Road construction pavement crushing device

A crushing device and road construction technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of long time consumption, energy waste, low crushing efficiency, etc., and achieve the effect of improving stability and increasing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

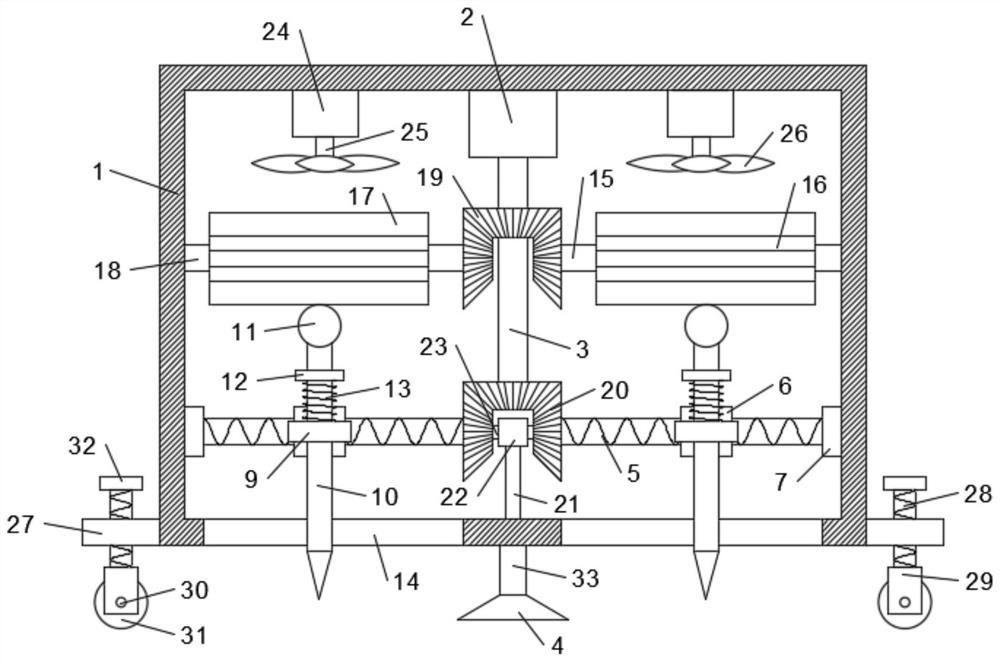

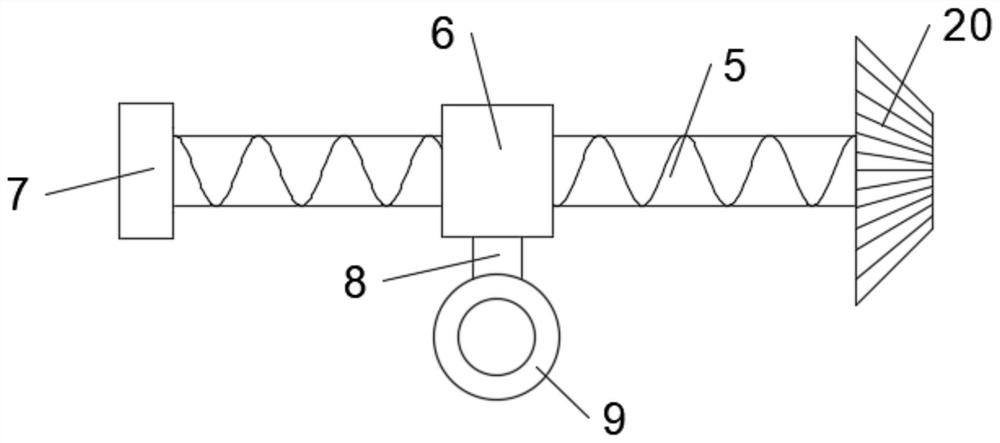

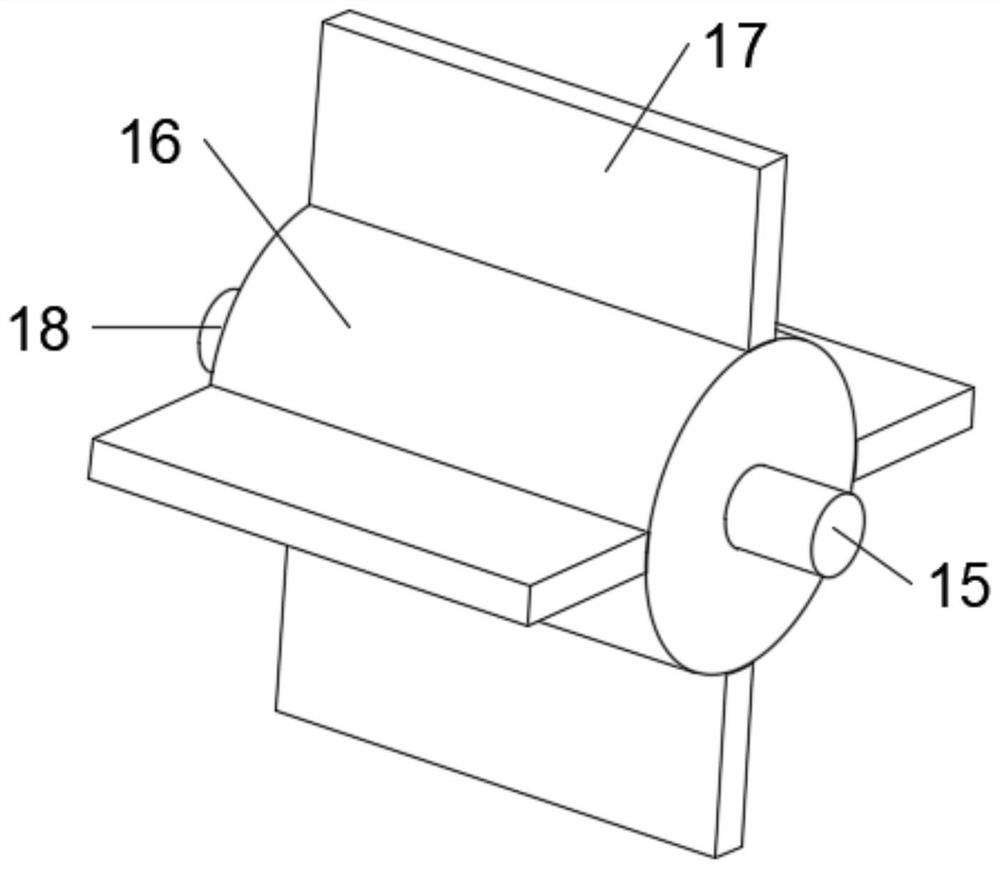

Embodiment 1

[0020] see Figure 1-3 , in an embodiment of the present invention, a road construction pavement crushing device includes a box body 1, a motor-2 is arranged on the inner top of the box body 1, and a shaft-3 is fixedly connected to the output end of the motor-2, and the shaft-3 There are a plurality of linkage devices on the upper side, the lower linkage device is fixedly connected with the screw rod 5, the slider 6 is slidably installed on the screw rod 5, the slider 6 is provided with an impact device, and the upper linkage device is fixedly connected with the driving device , start the motor one 2, make the shaft rod one 3 drive the driving device through the upper linkage device to drive the impact device, make it move downward, impact and break the ground, and the lower linkage device makes the screw rod 5 rotate, and then the slider 6 Drive the impact device to move left and right, so that the impact device moves left and right while crushing the ground, increasing the r...

Embodiment 2

[0028] In order to improve the stability of the device, this embodiment is further improved on the basis of Embodiment 1. The improvement is: the lower end of the box 1 is provided with a fixed rod 33, and the end of the fixed rod 33 is fixedly connected to the base 4. When the box body 1 is fixed at this position, the handle 32 can be rotated to rotate the screw rod 28 and drive the roller 31 to move upwards so that the base 4 touches the ground to prevent the roller 31 from rolling and cause the box body 1 to slide, thereby improving the stability of the device.

[0029] The working principle of this embodiment is: in order to improve the stability of the device, a fixed rod 33 is provided at the lower end of the box body 1, and the end of the fixed rod 33 is fixedly connected with the base 4, when the box body 1 needs to be fixed at this position , the handle 32 can be rotated to rotate the screw rod 28, and drive the roller 31 to move upward, so that the base 4 touches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com