Milling machine slotting warning device

An early warning device and a technology of milling and excavating machines, which are applied in the direction of earthmoving machines/shovels, construction, etc., can solve the problems of inconsistent standards, irregular arc grooves, over- or under-digging, etc. Type rules, the effect of preventing over-digging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following specific embodiments may be combined with each other, and the same or similar concepts or processes may not be repeated in some embodiments. Embodiments of the present invention will be described below with reference to the accompanying drawings.

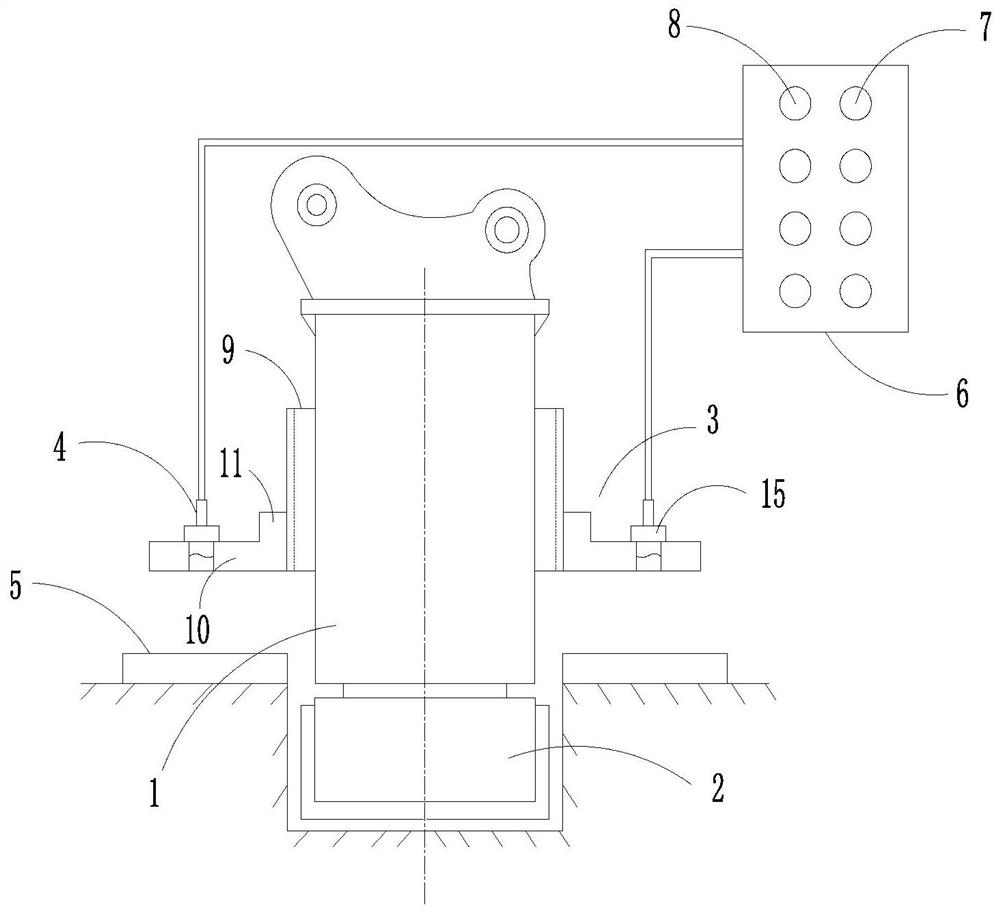

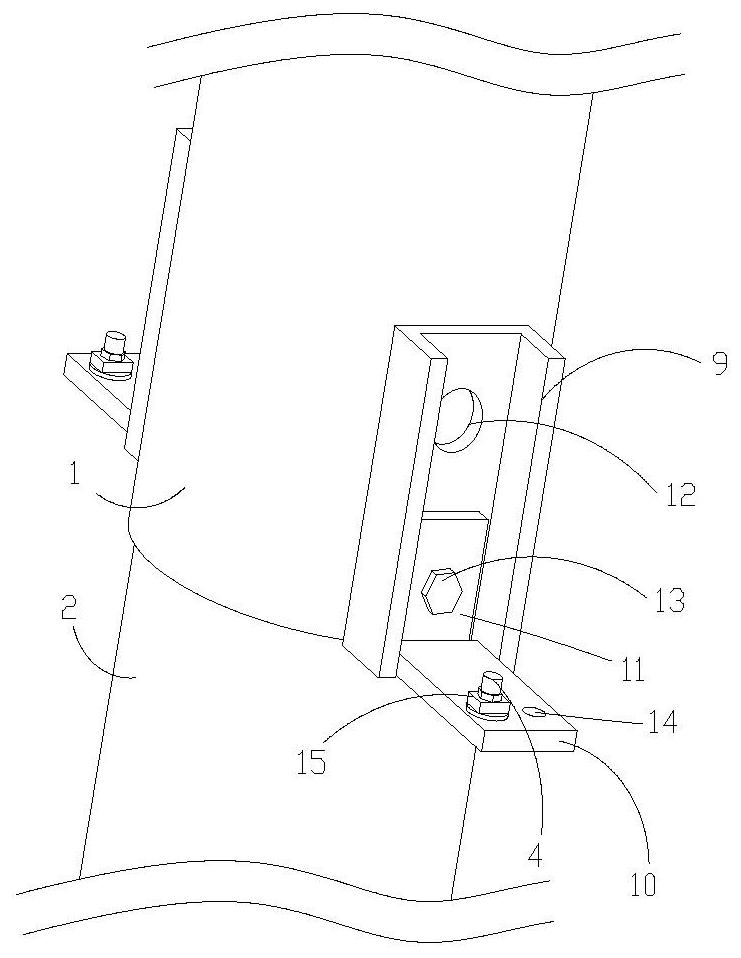

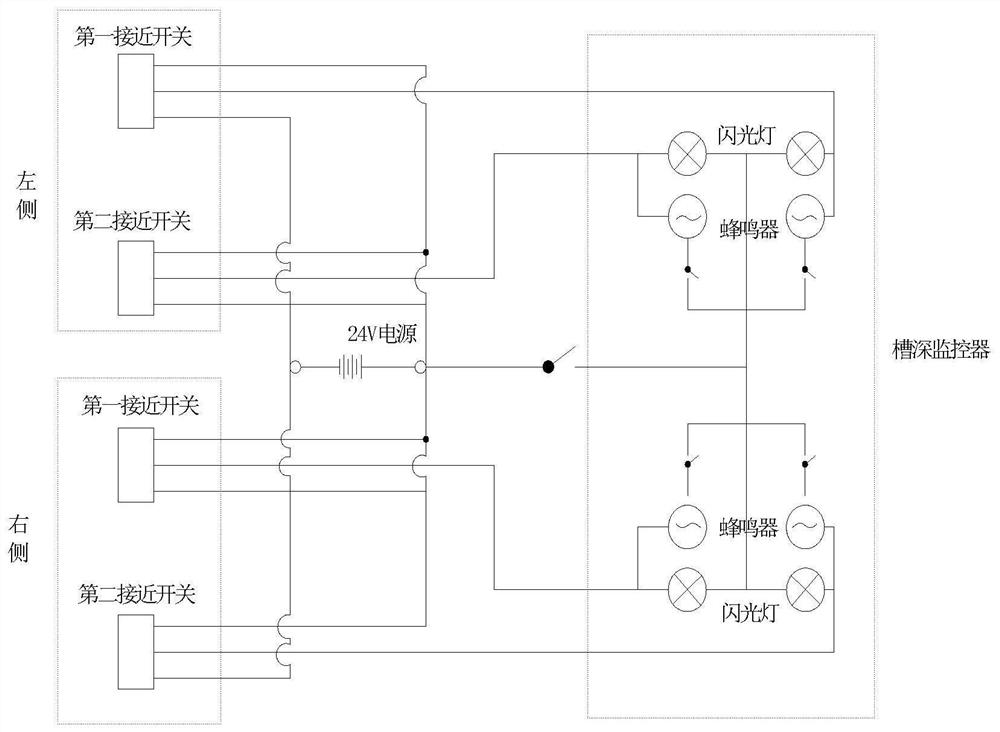

[0024] Such as figure 1 As shown, the present invention discloses a grooving warning device for a milling machine. 1 is a hollow shell, the interior of the milling head 1 is provided with a transmission mechanism for driving the roller shaft 2, and the transmission mechanism is connected with the power part of the excavator; For the drill bit for excavating trenches, the drill bits are arranged at intervals on the blade side of the helical blade. The specific structure of the drill bit and the helical blade can be found in Chinese patent CN201920248784. An adjustment bracket 3 is provided on the outer surface of the milling head 1, and a distance sensor 4 is installed on the adjustment bracket 3. The distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com