Method and device for heating atomized liquid and preheating circuit

An atomized liquid, heated technology, applied in the application, tobacco, smoker's products and other directions, can solve the problems of difficult to control the heating of the atomized liquid, excessive heating, paste taste, etc., to avoid the problem of excessive heating, preheat uniformly, improve The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

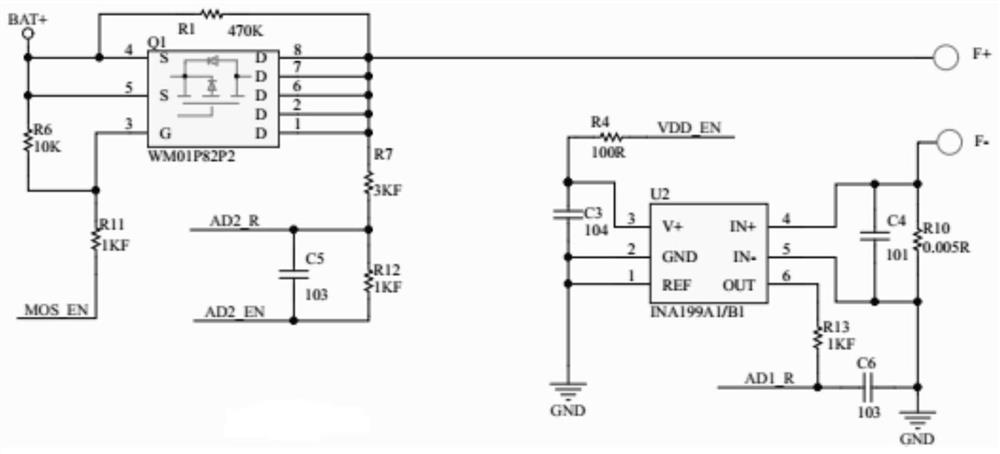

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

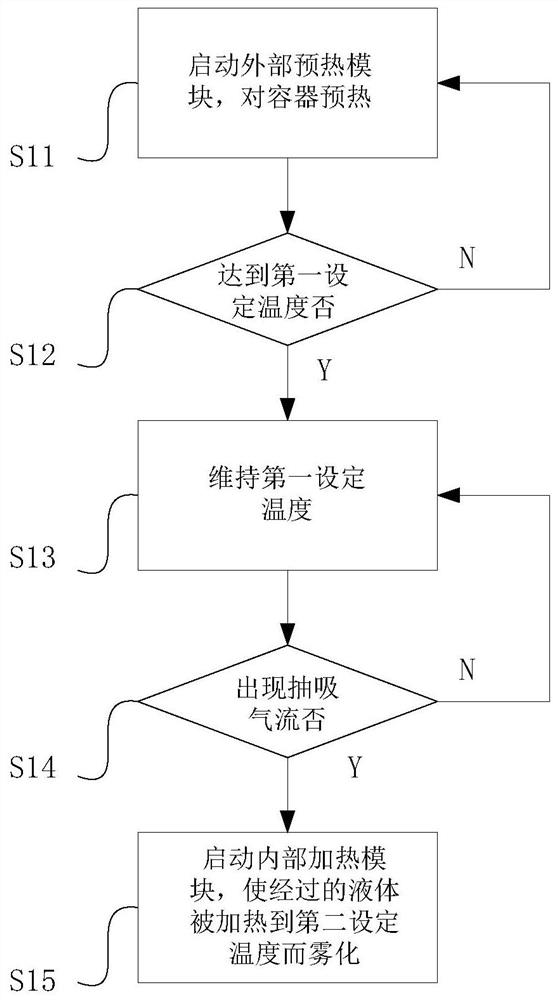

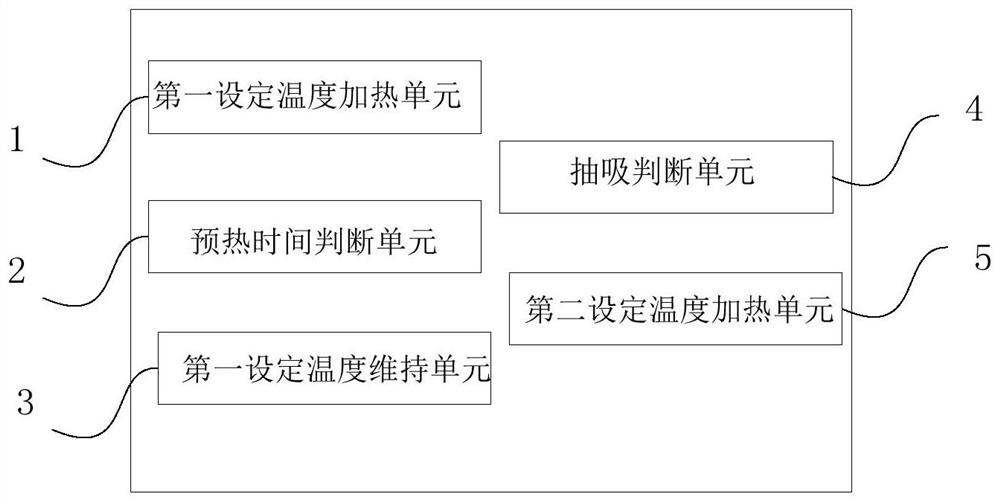

[0036] Such as figure 1 As shown, in the embodiment of the method, device and preheating circuit for heating the atomized liquid of the present invention, the method for heating the atomized liquid includes the following steps:

[0037] Step S21 Start the external preheating module to preheat the container: In this step, the microcontroller outputs a control signal to make the external preheating module start to work, preheating the container containing the atomized liquid with the first power, The purpose is to heat the container and the atomized liquid therein to a first set temperature, thereby improving the fluidity of the atomized liquid in the container, so that part of the atomized liquid can be absorbed when the suction airflow occurs. Atomization produces aerosols. In this embodiment, the above-mentioned container may be an oil cup of an atomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com