Brake hydraulic pressure control device

A control device and brake hydraulic technology, applied in the direction of brakes, brake types, bicycle brakes, etc., to achieve the effect of improving disassembly and suppressing resonance phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

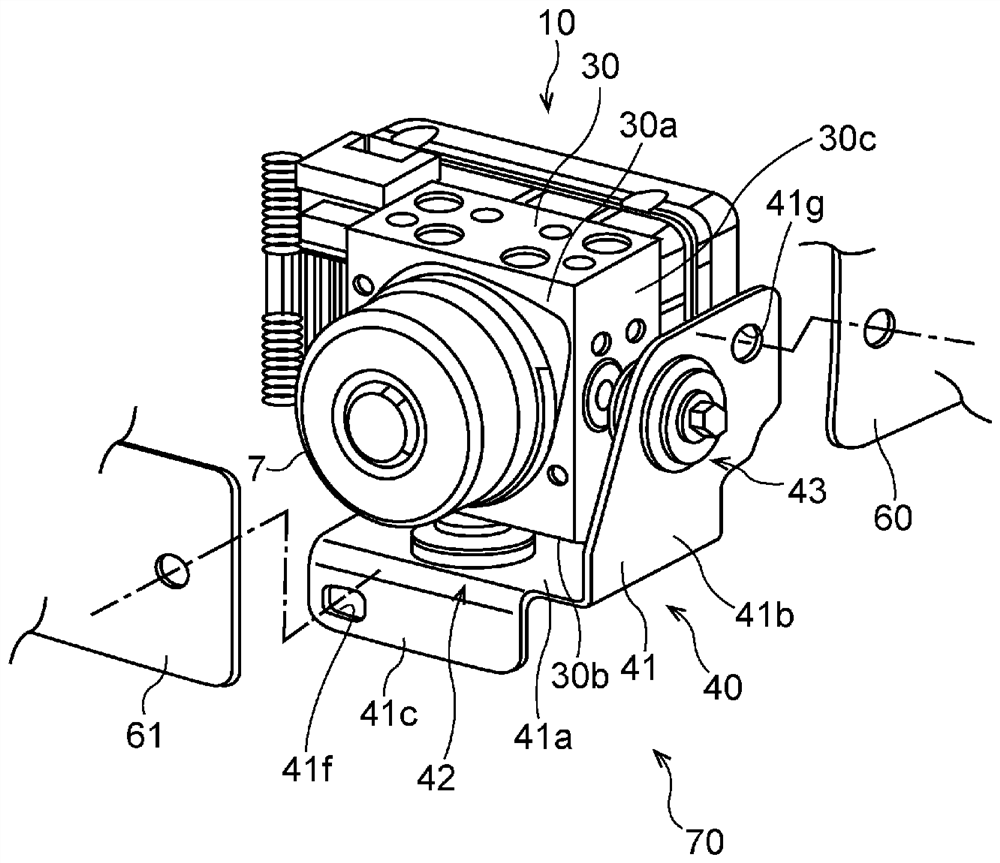

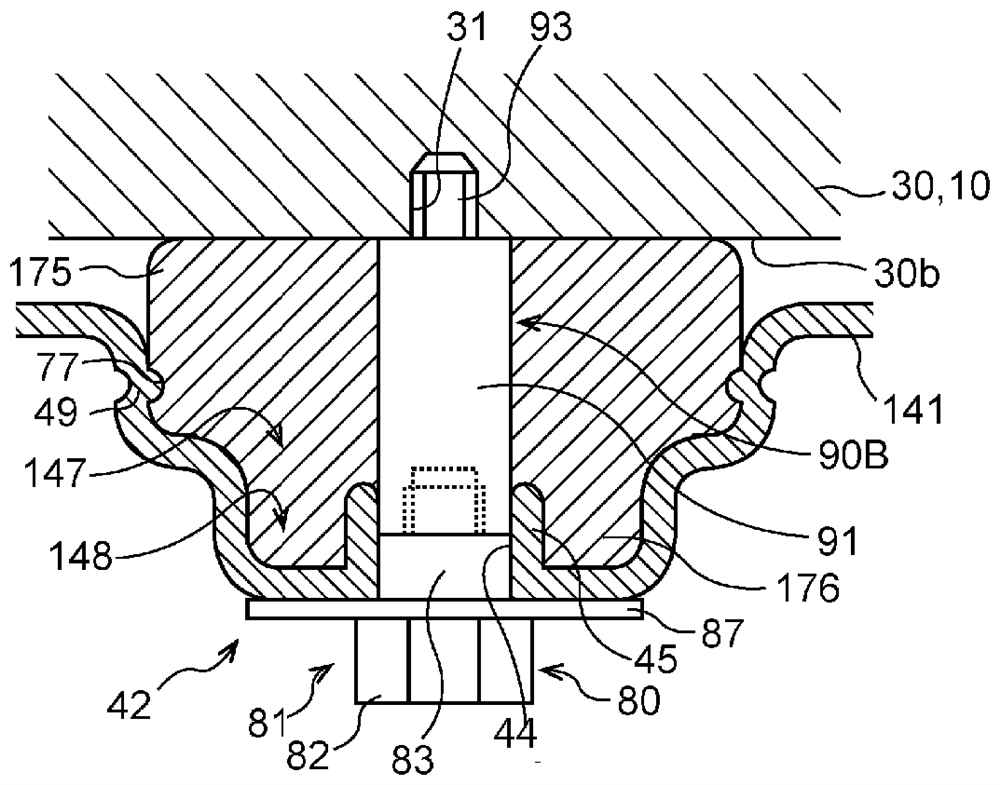

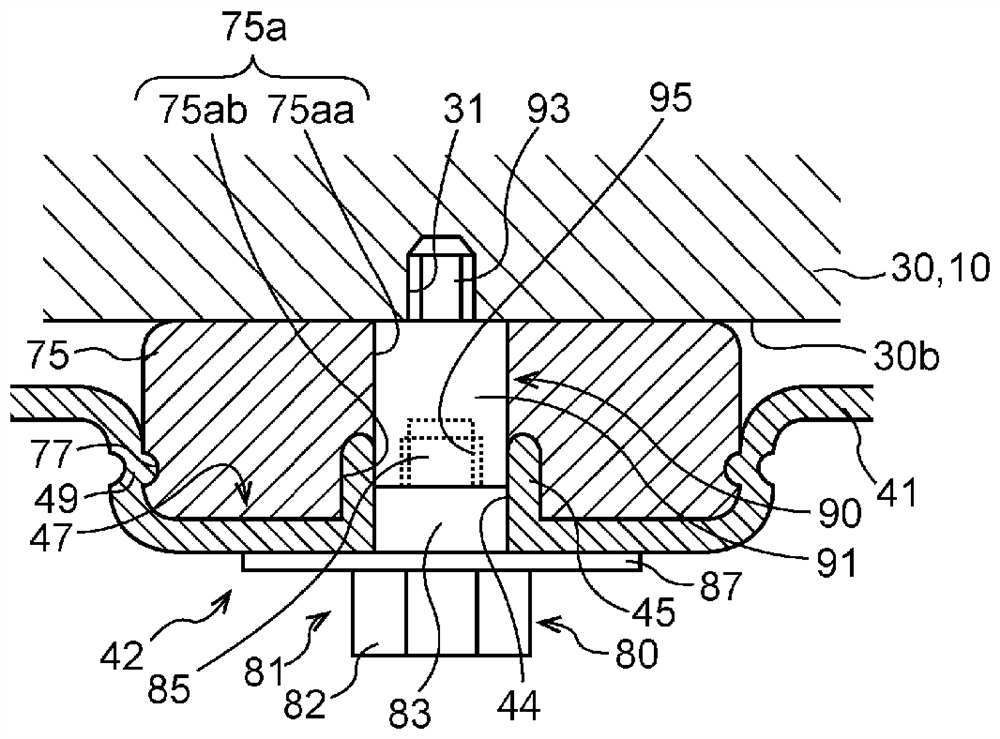

[0023] Preferred embodiments of the present invention will be described in detail below with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected about the structural element which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0024]

[0025] figure 1 An example of the brake hydraulic circuit 100 to which the brake hydraulic pressure control device 70 according to the embodiment of the present invention can be applied is shown.

[0026] figure 1 The illustrated brake hydraulic circuit 100 is mounted on, for example, a two-wheeled motorcycle, and is configured as a known hydraulic circuit for antilock brake control. Here, the anti-lock brake control (so-called ABS control) refers to control that suppresses the locked state of the wheels by intermittently reducing the brake fluid pressure during vehicle braking, for example. In addition, in the following, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com