A turret with a long service life

A long-life, turret technology, used in manufacturing tools, metal processing machinery parts, positioning devices, etc., can solve the problem of impurities easily entering the inside of the turret, reducing the service life of the turret, affecting the sealing effect, etc., to ensure normal safety. The effect of working, improving the service life and preventing the damage of the turret

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

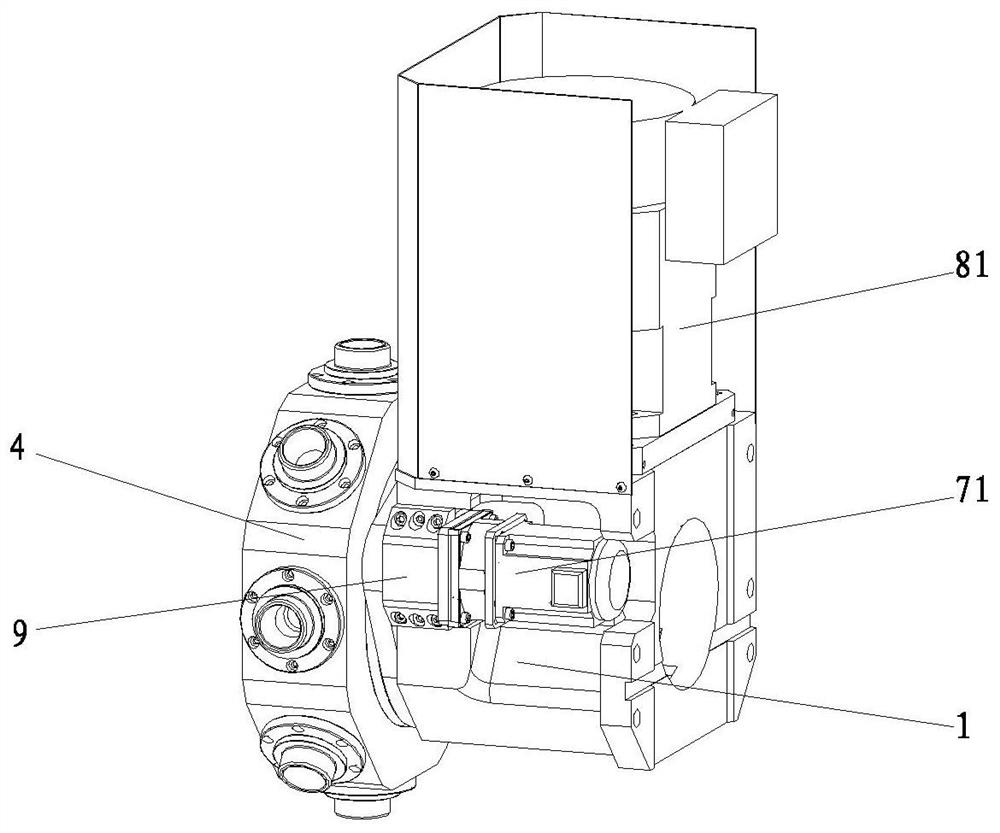

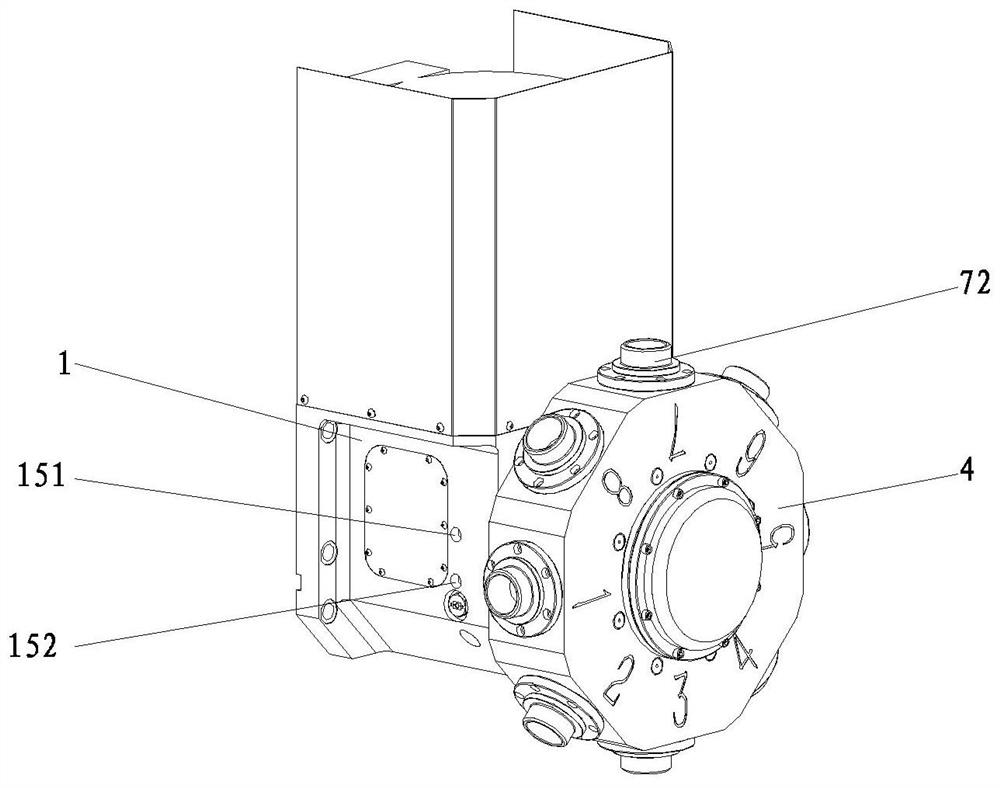

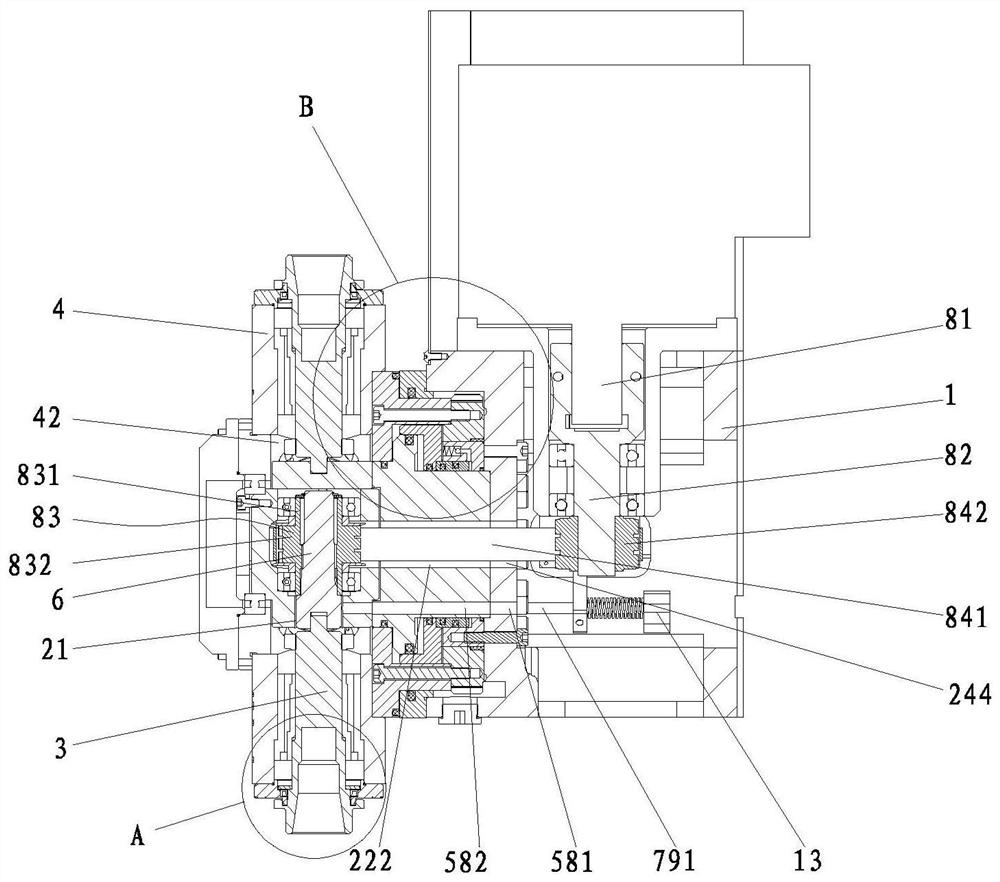

[0060] like Figure 1-13 As shown, a turret with a long service life includes a main box 1, a bearing seat 2, a main shaft 3 and a cutter head 4, the bearing seat 2 is connected with the main box 1, and the cutter head 4 is sleeved outside the bearing seat 2, The outer surface of the cutter head 4 is provided with a plurality of installation holes 41 for the main shaft 3 to be inserted into, among which, it also includes a sealing mechanism arranged on the installation holes 41 and a self-lubricating driving mechanism for driving the cutter head 4 to rotate. The seat 51, the mounting seat 51 is provided with a first through hole 511, the main shaft 3 has a lower end portion 31 extending into the first through hole 511, and a first gap 52 is formed between the first through hole 511 and the outer side surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com