A welding device and method for argon arc welding with double-weld expansion core support

A welding device, argon arc welding technology, applied in the direction of welding equipment, welding equipment, auxiliary equipment, etc., to achieve the effect of ensuring the heat dissipation of the weld, the appearance is simple, and the welding quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

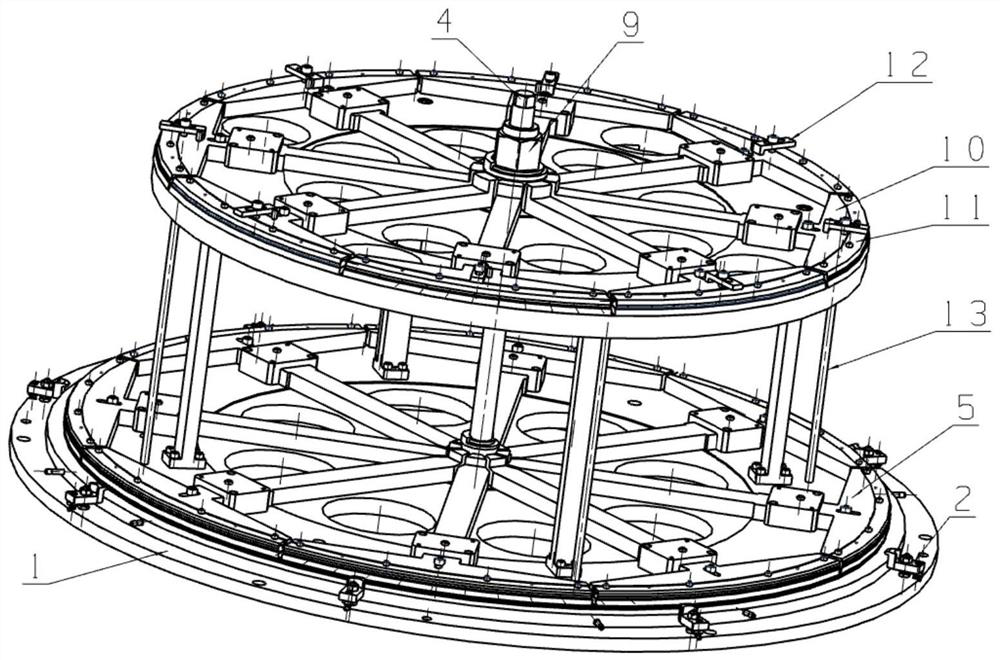

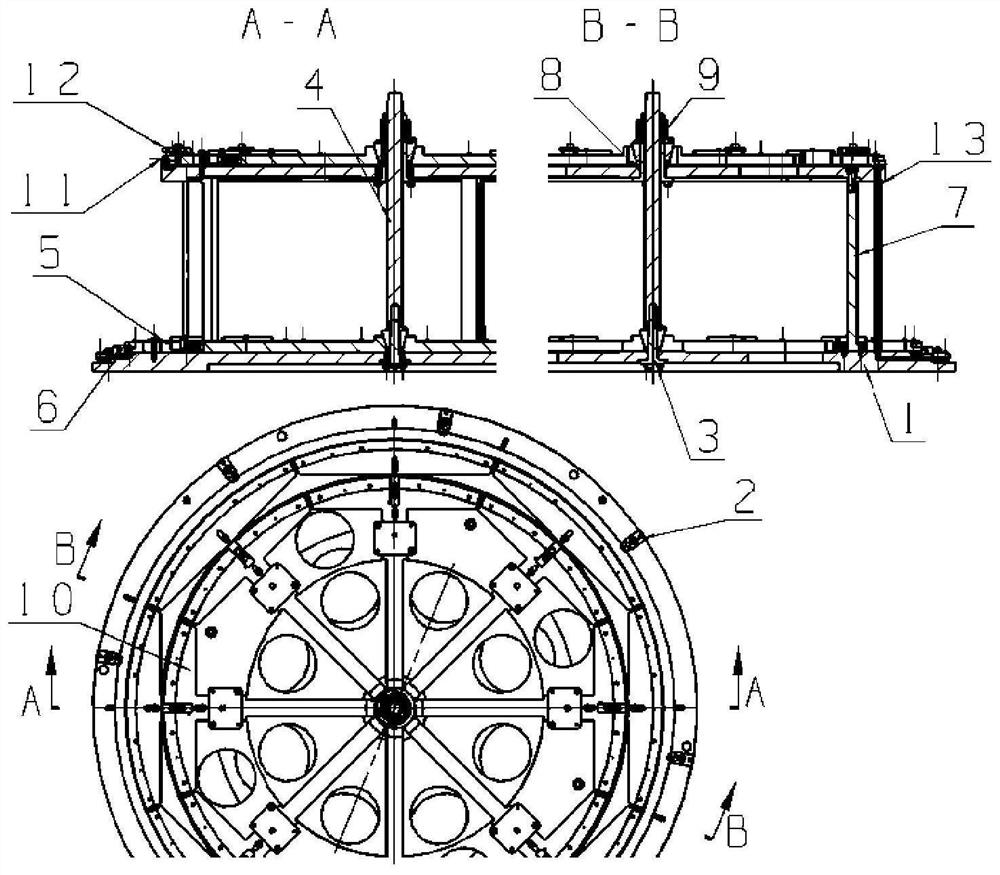

[0034] like Figure 2 to Figure 7As shown, the welding device is a double-layer core expansion structure with a diameter of 1500 mm, including a lower core expansion mechanism 5, an upper core expansion mechanism 10 and a long rod nut provided between the lower core expansion mechanism 5 and the upper core expansion mechanism 10 4. A positioning bracket 7 is provided on the lower core expanding mechanism 5, the positioning bracket 7 supports the upper core expanding mechanism 10, and a hollow positioning shaft 8 is provided in the center of the upper core expanding mechanism 10. The hollow positioning shaft The center of 8 is provided with a through hole 705, and the outer side of the hollow positioning shaft 8 is provided with an upper-layer opening and closing nut 9, which is used to control the opening and closing of the upper-layer core expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com