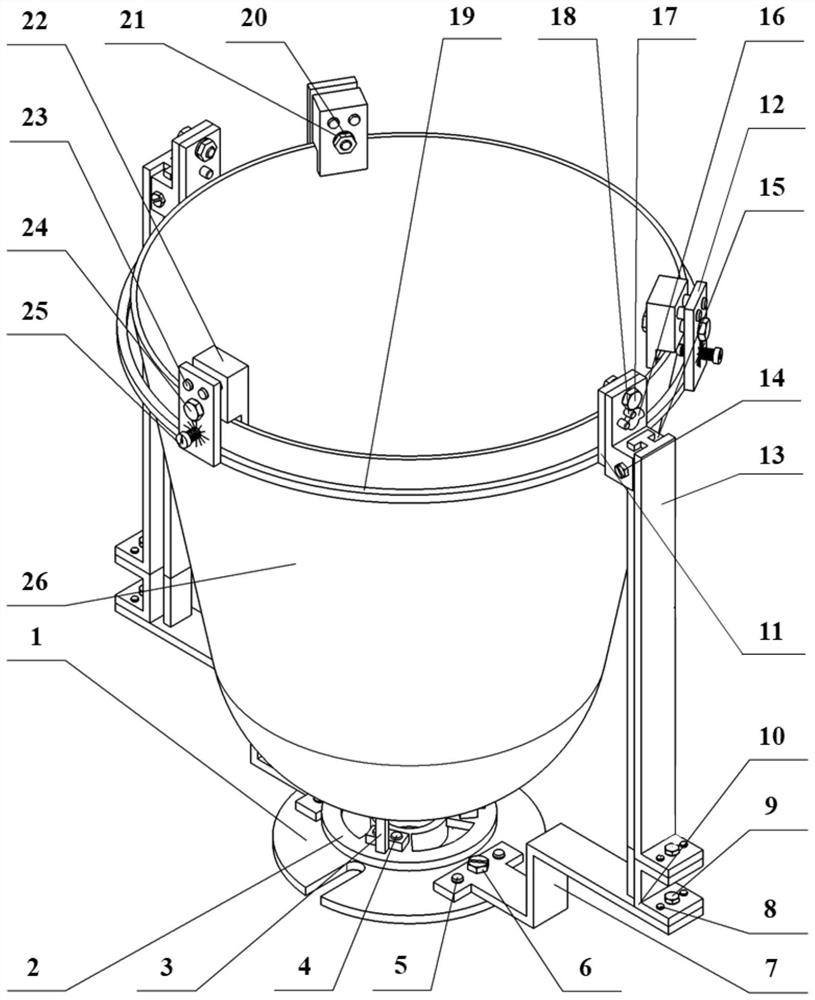

Laser processing fixture and clamping method for inner and outer walls of conical thin-walled rotary parts

A thin-wall rotary and laser processing technology, which is applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., to achieve the effects of avoiding secondary clamping, good processing accuracy, and simple body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

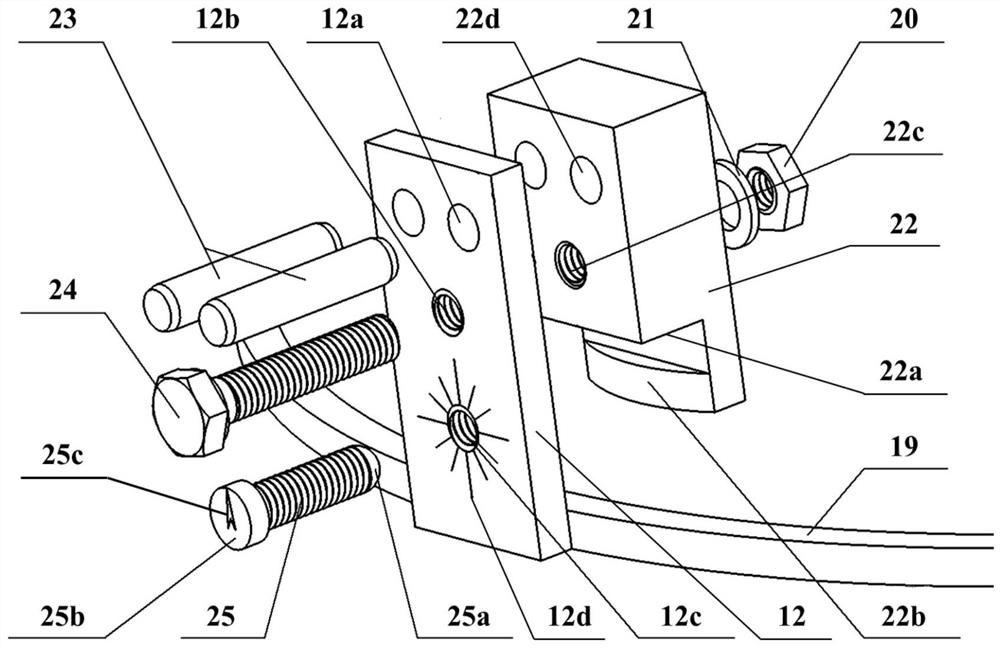

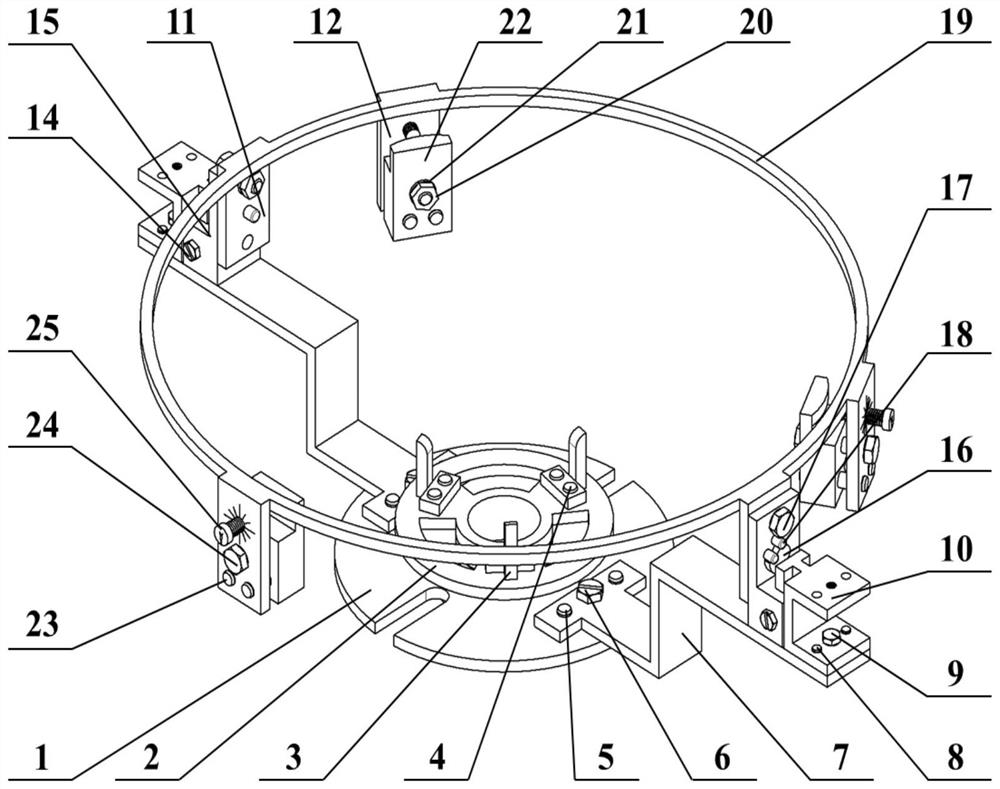

[0021] Embodiment: The special fixture and the clamping steps are as follows:

[0022]1. Install the supporting parts of the seat body

[0023] Fix the base 1 on the base of the two-axis CNC turntable with bolts and nuts, and clamp the two Z-shaped base arms 7 symmetrically on the base 1 through the positioning pin 5 and the clamping bolt 6 respectively, and then use the positioning pin 8 and the clamping The bolts 9 respectively fix the lower T-shaped guide rail 10 and the upper T-shaped guide rail 13 together, and the lower guide rail 10 is fixed on the base arm 7 through the positioning pin 8 and the clamping bolt 9 . The auxiliary support base 2 is installed on the base 1 in a threaded manner, and then the three auxiliary supports 3 are symmetrically installed on the auxiliary support base 2 by positioning two pins on one side.

[0024] The slider 15 is fixedly connected to the upper T-shaped guide rail 13 through the bolt 14, the key 27 is installed in the keyway 16c on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com