Optical axis self-power conveying mechanism

A technology of transmission mechanism and optical axis, which is used in grinding frames, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces. It can solve the problems of high energy consumption, low transmission efficiency, and high transmission equipment requirements problems, to achieve the effect of eliminating use limitations, high transmission efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

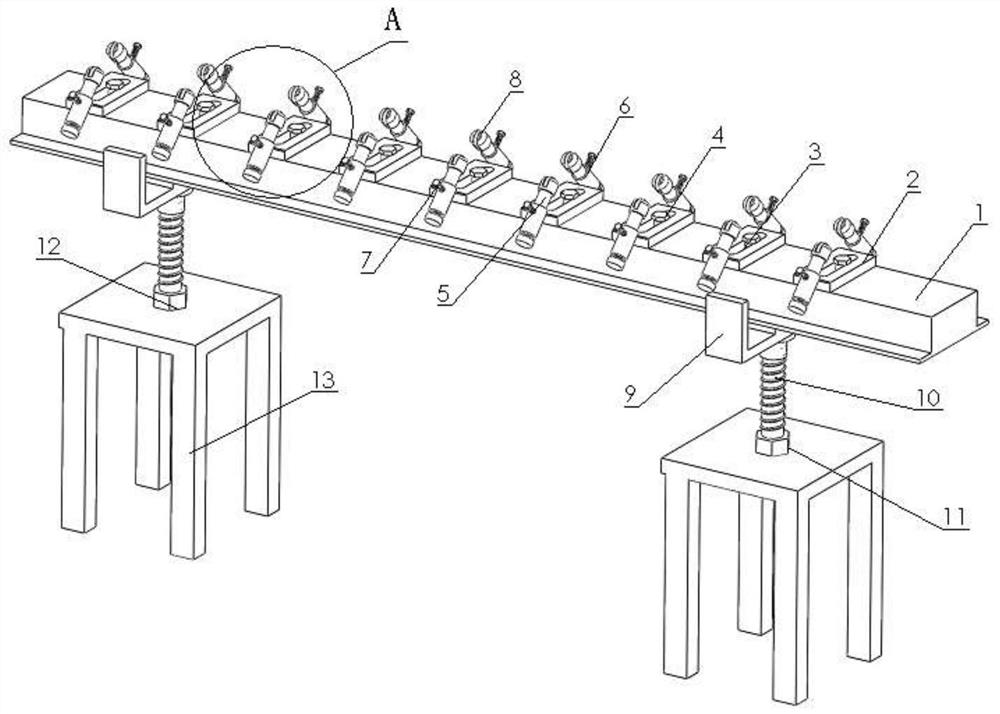

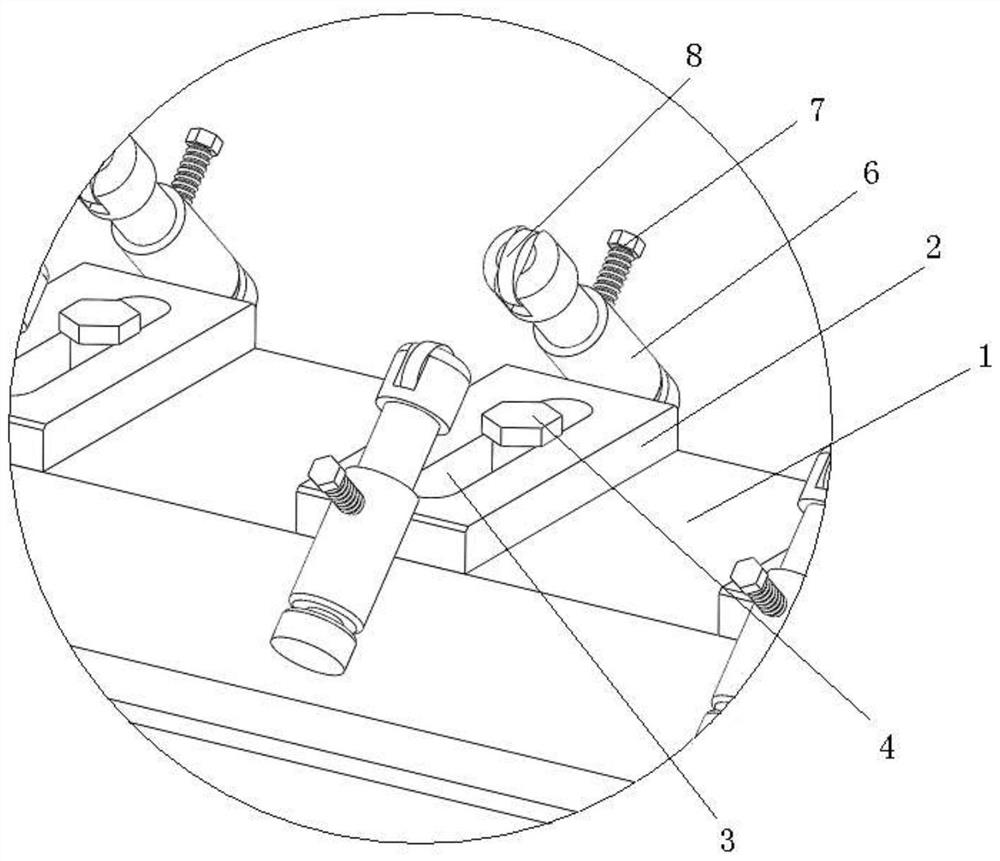

[0015] The present invention is an optical axis self-supporting transmission mechanism, which includes a transmission frame 1, a mounting base 2, a mounting groove 3, a fixing bolt 4, a left transmission column 5, a right transmission column 6, an adjustment bolt 7, a roller 8, a connecting frame 9, Supporting bolts 10, nuts 11, mounting holes 12, and supporting bases 13, the total length of the transmission frame 1 is greater than 2 meters, the transmission frame 1 is provided with mounting seats 2, and the number of mounting seats 2 is N, N≥ 8. The installation seat 2 is provided with an installation groove 3, and the installation groove 3 is provided with a fixing bolt 4, and the fixing bolt 4 passes through the installation groove 3 to fix the installation seat 2 and the transmission frame 1 together, so that The left and right transmission columns 5 and 6 are respectively arranged on the left and right sides of the mounting base 2, and the left transmission column 5 and th...

Embodiment 2

[0017] When working, one end of the mechanism is connected with the grinding machine, and the optical axis is placed on the left transmission column 5 and the right transmission column 6 of the transmission frame 1. Since there is a gap at the top of the left transmission column 5 and the right transmission column 6, the distance between the gaps is less than that of the light beam. The diameter of the shaft can ensure that the optical shaft will not fall or be clamped, resulting in the failure of transmission. Driven by the grinding mechanism of the grinding machine, the head end of the optical shaft has an initial force of rotation. The left transmission column 5, The right transmission column 6 is set in a misplaced position, which can make the optical axis move towards the grinding machine in a rotating manner. When moving, it is powered by itself and has low energy consumption. At the same time, the roller 8 is in contact with the outer periphery of the optical axis to ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com