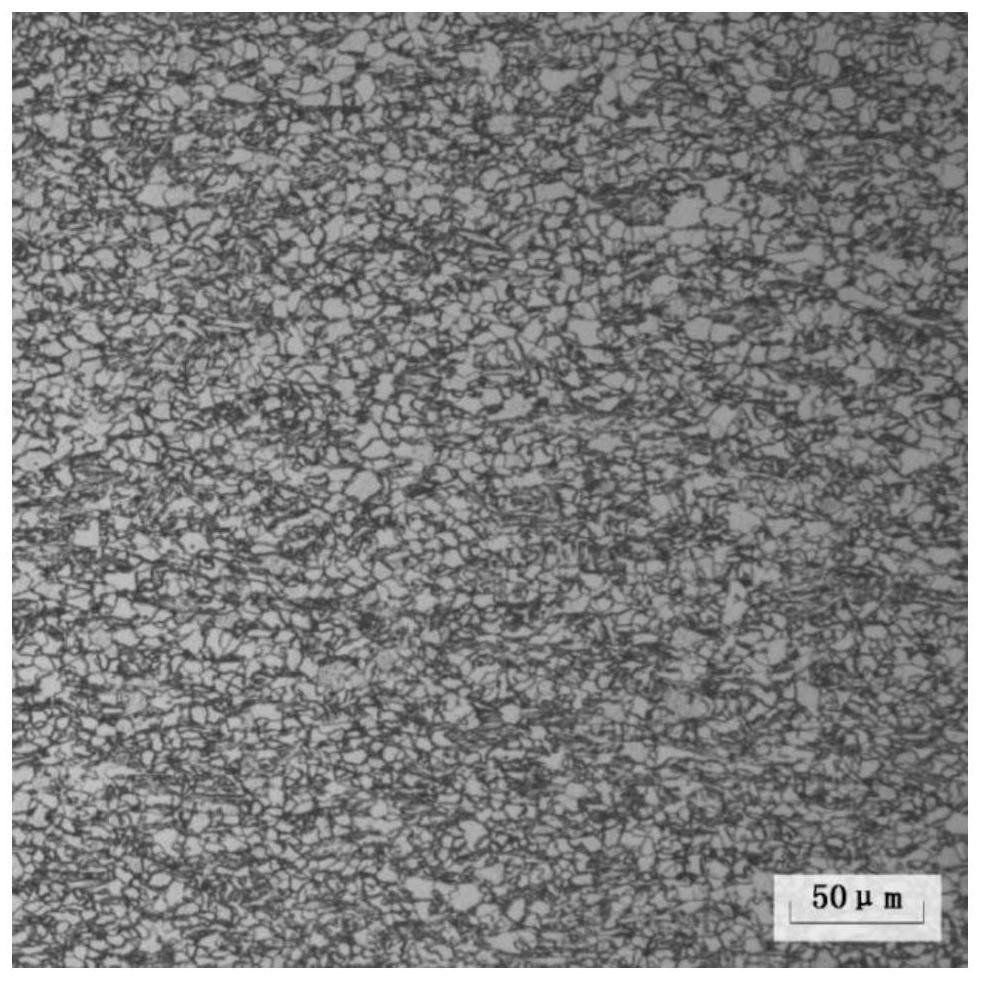

A kind of high-strength low-hardness hydrogen sulfide corrosion-resistant steel and its preparation method

A hydrogen sulfide-resistant, low-hardness technology, applied in the field of steel preparation, can solve the problems of increased hardness, low hardness, and high strength of hydrogen sulfide-resistant steel, so as to achieve low hardness, improve service life and safety, and excellent Effect of Hydrogen Sulfide Corrosion Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] According to another typical embodiment of the present invention, the present invention also provides a preparation method of the high-strength low-hardness hydrogen sulfide corrosion-resistant steel, the preparation method comprising:

[0049] obtaining the cast slab of the high-strength, low-hardness hydrogen sulfide corrosion-resistant steel, the total compression ratio of the cast slab is ≥10;

[0050] The slab is heated before rolling, rolled and cooled after rolling to obtain high-strength and low-hardness hydrogen sulfide corrosion-resistant steel,

[0051] The rolling includes rough rolling, intermediate billet cooling, intermediate rolling and finish rolling,

[0052] The total compression ratio of the stretching stage in the rough rolling is ≤30%, and the total compression ratio of the longitudinal rolling after the stretching is ≥45%;

[0053] The intermediate billet is cooled at a cooling rate of 1-5°C / s;

[0054] The intermediate rolling and finishing rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com