Electronic water pump

An electronic water pump and pump cover technology, applied in the field of auto parts, can solve the problems of wear of the rotating shaft and the shaft sleeve, reduce the service life, difficult to eliminate, etc., and achieve the effect of prolonging the service life, speeding up the flow rate, and improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

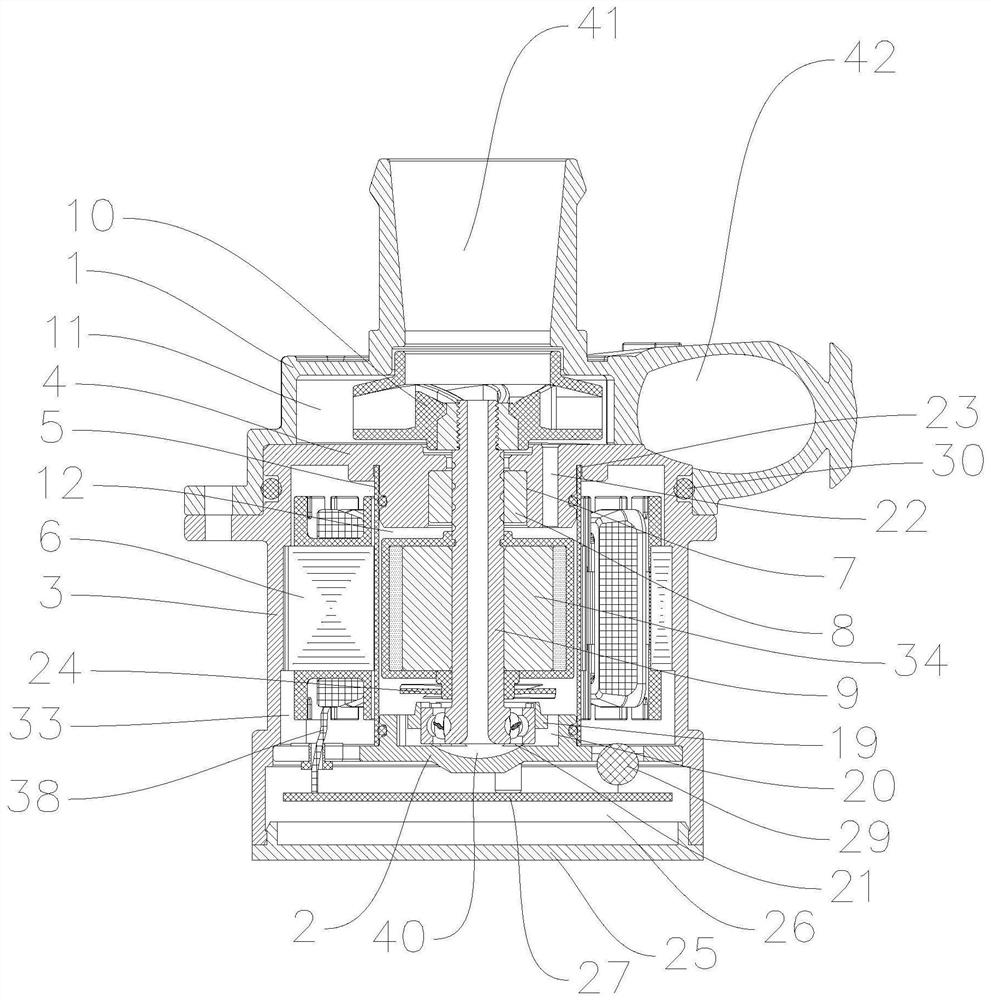

[0030] Such as Figure 1-5As shown, this embodiment discloses an electronic water pump, including: a housing, a pump cover 1 and a rear cover 2, the housing includes a housing body 3 and a housing upper cover 4, and the housing body 3 The upper cover 4 of the housing can be integrally formed or fixedly installed split type, and in this embodiment, it is integrally formed; the pump cover 1 is formed with a water inlet 41 and a water outlet 42, and the pump cover 1 1 is installed on the housing, when installed, the pump cover 1 and the housing are sealed by the pump cover sealing ring 30, and the pump cover 1 and the housing enclose the impeller cavity 11; The housing upper cover 4, the housing cylinder body 3 and the rear cover 2 enclose an accommodation cavity, and an isolation sleeve 5 is arranged in the accommodation cavity, and the isolation sleeve 5 is placed in the accommodation cavity. The fixing method inside is not specifically limited. In this embodiment, a spacer sl...

Embodiment 2

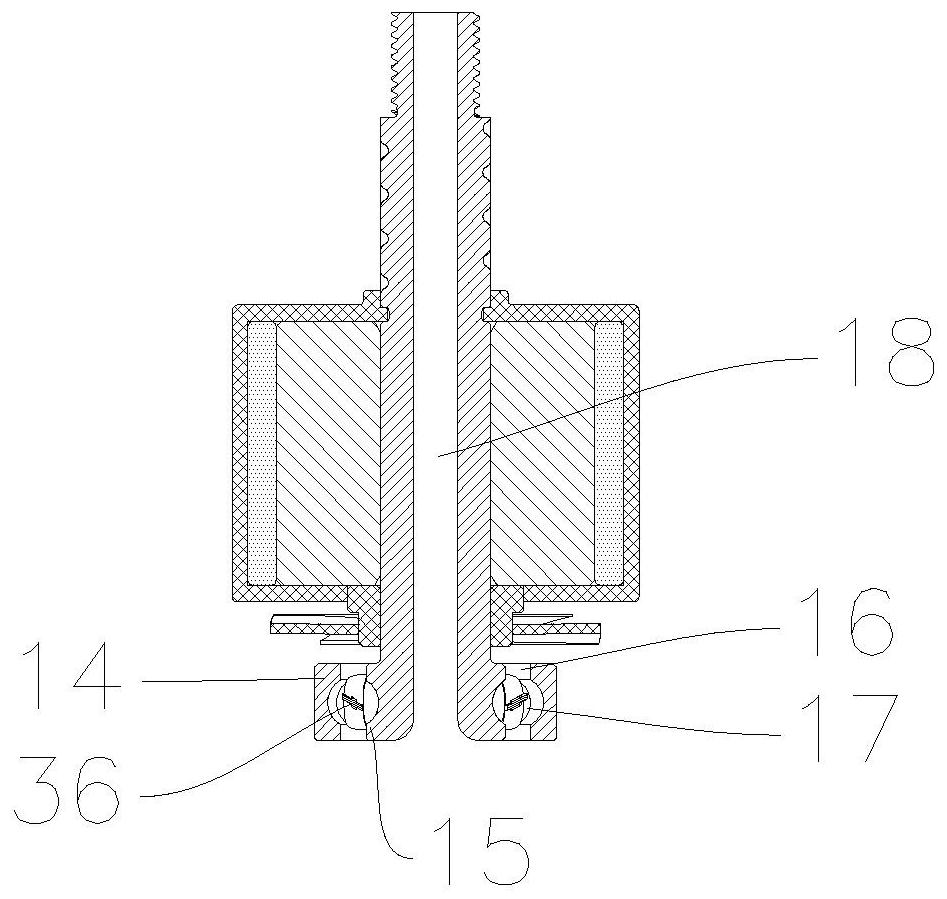

[0039] This embodiment discloses an electronic water pump, which differs from the electronic water pump provided in Embodiment 1 in that: a second helical groove is formed on the inner hole wall of the upper bushing 8 (shown in the figure). ), the helical channel is formed by the cooperation of the second helical groove (not shown in the figure) and the rotor shaft 9 .

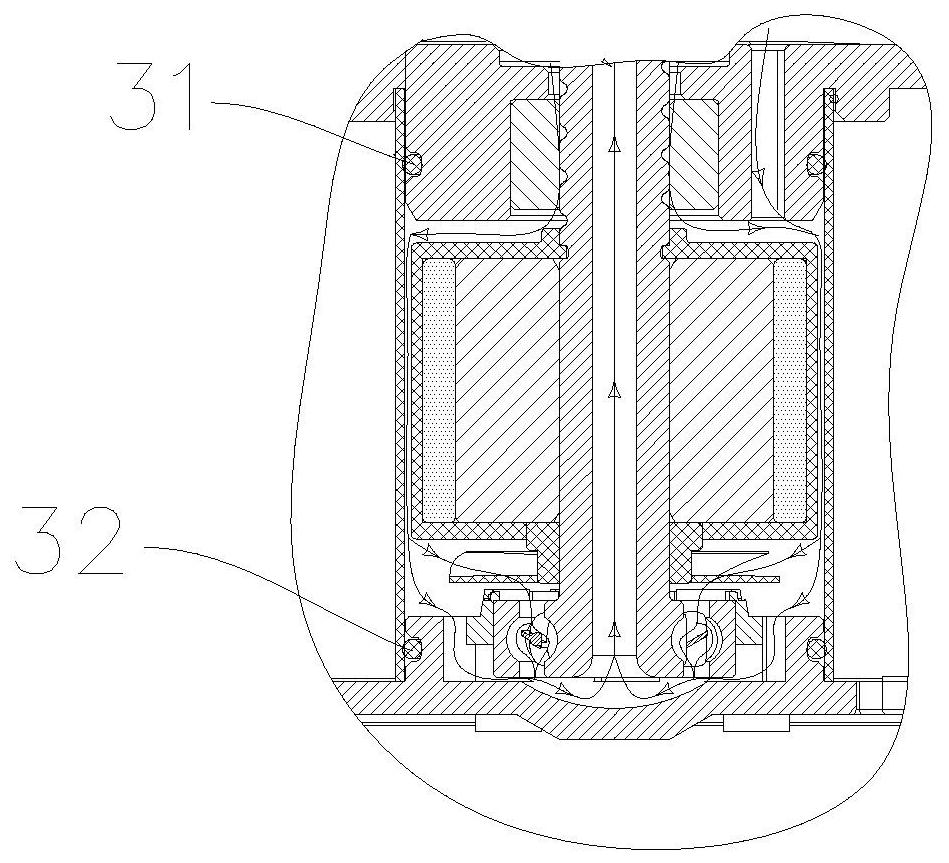

[0040] Such as Figure 1-5 As shown, when working, the stator 6 generates a magnetic field after being energized to drive the rotor block 34 and the rotor shaft 9 to rotate, and the bearing inner ring 15 also rotates accordingly; the water flow flows into the impeller from the water inlet 41 In the cavity 11, after the water in the impeller cavity 11 is stirred by the impeller 10, part of the water flow is discharged from the water outlet 42, and the other part of the water flow passes between the rotor shaft 9 and the upper bushing 8 respectively. The formed gap water flow channel and the liquid hole 22 then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com