Epoxy anticorrosive primer and production process thereof

An anti-corrosion primer and epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of weak bonding between epoxy primer coatings and base metal, and prone to local corrosion. Achieve the effect of preventing corrosion acceleration and repairing primer cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

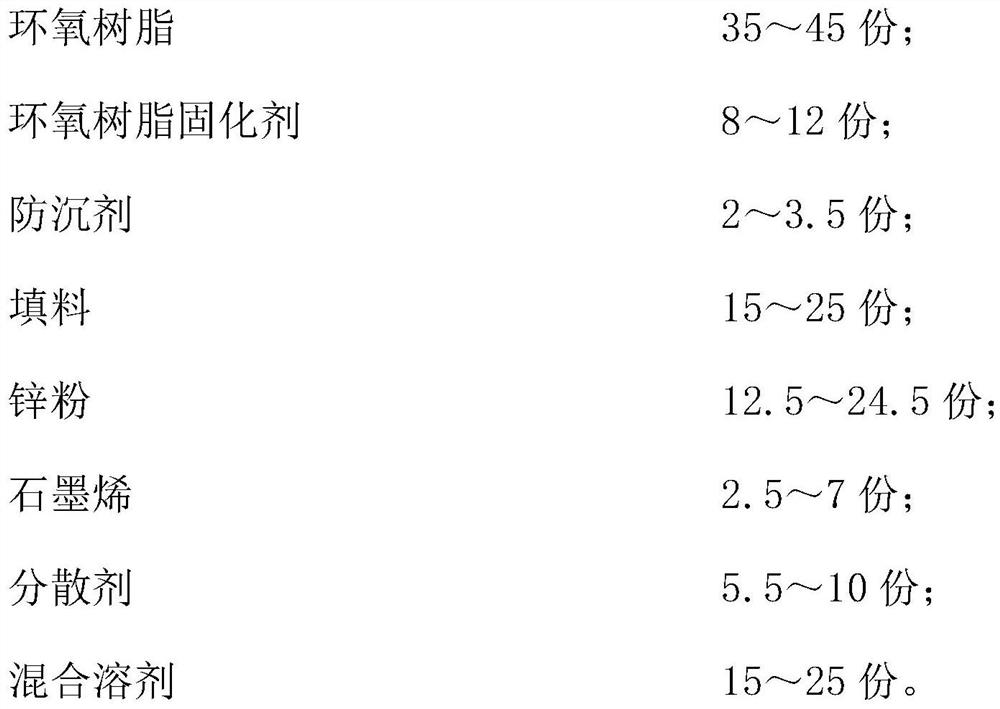

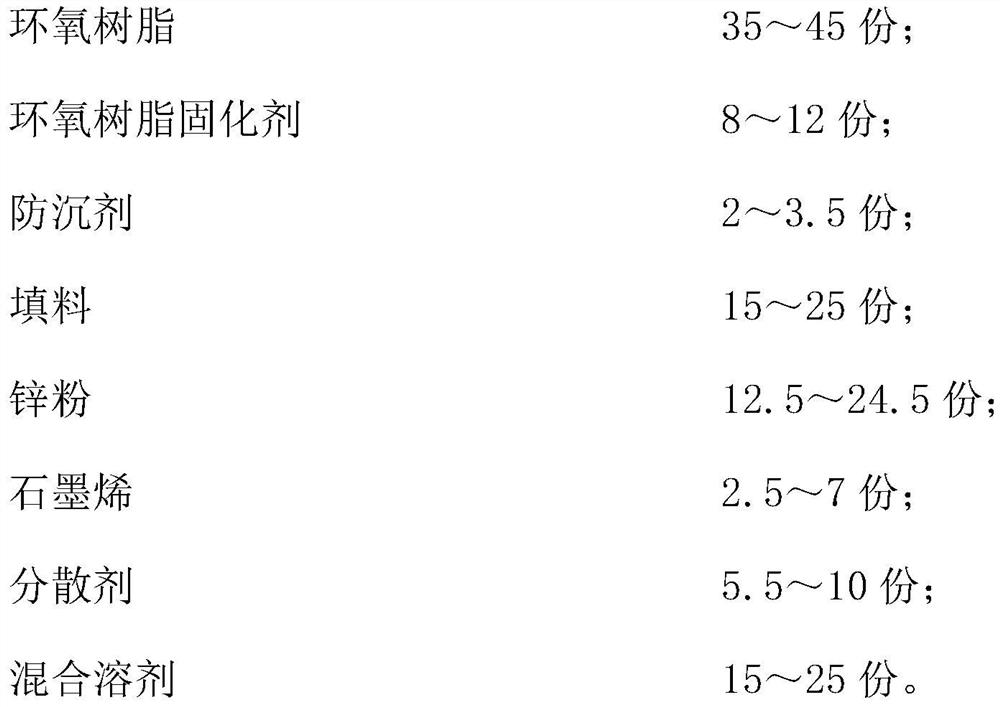

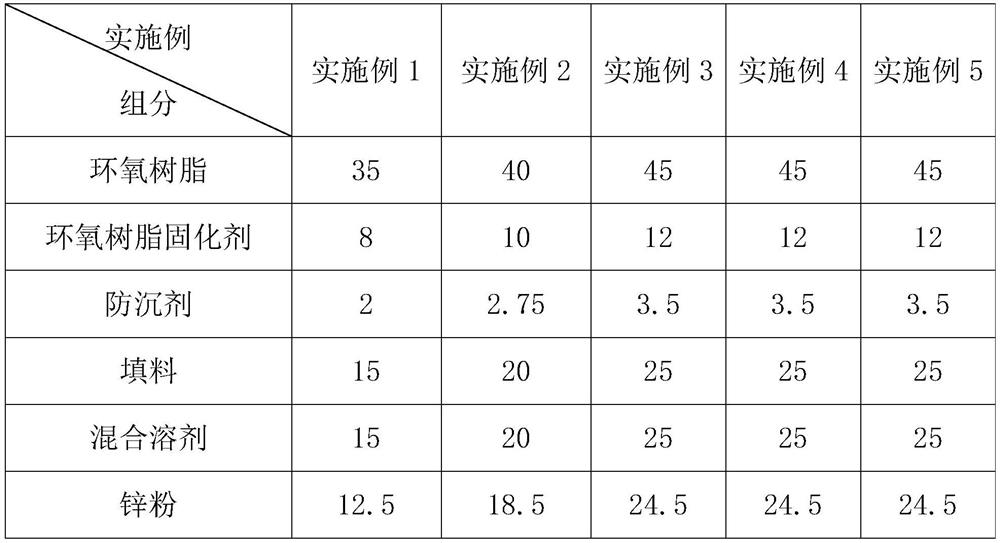

[0050] An epoxy anticorrosion primer in Examples 1 to 3 is prepared from the following components: epoxy resin, epoxy resin curing agent, anti-settling agent, filler, antirust material, and mixed solvent.

[0051] Its specific component content (unit: kg) is shown in Table 1.

[0052] Table 1

[0053]

[0054]

[0055] Self-healing microcapsules use epoxy resin as the core material and urea-formaldehyde resin as the wall material.

[0056] The production technology of epoxy anticorrosion primer in embodiment 1~5, comprises the following steps:

[0057] S1: mix the raw materials of the anti-rust material in proportion to obtain the anti-rust material;

[0058] S2: Mix the epoxy resin, anti-sedimentation agent, filler, anti-rust material and mixed solvent evenly in proportion;

[0059] S3: Add an epoxy resin curing agent to the mixed solution obtained in step S2, and stir evenly to obtain an epoxy anticorrosion primer.

Embodiment 6

[0061] The difference from Example 1 is that the self-healing microcapsules are pretreated with ethylenediamine and then mixed with other components in step S1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap