A solid co2 cleaning nozzle structure

A technology for cleaning nozzles and CO2, applied in the direction of spraying devices, spraying devices, etc., can solve problems such as unsatisfactory cleaning requirements, different pressures, large dry ice particles, etc., to improve the convenience and applicability of use, improve applicability, and improve The effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

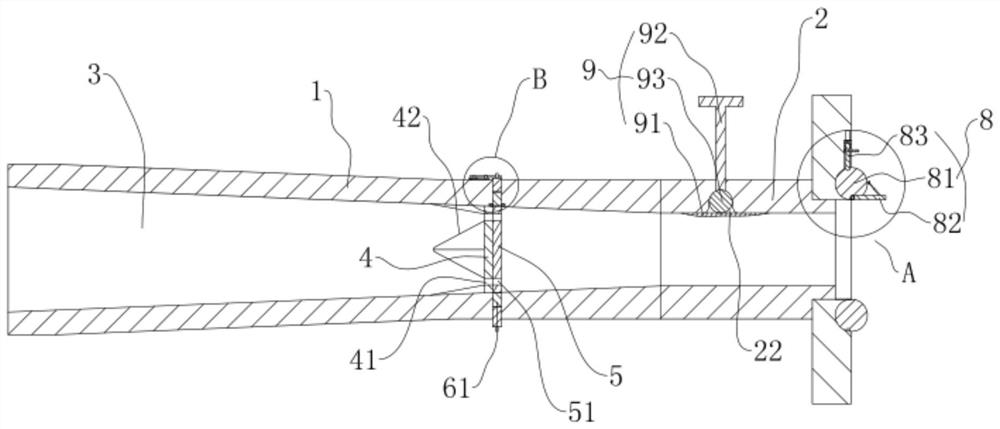

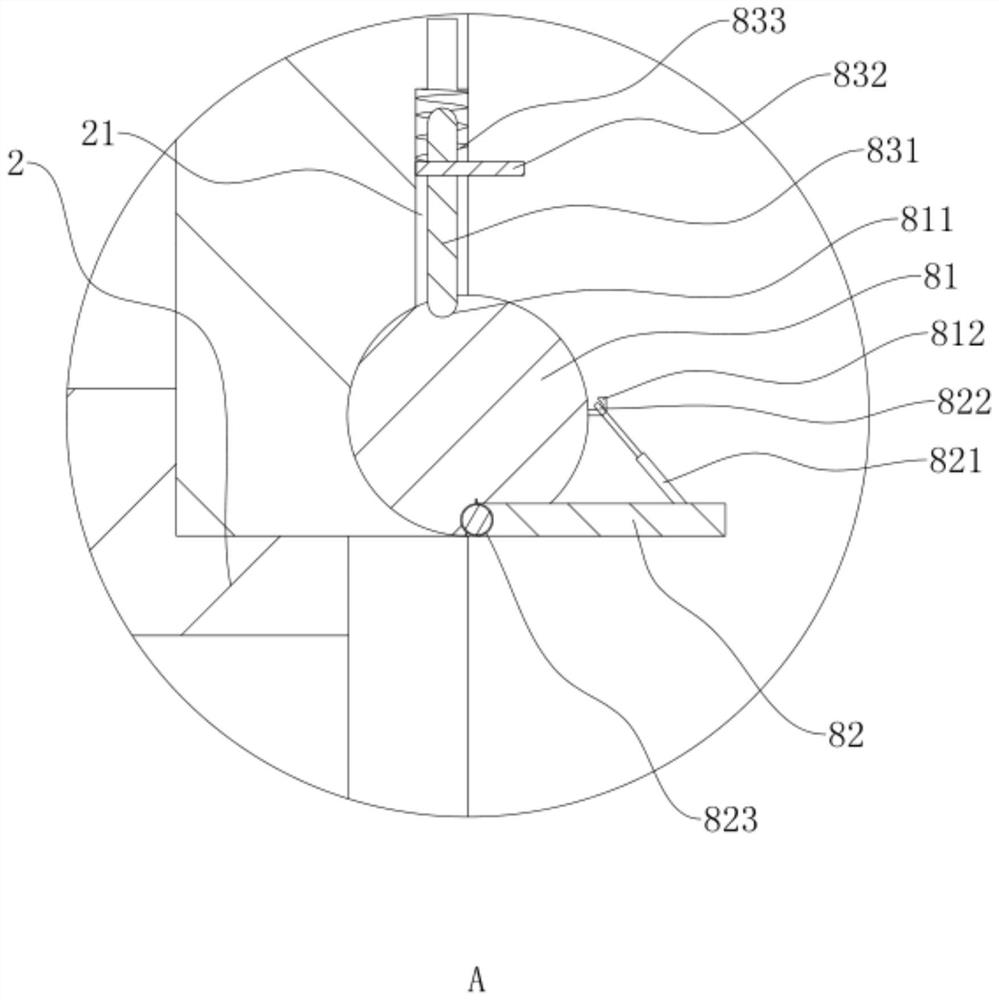

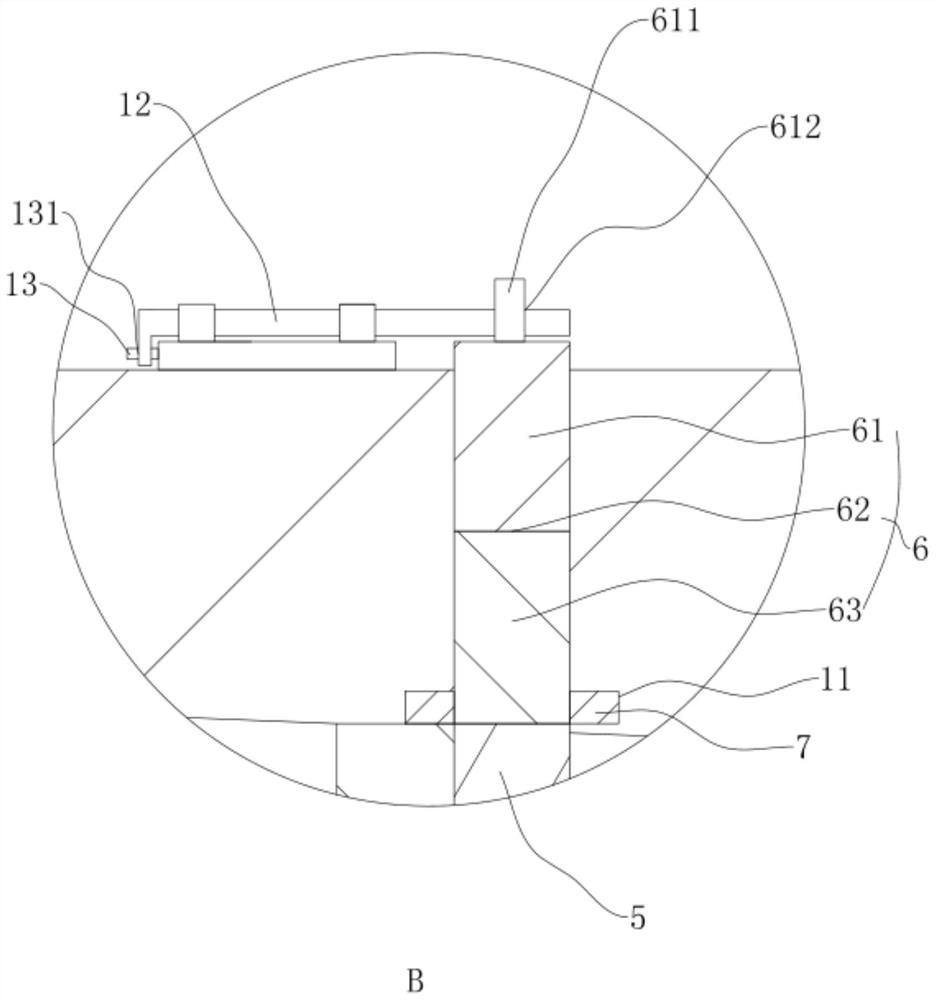

[0028] refer to Figure 1 to Figure 4 The structure of the solid CO2 cleaning nozzle is further explained.

[0029] A solid CO2 cleaning nozzle structure, such as figure 1 As shown, it includes a nozzle body 1 and a nozzle seat 2 connected to one end of the nozzle body 1. The end of the nozzle body 1 away from the nozzle seat 2 is set as the inlet side 3 for the inflow of dry ice particles and air, so as to feed in dry ice particles. Nozzle seat 2 sprays out to carry out dry ice blasting operation.

[0030] like figure 1 As shown, the end of the nozzle body 1 close to the nozzle seat 2 is provided with a crushing baffle 4, and a plurality of through holes 41 are uniformly distributed along its circumferential direction on the crushing baffle 4, so that when the dry ice passes through the through holes 41, further Cutting and refining, forming uniform dry ice particles into the nozzle seat 2 for spraying. Among them, a plurality of crushing knives 42 are uniformly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com