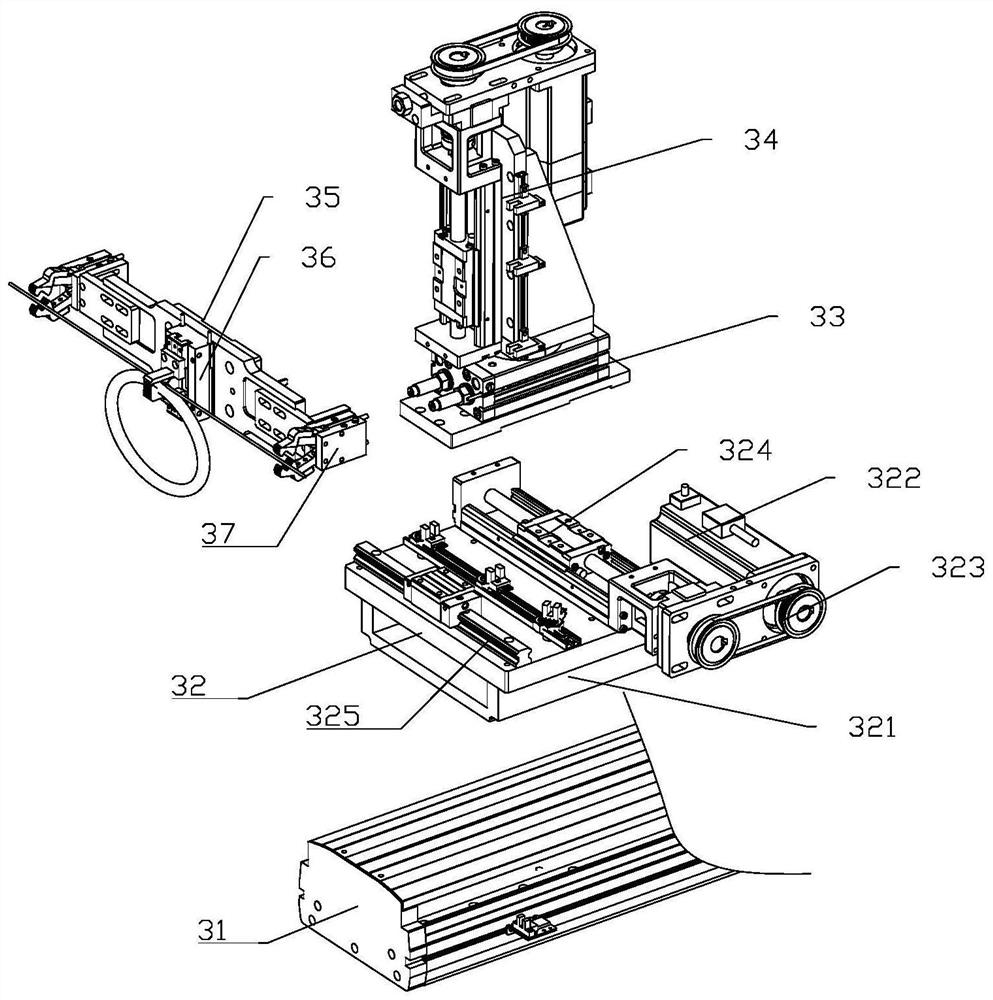

[0021] like Figure 1-Figure 4 As shown, a coiled cable terminal equipment includes a frame 1 and a loading and positioning device 2 installed on the frame 1, a clamping and moving device 3, a stripping device 4, a terminal assembly device 5 and a tinned bottom Material device 6; the clamping mobile device 3 is connected with the feeding positioning device 2, and the clamping mobile device 3 corresponds to three stations, which are the stripping and retrieving station 301, the terminal printing station 302 and the unloading station 303 The stripping device 4 and the terminal assembly device 5 are provided with two groups, and along the processing direction, the stripping device 4 and the terminal assembly device 5 are sequentially arranged on both sides of the clamping mobile device 3; the feeding positioning device 2 The wire stripping device 4 corresponds to the stripping and retrieving station 301, the terminal assembly device 5 corresponds to the terminal punching station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com