Method and device for quickly judging efficiency of new energy speed reducer

A reducer and new energy technology, which is applied in the field of automotive reducer testing equipment, can solve the problems of high cost, time-consuming sampling and inspection of the starting torque of the reducer, and the inability to timely and comprehensively monitor mass production. It achieves a unique detection method and is easy to operate. , the effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

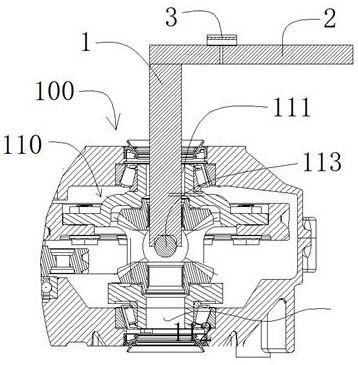

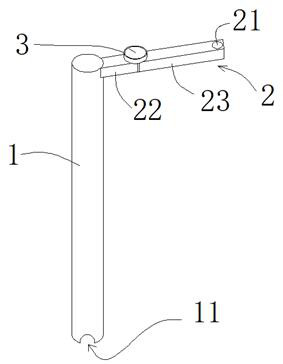

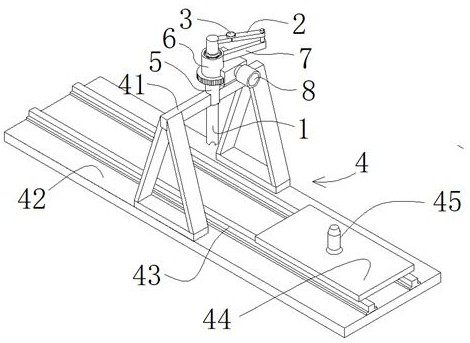

[0042] Such as figure 1 As shown in -3, a device for quickly determining the start-up efficiency of a new energy reducer designed by the above method, including a frame body 4 connecting the shaft 1, a rotating arm 2, a moment meter 3 and a uniform push arm mechanism; the frame body 4 has a seat plate 42. The lower end of the connecting shaft 1 is provided with an inverted U-shaped bayonet 11 passing through the core line of the connecting shaft 1. The inner end of the connecting shaft 1 is fixed to the rotating arm 2. The torque meter 3 is installed on the rotating arm. The push arm part of the push arm is in contact with the outer end of the connecting shaft 1; during application, the transmission is temporarily fixed on the seat plate 42 of the frame body, and the connecting shaft 1 extends into the half shaft hole 111 of the differential, and is horizontally arranged on the differential The planetary gear shaft 113 in the casing is stuck in the bayonet socket 11 of the hal...

Embodiment 2

[0050] Such as Figure 5 As shown, a device for quickly determining the start-up efficiency of a new energy reducer is different from Embodiment 1 in that the uniform-speed arm push mechanism is an active push arm mechanism, which includes a beam 41, and is arranged on the beam 41. The circular track 9 on the top, the driving wheel 10 arranged at the outer end of the rotating arm 2, and the reduction motor 8 combined with the driving wheel 10 at the outer end of the rotating arm 2; the driving wheel 10 walks on the annular track 9. When the reduction motor 8 rotates, the driving wheel 10 is driven to walk on the circular track 9 . When the power supply voltage and current of the geared motor 8 are stable, the geared motor 8 can rotate at a constant speed. Such setting is exactly that the outer end of the pivoting arm 2 walks on the circular track 9 voluntarily.

[0051] The inner circumference of the annular track 9 has inner gear teeth, and the driving wheel 10 has outer ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com