Nozzle and gas stove using same

A gas stove and nozzle technology, applied in the field of gas stoves, can solve problems such as affecting air inhalation, and achieve the effects of ensuring combustion efficiency, uniform mixing, and long mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

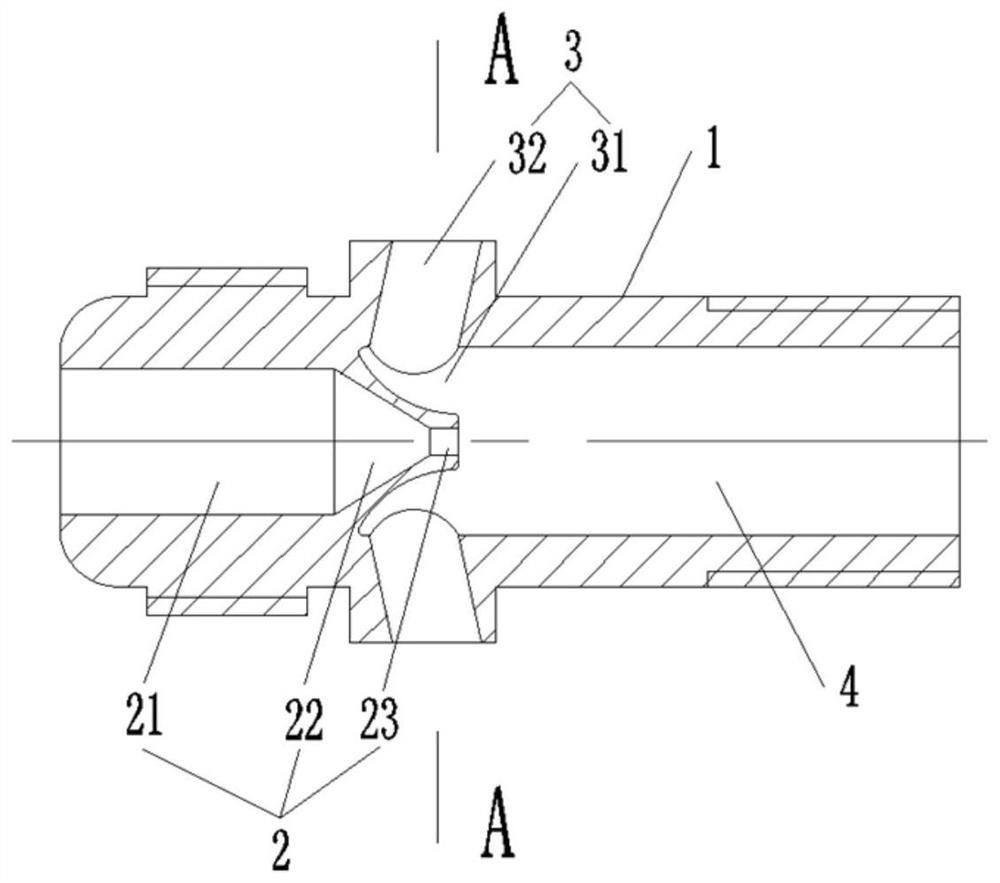

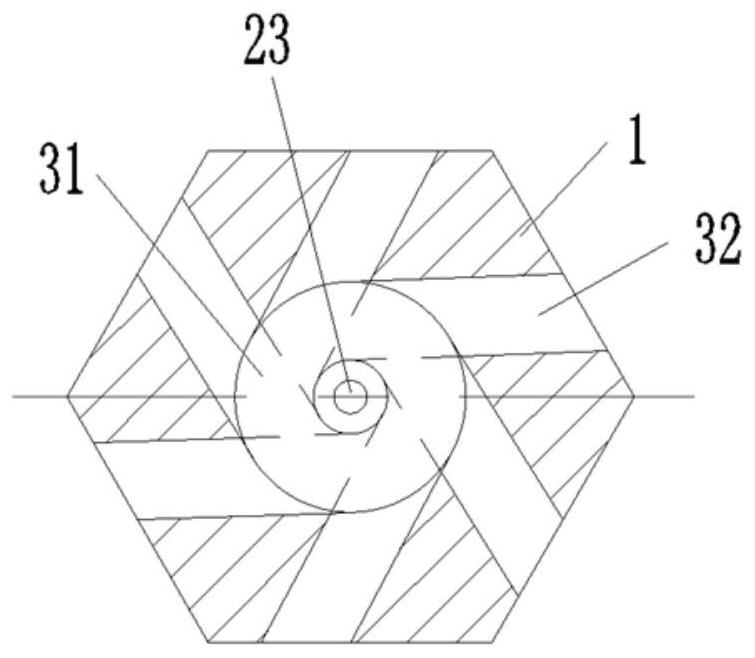

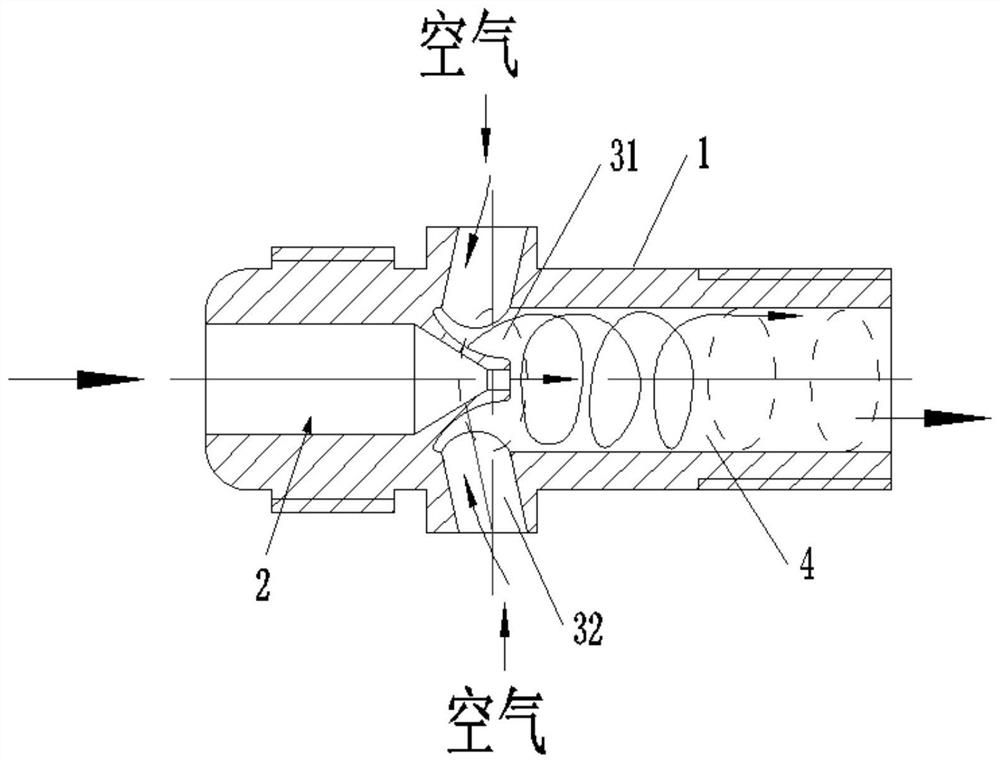

[0028] This embodiment provides a nozzle, such as Figure 1-Figure 2 As shown, it is used for a gas cooker, including a nozzle body 1, a gas inlet section 2, an air inlet section 3 and a mixing section 4; the gas inlet section 2 and the mixing section 4 are respectively arranged on the nozzle body 1 along the axial direction Both ends of the interior are connected, and the air inlet section 3 is arranged on the circumferential surface of the nozzle body 1 and communicated with the mixing section 4, so that the air enters according to the air inlet direction tangential to the circumference of the nozzle body 1;

[0029] The air forms a vortex through the air inlet section 3 , and advances to the mixing section 4 in a helical rotation to mix with the gas entering through the gas inlet section 2 .

[0030] Specifically, the nozzle body 1 is an existing prism structure, the gas inlet section 2 and the mixing section 4 are respectively arranged at both ends of the nozzle body 1 alo...

Embodiment 2

[0055] This embodiment provides a gas stove using the nozzle of Embodiment 1.

[0056] In a specific implementation, the gas stove has a burner, and the end of the nozzle body 1 close to the mixing section 4 is connected to the burner.

[0057] The gas cooker of this embodiment is provided with the above-mentioned nozzle, and the gas inlet section and the mixing section connected to each other are arranged at the two axial ends of the nozzle body, and the air inlet section connected with the mixing section is arranged along the circumferential surface of the nozzle body, so that the outside air It enters in a direction tangential to the circumference of the nozzle body, and passes through the air inlet section to form a rotating air flow, that is, a vortex. The vortex rotates in a helical line in the mixing section and mixes with the gas entering through the gas inlet section. The mixing path is a spiral Ascending type, long mixing time, more uniform and thorough mixing, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com