Hinge and automobile

A technology of hinges and rotating parts, which is applied in the field of hinges, and can solve the problems of screw 103 rusting, reducing product delicacy, and damaging the screw paint surface, etc., and achieves the effects of convenient assembly and disassembly, convenient and fast assembly, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described in more detail below. Although preferred embodiments of the present invention are described below, it should be understood that the present invention can be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

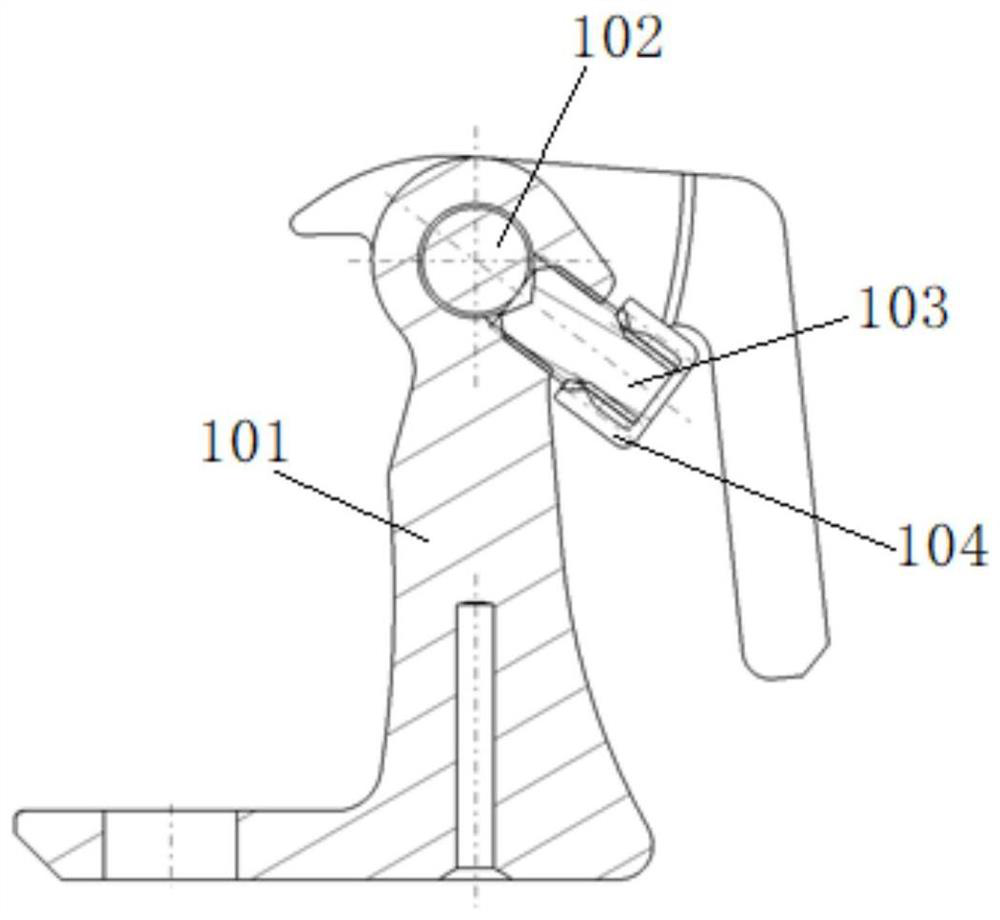

[0039] Such as figure 1 As shown, the body leaf 101 and the pin shaft 102 of a car door hinge in the prior art are fixed by screws 103, and if the body leaf 101 and the pin shaft 102 are to be disassembled, the screw 103 needs to be twisted; not only the operation Inconvenient, inefficient, and easy to damage the paint surface and appearance of the screw 103 and the door hinge.

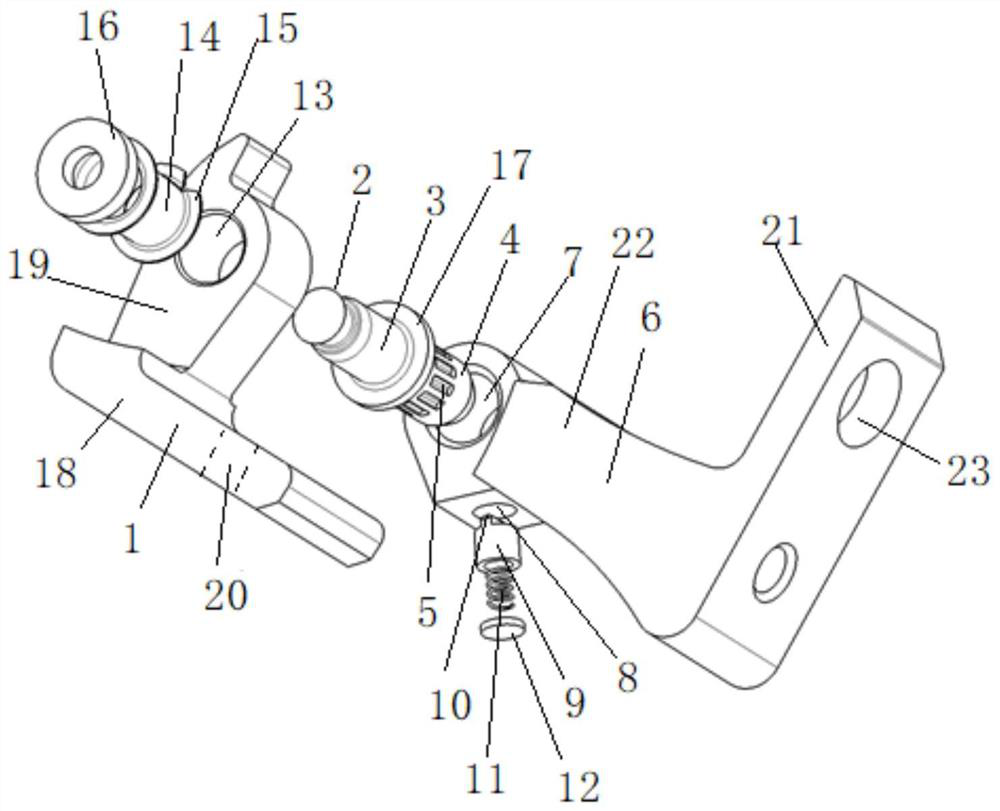

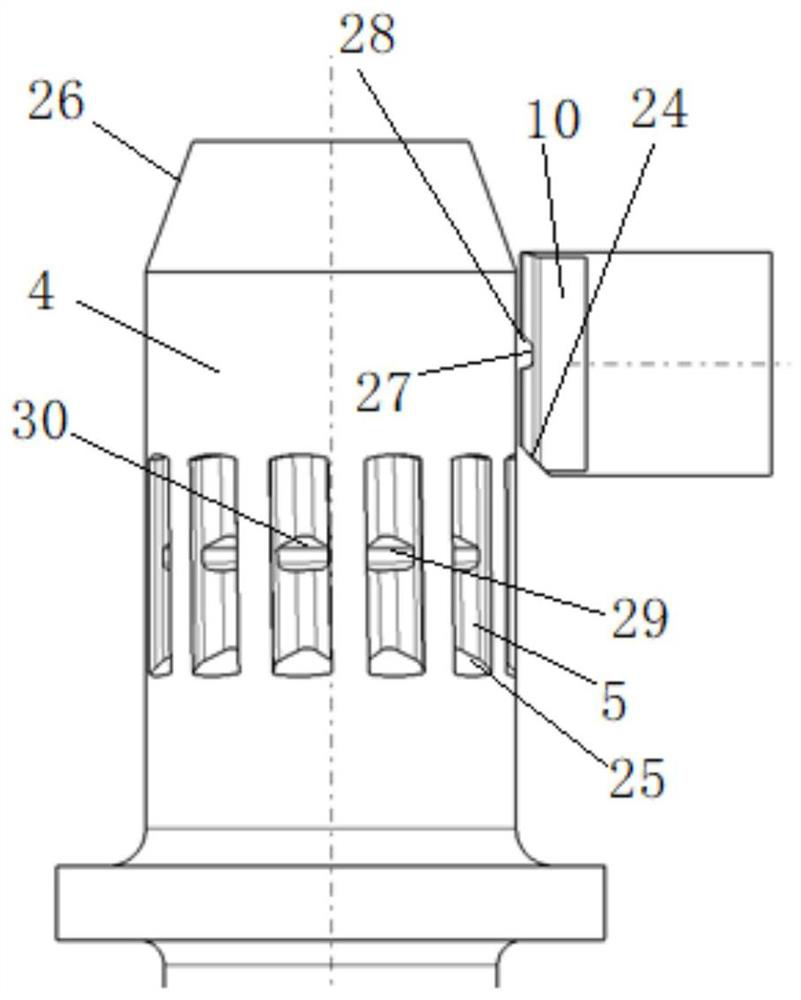

[0040] To solve the above problems, such as Figure 2 to Figure 4 As shown, the present invention provides a hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com