Automatic temperature control method of electronic atomizer and electronic atomizer applying method

A technology for electronic atomizers and atomizing components, which is applied to tobacco and other directions, can solve the problems of uneven vapor or aerosol, instability, burnt smell of atomizing unit, etc., so as to improve the user experience and prevent dry burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The electronic atomizer with automatic temperature control method in the embodiment of the present invention is used to heat the liquid to be atomized so as to generate atomized steam or aerosol for the user to inhale.

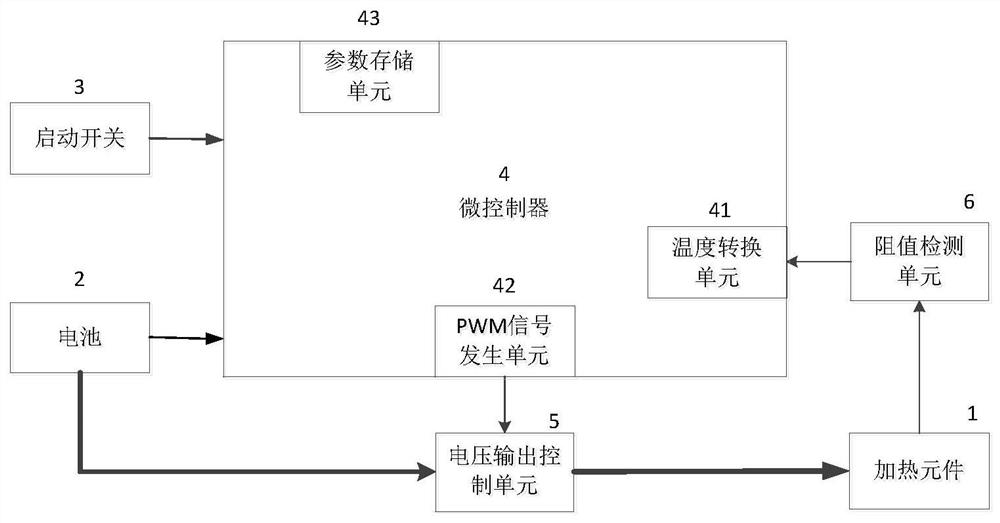

[0036] Such as figure 1 As shown, the electronic atomizer of this embodiment includes a heating assembly and a battery assembly (not shown in the figure), wherein the heating assembly is provided with a heating element 1 for heating the liquid to be atomized, and the heating element 1 is a positive temperature coefficient The thermistor and the battery assembly are provided with a battery 2, a control circuit and a start switch 3, and the control circuit includes a microcontroller 4, a voltage output control unit 5 electrically connected to the microcontroller 4, and a temperature detection unit (not shown). The temperature detection unit in this embodiment includes a resistance value detection unit 6 and a temperature conversion unit 41 provided in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com