Motor rotor supporting bearing lubrication waste grease discharge structure capable of overcoming assembly errors

A technology of motor rotor and support bearing, applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem of excessive annular gap, affecting the normal operation of the bearing, etc., to prolong the service life and avoid excessive loss. , to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

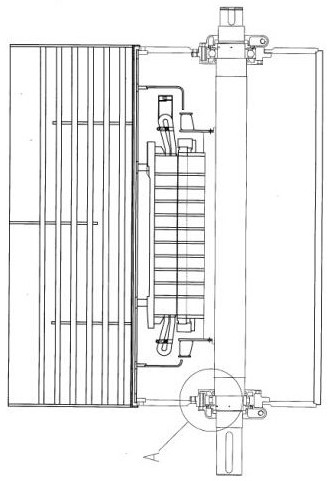

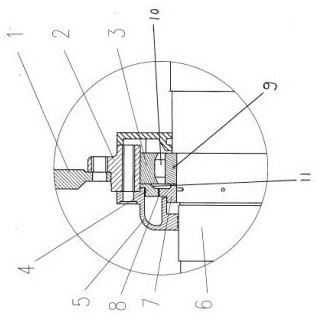

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

[0018] A motor rotor support bearing lubricating waste grease discharge structure capable of overcoming assembly errors, comprising a motor drive end cover 1 and a motor shaft 6, a motor rotor support bearing bearing seat 2 is arranged on the center hole of the motor drive end cover 1, A motor rotor support bearing is arranged in the motor rotor support bearing housing 2, a motor shaft 6 is arranged in the motor rotor support bearing, and the bearing outer ring 3 of the motor rotor support bearing is fixedly arranged in the motor rotor support bearing housing 2. The bearing inner ring 9 of the rotor support bearing is shrunk on the motor shaft 6, a roller 10 is arranged between the bearing inner ring 9 and the bearing outer ring 3, and the motor shaft 6 outside the bearing inner ring 9 is shrunk with oil Ring 7, a bearing outer cover 5 is arranged on the outer surface of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com