Turning plate type monorail mud scraper

A flap-type and mud scraper technology, which is applied to the feeding/discharging device, chemical instrument and method, and separation method of the settling tank, can solve the technical requirements, installation and maintenance of mud scraping that cannot be realized in part-stroke and full-stroke combined Complicated maintenance, occupying a lot of ground space, etc., to reduce the layout of electromechanical sensors and cable laying, save installation space, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

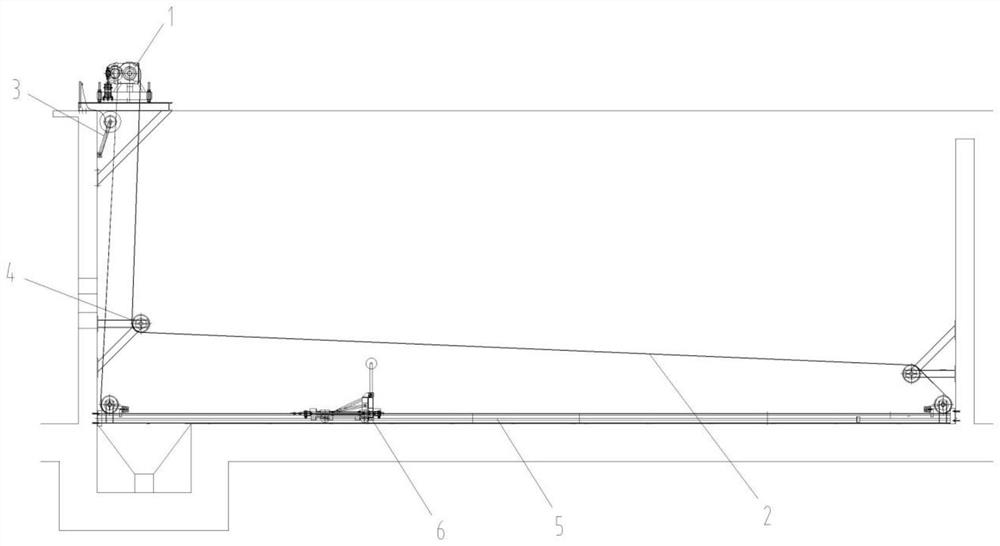

[0042]Examples such asfigure 1 The shown turning plate type monorail scraper includes a drive device 1, a traction chain 2, a trolley scraper assembly 6, and further includes a reversing gear train 4, a track assembly 5, and a tensioning device. The drive device 1 is set on the top of the water inlet end of the sedimentation tank, the reversing gear train 4 is set at both ends of the sedimentation tank, and the traction chain 2 is set on the driving device 1, the reversing gear train 4 and scraped with the trolley The plate assembly 6 is connected, the track assembly 5 is arranged in the middle of the bottom of the sedimentation tank along the length of the tank, the trolley scraper assembly 6 is installed on the track assembly 5, and the tensioning device is manually tensioned. Composed of a tensioning device and an automatic tensioning device, the automatic tensioning device is composed of a pendulum tensioning device 3 and a large-span suspension structure;

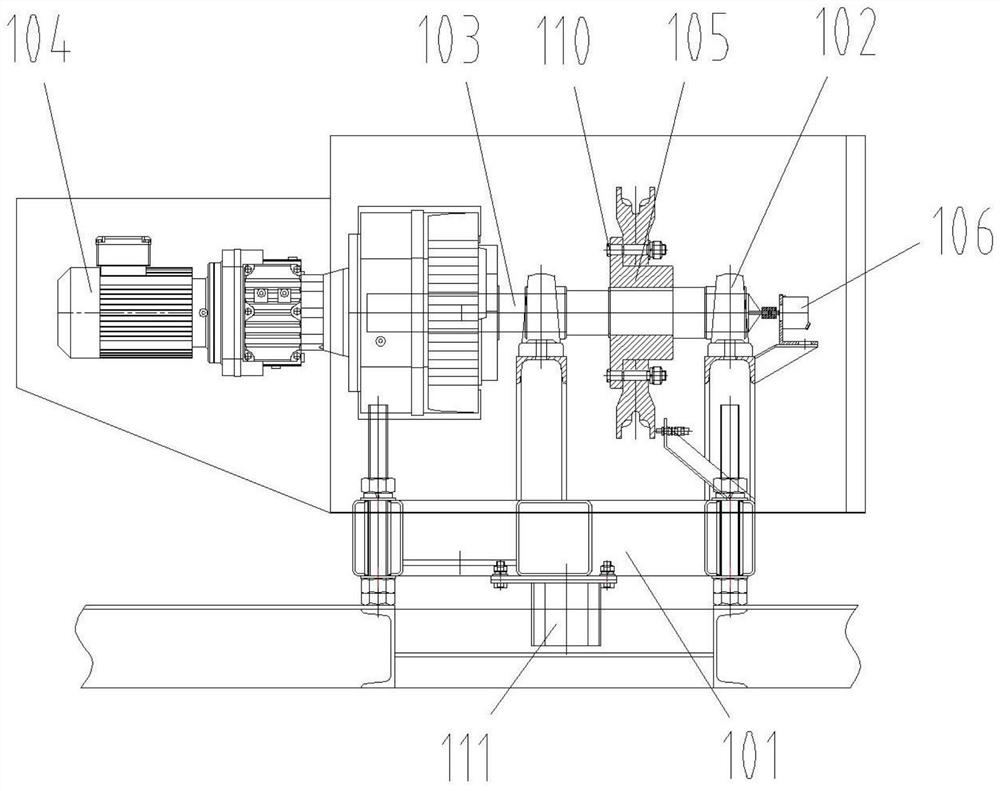

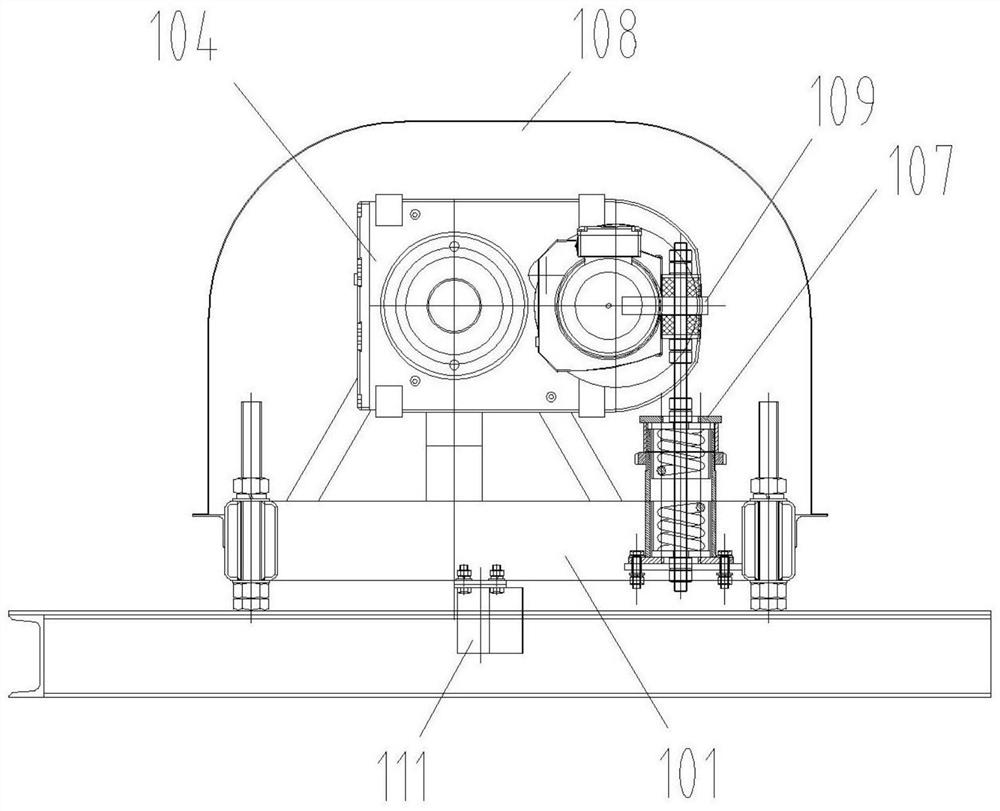

[0043]Such asFigure 2~4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com