Self-calibration combined type water level gauge

A water level meter, combined technology, applied in the field of water level meter, can solve the problem of large error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

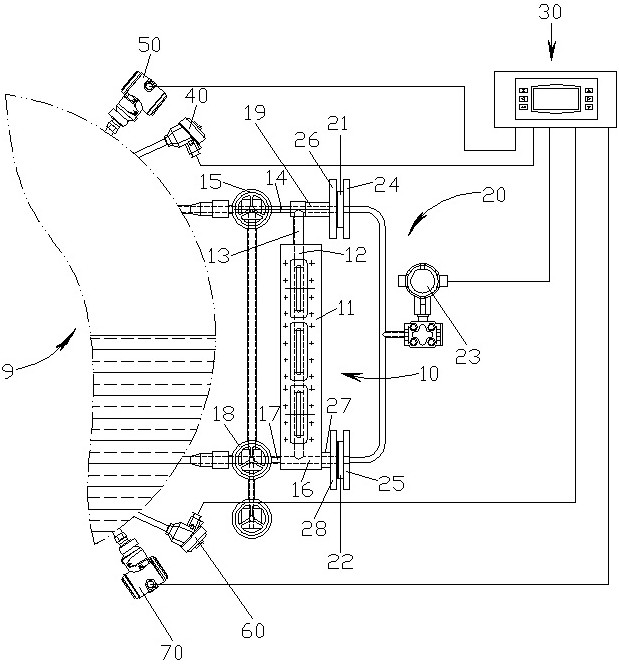

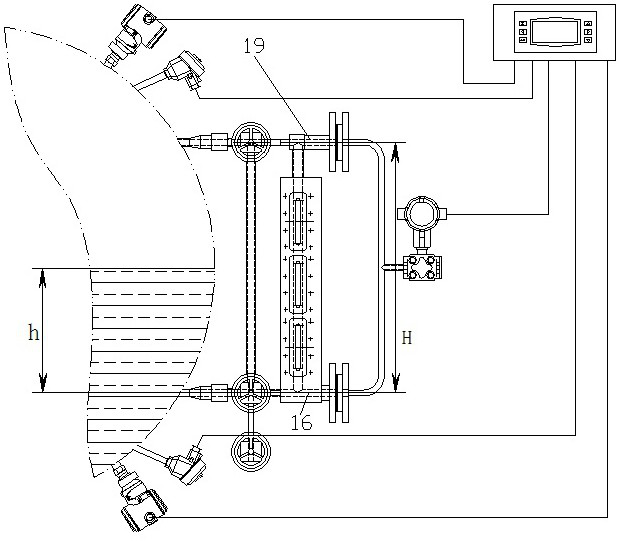

[0010] see figure 1 , a self-calibrating combined water level gauge of the present invention is used to measure the water level of the boiler drum 9, comprising a two-color water level gauge 10, the two-color water level gauge includes a water level gauge body 11, a vertical liquid channel 12 is arranged in the water level gauge body, and the water level The top of the gauge body is equipped with a vertical short pipe 13 communicating with the liquid channel, and the top of the vertical short pipe is connected with a horizontal steam side connecting pipe 14, and one end of the steam side connecting pipe is connected with a steam inlet valve 15, and the water level gauge body There is a horizontal water-side passage 16 in the lower part of the water passage 12, one side of the water-side passage is connected with a horizontal water-side connecting pipe 17, and one end of the water-side connecting pipe is equipped with a water inlet valve 18, which also includes There is a separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com