A positive low temperature curable photosensitive resin composition

A photosensitive resin, curing-type technology, applied in optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc., can solve the problems of unusable, unable to form organic insulating film, flexible substrate damage, etc., to achieve low Effect of temperature process, excellent moisture resistance and flexibility, excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

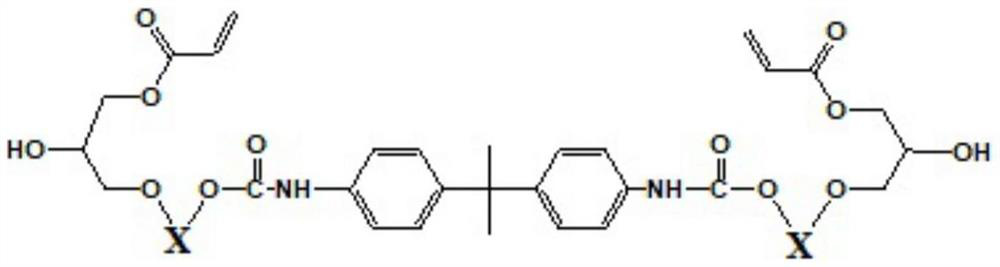

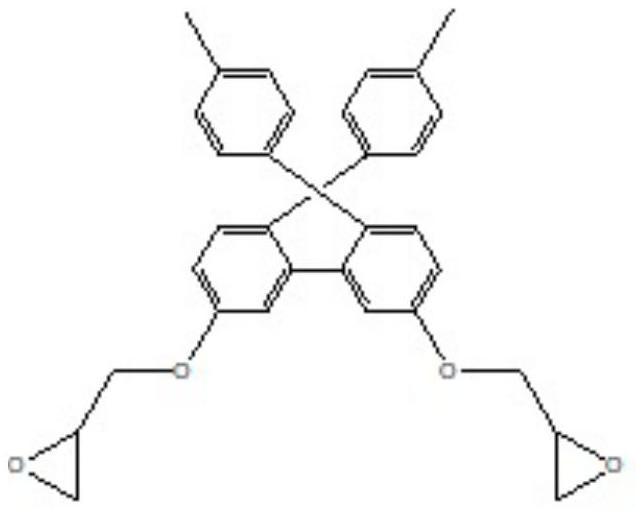

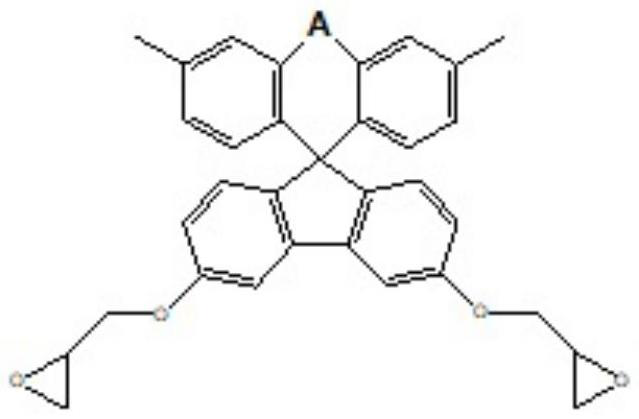

[0110] After preparing a flask equipped with a mechanical stirrer, a thermometer, and a cooling jacket, 240 g of propylene glycol monomethyl ether and 100 g of bisphenol fluorene represented by Chemical Formula 1-1 were added under a nitrogen stream, and heated to 40° C. while stirring. After adding 0.288 g of dibutyltin dilaurate to the reaction liquid, the temperature of the reactor was raised to 65°C. While continuing to stir the reaction solution, 36.98 g of 4,4'-diphenylmethane diisocyanate was slowly added separately, and the absorption spectrum of the isocyanate group (2280 cm -1 ) disappeared, and 315.2 g of epichlorohydrin was added to the reaction liquid, followed by heating to 100° C. and stirring for 1 hour. To this reaction liquid, 33.8 g of methacrylic acid was added, and the temperature was raised to 110° C. to make it react for 3 hours. Thereafter, it was dissolved in tetrahydrofuran (THF), and after obtaining a precipitate with water, it was dissolved in dich...

Synthetic example 2

[0112] After preparing a flask equipped with a mechanical stirrer, a thermometer, and a cooling jacket, 240 g of propylene glycol monomethyl ether and 100 g of bisphenol fluorene represented by Chemical Formula 1-1 were added under a nitrogen stream, and heated to 40° C. while stirring. After adding 0.288 g of dibutyltin dilaurate to the reaction liquid, the temperature of the reactor was raised to 65°C. While continuing to stir the reaction solution, 36.98 g of 4,4'-diphenylmethane diisocyanate was slowly added separately, and the absorption spectrum of the isocyanate group (2280 cm -1 ) disappeared, and 315.2 g of epichlorohydrin was added to the reaction liquid, followed by heating to 100° C. and stirring for 1 hour. To this reaction liquid, 33.8 g of methacrylic acid was added, and the temperature was raised to 110° C. to make it react for 3 hours. Thereafter, it was dissolved in tetrahydrofuran (THF), and after obtaining a precipitate with water, it was dissolved in dich...

Synthetic example 3

[0114] After preparing a flask equipped with a mechanical stirrer, a thermometer, and a cooling jacket, 240 g of propylene glycol monomethyl ether and 100 g of bisphenol fluorene represented by Chemical Formula 1-1 were added under a nitrogen stream, and heated to 40° C. while stirring. After adding 0.288 g of dibutyltin dilaurate to the reaction liquid, the temperature of the reactor was raised to 65°C. While continuing to stir the reaction solution, 36.98 g of 4,4'-diphenylmethane diisocyanate was slowly added separately, and the absorption spectrum of the isocyanate group (2280 cm -1 ) disappeared, and 315.2 g of epichlorohydrin was added to the reaction liquid, followed by heating to 100° C. and stirring for 1 hour. To this reaction liquid, 33.8 g of methacrylic acid was added, and the temperature was raised to 110° C. to make it react for 3 hours. Thereafter, it was dissolved in tetrahydrofuran (THF), and after obtaining a precipitate with water, it was dissolved in dich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com