A three-phase continuous flow induction heating green sterilization system and method

A flow induction heat, three-phase technology, applied in heating, application, disinfection and other directions, can solve the problems of inability to further realize induction sterilization of liquid food, inability to obtain high-density induction current, etc., to avoid local overheating of raw materials and induction of electric field strength. The effect of boosting and increasing the induced current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

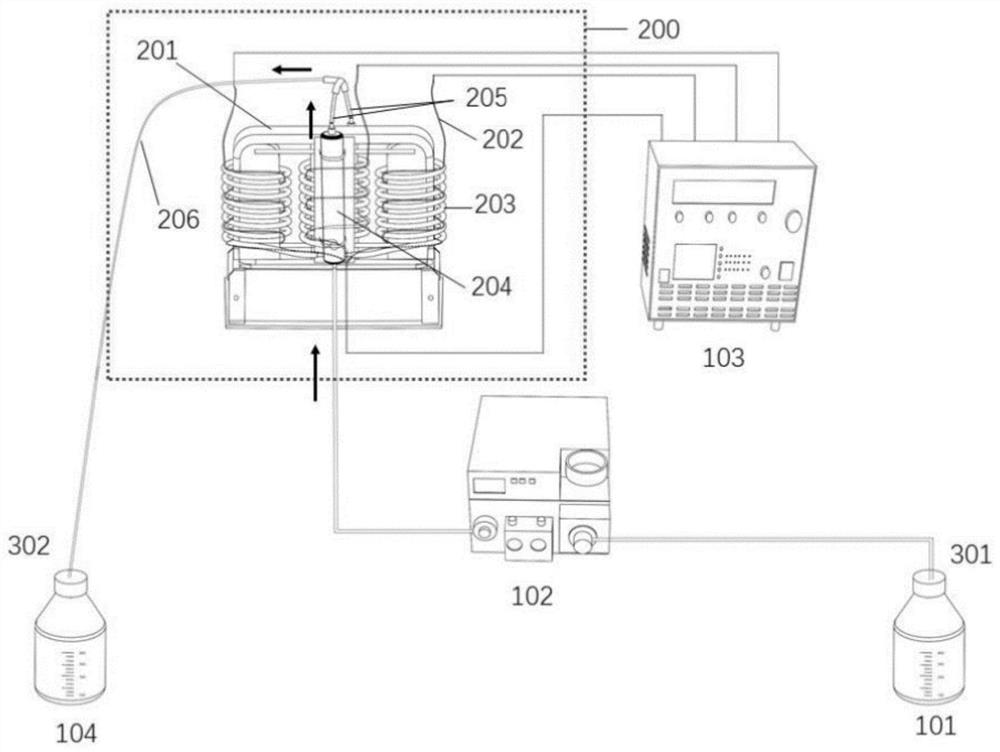

[0031] This embodiment provides a three-phase continuous flow induction heat green sterilization system I, see figure 1 , including the sampling tank 101, the pump 102, the three-phase power supply 103, the sampling tank 104 and the sterilization treatment equipment 200.

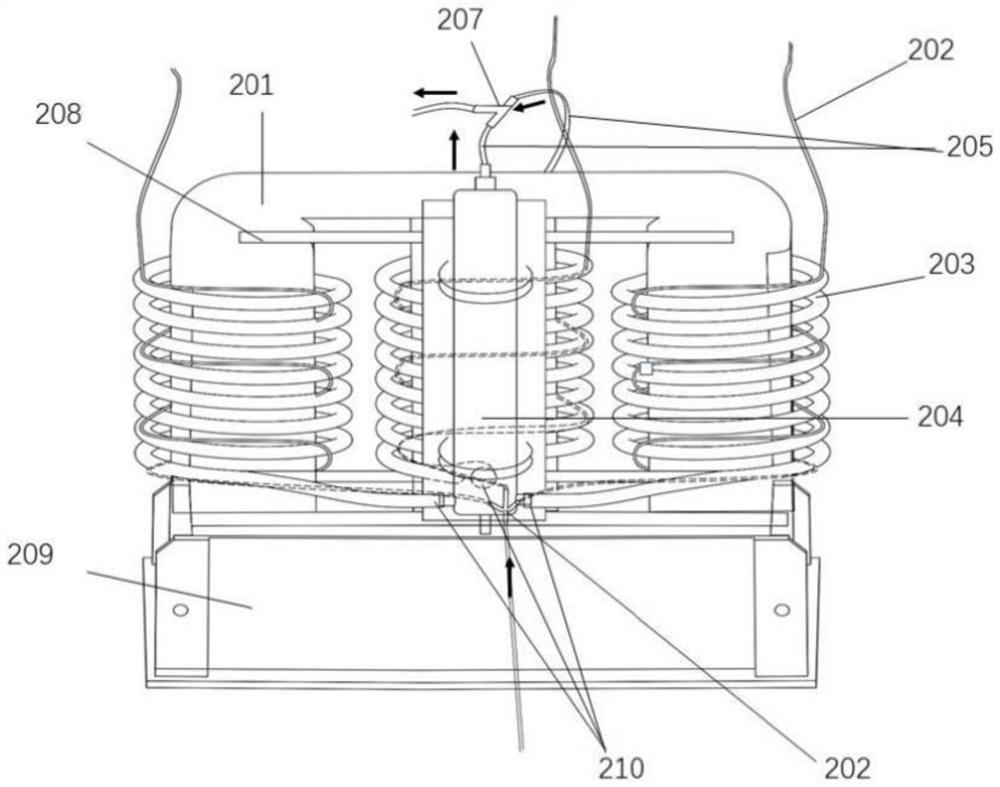

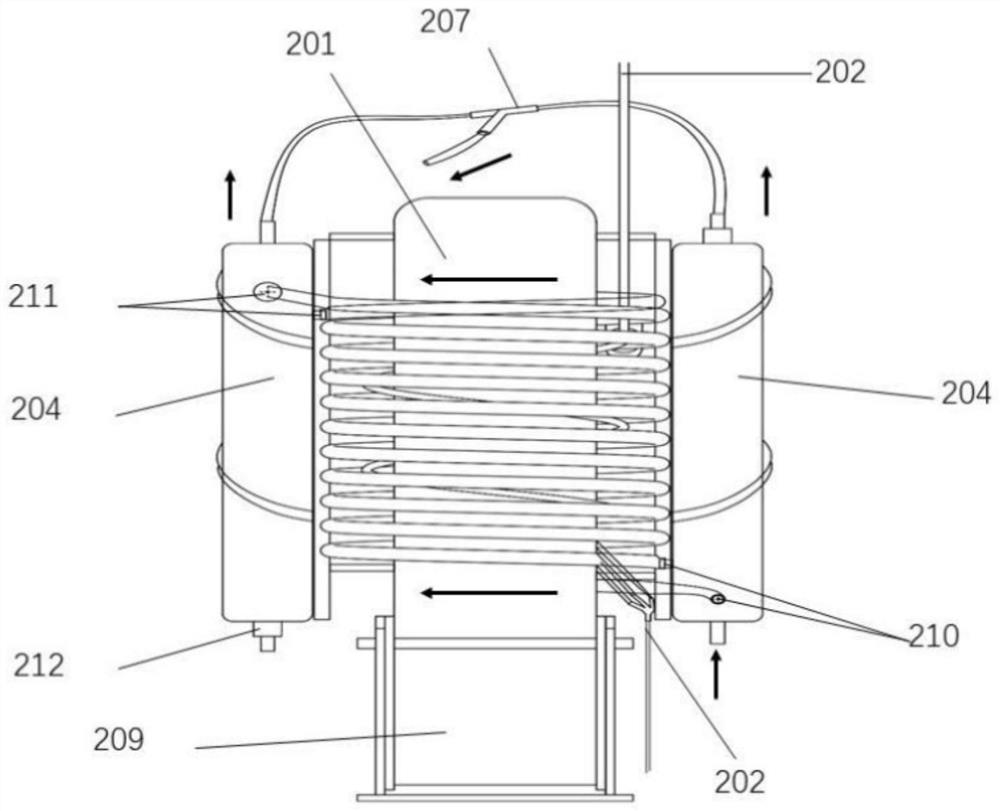

[0032] like Figure 2-Figure 4 As shown, the sterilization treatment equipment 200 includes: a three-column magnetic circuit 201, an excitation coil 202, a magnetic coupling tube 203, a material storage tube 204, a processing chamber 205, a liquid outlet tube 206, a three-way connector 207, a fixed plate 208 and Pedestal 209.

[0033] like figure 2 As shown, in the sterilization treatment equipment 200 , the excitation coil 202 and the magnetic coupling tube 203 are both wound around the three-column magnetic circuit 201 . The excitation coil 202 is connected to the three-phase power supply 103 .

[0034] Depend on image 3 side view shown and Figure 4As can be seen from the top view shown, the steri...

Embodiment 2

[0053] This embodiment provides a sterilization method using the three-phase continuous flow induction heat green sterilization system given in the first embodiment, and the material liquid takes the kiwi juice filtered by four layers of gauze as an example.

[0054] Specifically, as figure 1 As shown, the adopted three-phase continuous flow induction thermal green sterilization system includes: a sampling tank 101 , a pump 102 , a three-phase power supply 103 , a sampling tank 104 and a sterilization treatment device 200 . The sterilization treatment equipment 200 includes: a three-column magnetic circuit 201 , an excitation coil 202 , a magnetic coupling tube 203 , a material storage tube 204 , a processing chamber 205 , a liquid outlet tube 206 , a three-way connector 207 , a fixing plate 208 and a base 209 .

[0055] The three-pillar magnetic circuit 201 is made of amorphous nanocrystalline soft magnetic material.

[0056] In this embodiment, the excitation coil 202 is wo...

Embodiment 3

[0065]This embodiment provides a sterilization method using the three-phase continuous flow induction heat green sterilization system given in the first embodiment, and the feed liquid takes fresh milk as an example.

[0066] Specifically, as figure 1 As shown, the adopted three-phase continuous flow induction thermal sterilization system includes: a sample introduction tank 101 , a pump 102 , a three-phase power supply 103 , a sample receiving tank 104 and a sterilization treatment device 200 . The sterilization treatment equipment 200 includes: a three-column magnetic circuit 201 , an excitation coil 202 , a magnetic coupling tube 203 , a material storage tube 204 , a processing chamber 205 , a liquid outlet tube 206 , a three-way connector 207 , a fixing plate 208 and a base 209 .

[0067] The three-pillar magnetic circuit 201 is made of amorphous nanocrystalline soft magnetic material.

[0068] In this embodiment, the exciting coil 202 is wound on the three-column magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| magnetic flux | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com