Turbulence type embedded compensation dropper

A turbulent flow and dripper technology, applied in the field of agricultural water-saving irrigation, can solve problems that affect the growth or death of crops, uneven water output from drippers, and affect compensation effects, etc., achieve good anti-siphon function, prevent clogging, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

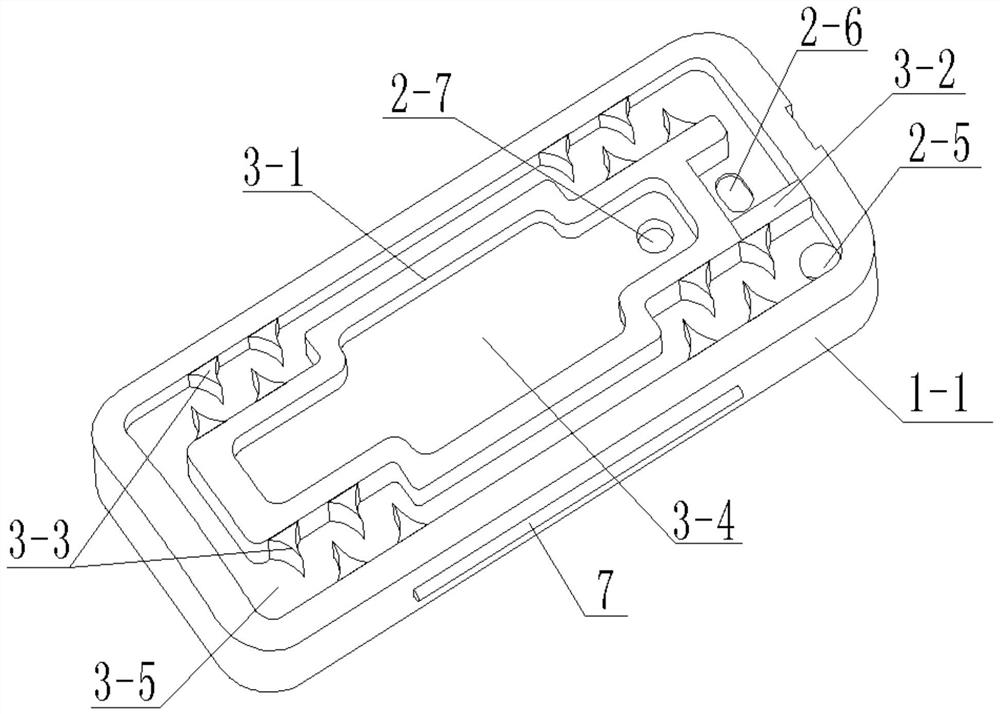

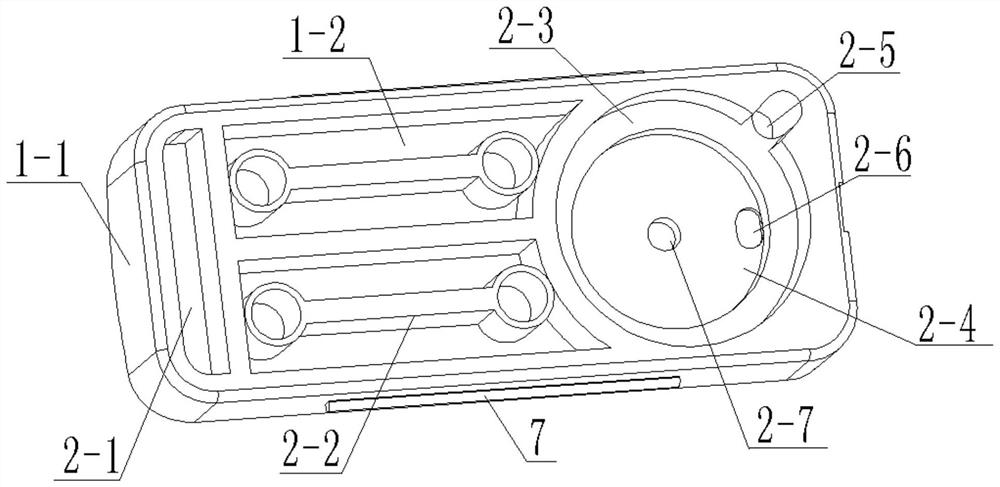

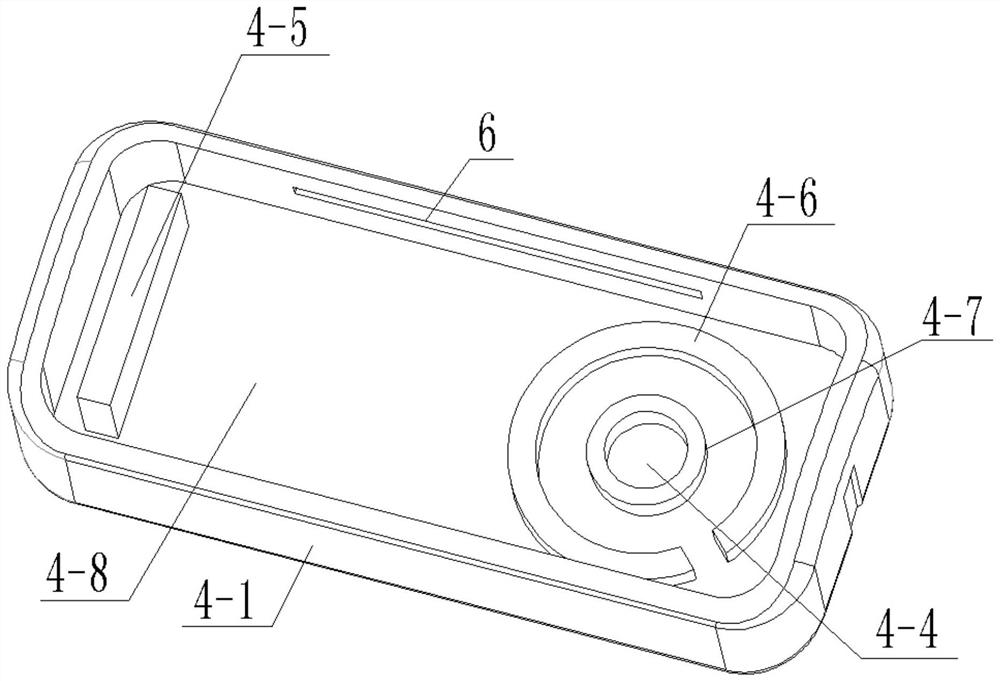

[0019] see figure 1 , 2 , 3, 4 and Figure 5 , the present invention includes a fluid part, a bottom case part and a compensating film 5 arranged between the fluid part and the bottom case part; Insert the square ring 1-1 of the fluid part into the recessed cavity 4-8 of the bottom shell part, and the outer wall of the square ring 1-1 and the inner wall of the recessed cavity 4-8 are closely attached; in order to avoid the fluid part from being inserted to the bottom When the shell part is up, the direction is wrong, and there are also positioning slots 2-1 and positioning columns 4-5. Only when the positioning slots 2-1 and positioning columns 4-5 are connected correctly can the square ring 1-1 be inserted into the concave cavity 4-8, otherwise it cannot be assembled successfully, ensuring the accuracy of the assembly; the fluid part includes a fluid shell, a water inlet part and a water outlet part; the water inlet part and the water outlet part are both arranged on the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com