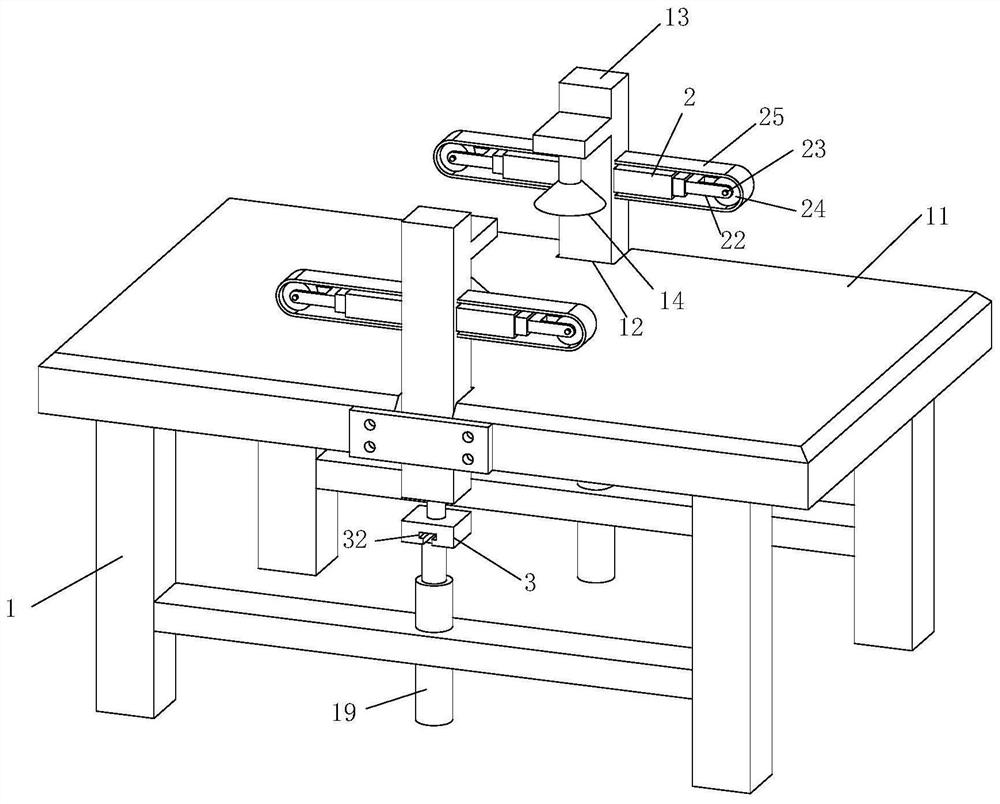

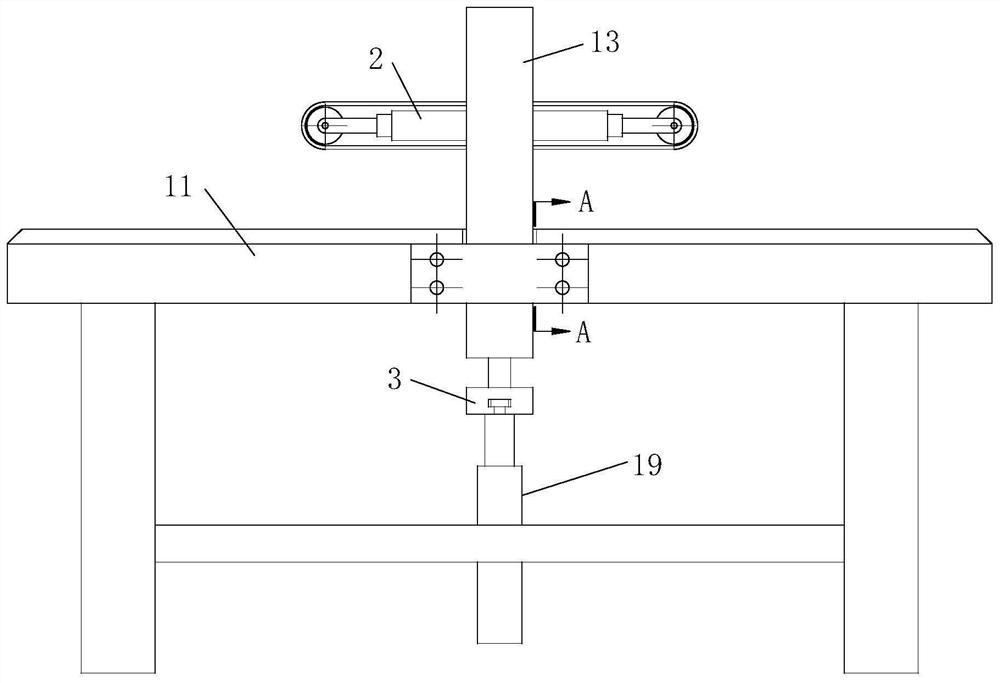

Garment tailoring auxiliary negative pressure clamping device

A clamping device and clothing technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of reducing the yield of cloth cutting, reducing the cutting precision of the cloth, and the cloth is easy to form wrinkles, etc., so as to increase the cutting and clearing effect, increase the Cutting precision and cutting efficiency, the effect of increasing the leveling range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

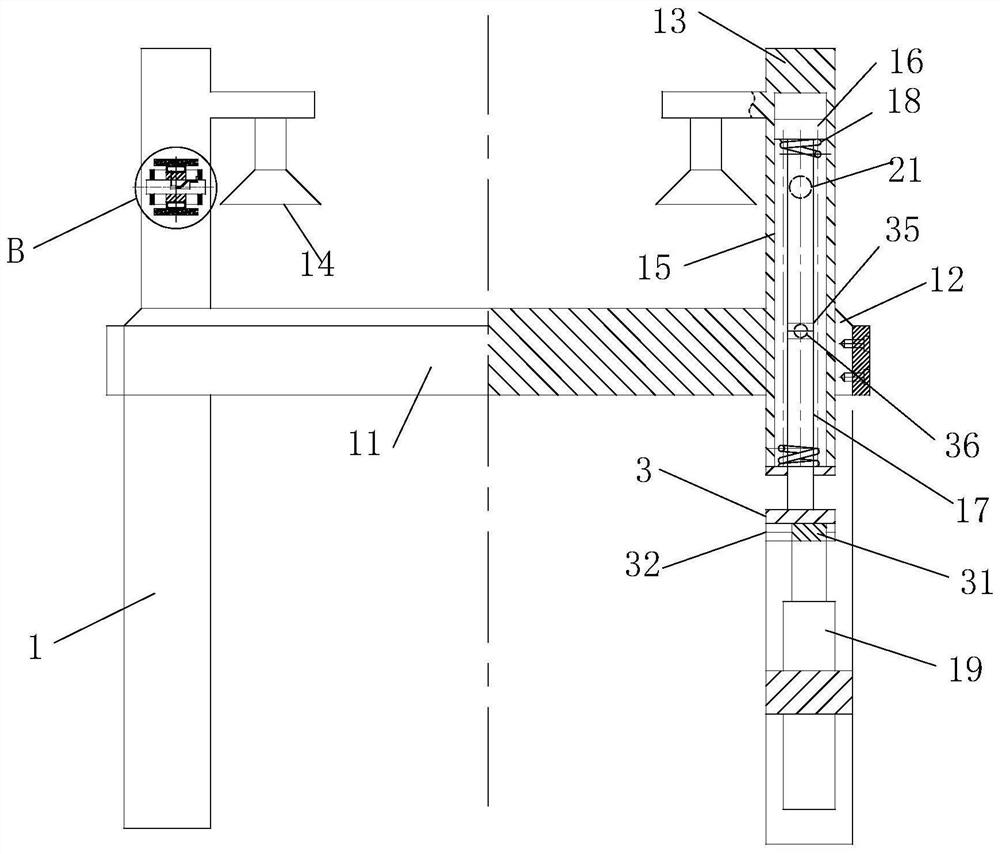

[0029] As an embodiment of the present invention, a slide table 3 and a slide block 31 are provided between the piston rod 17 and the No. 1 cylinder 19, the slide table 3 is fixedly connected with the piston rod 17, and the slide block 31 is connected to the top of the No. 1 cylinder 19. Fixed connection; the slide block 31 is slidingly connected with the trapezoidal groove 32 provided at the bottom of the slide table 3; a group of chute 33 is provided on both sides of the chute 12, and the bottom of the chute 33 is inclined to the side away from the center of the workbench 11; The position corresponding to the chute 33 on the vertical rod 13 is fixedly connected with a revolving pin 34, and the revolving pin 34 is slidably connected with the chute 33; 34 slides in the chute 33, cooperates with the sliding block 31 to slide laterally in the trapezoidal groove 32, so that the vertical rod 13 slides in a direction away from the center of the workbench 11, and further stretches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com