Special optical fiber guide mold for skeleton groove optical cable

A guiding mold and optical fiber guiding technology, which is applied in the field of optical cable production equipment, can solve the problems that small skeleton optical cables are of little significance and affect production efficiency, and achieve the effect of stable and reliable optical fiber arrangement and greatly increased efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

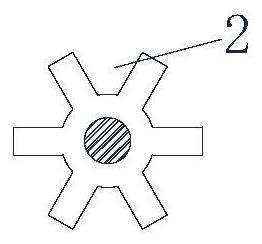

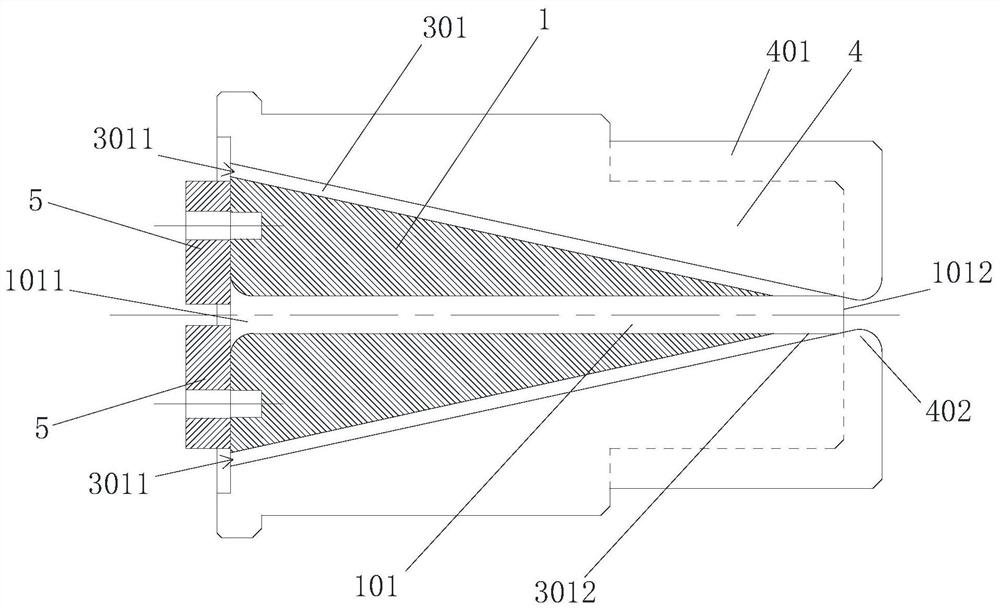

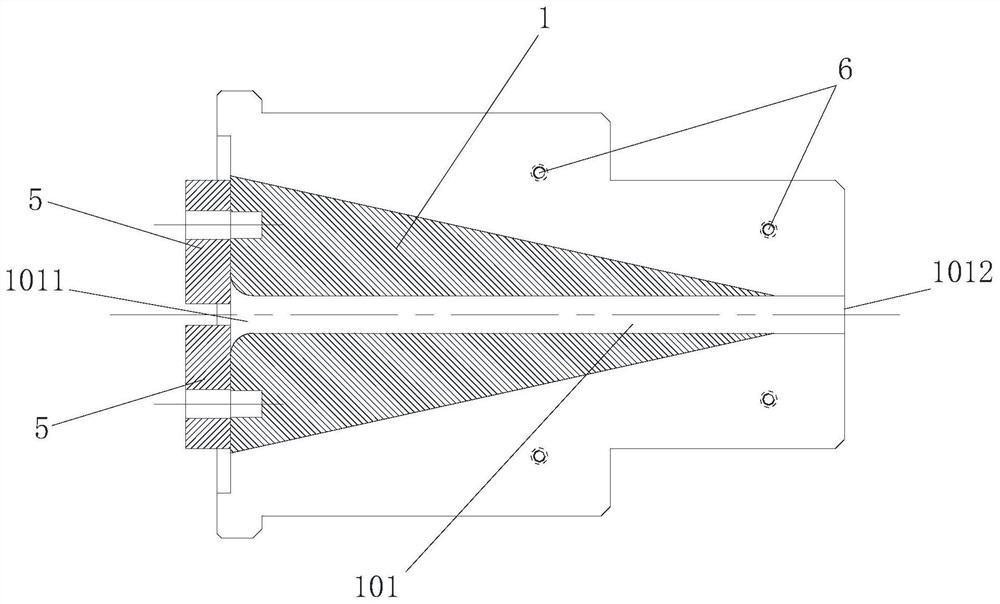

[0029] figure 2 Shown is a special optical fiber guide mold for skeleton groove optical cable, which can guide the optical fiber row to be set in the skeleton groove 2 of the skeleton, and the skeleton is evenly distributed along the circumferential direction with a number of skeleton grooves 2 extending linearly in the axial direction, such as figure 1 As shown; the fiber guide mold includes a mold main body 1, two skeleton limiters 5 and two fiber guide structures; the center of the mold main body is provided with a skeleton guide hole 101 that runs through the front and back, and the skeleton can be accommodated from the The skeleton wire inlet 1011 at the rear end of the skeleton guide hole enters and passes through the skeleton wire outlet 1012 at the front end.

[0030] Such as image 3 , Figure 4 As shown, the overall structure of the mold b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com