A sealing ring cutting device

A cutting device and sealing ring technology, applied in metal processing and other directions, can solve problems such as lack of use and consumption of raw materials, and achieve the effect of avoiding waste and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

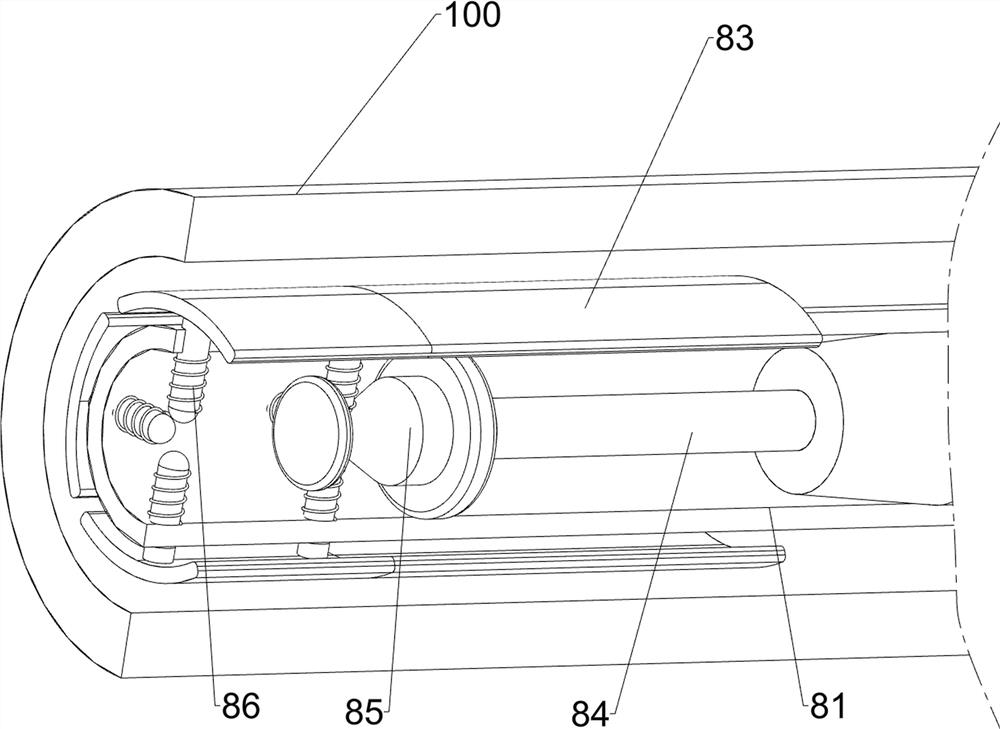

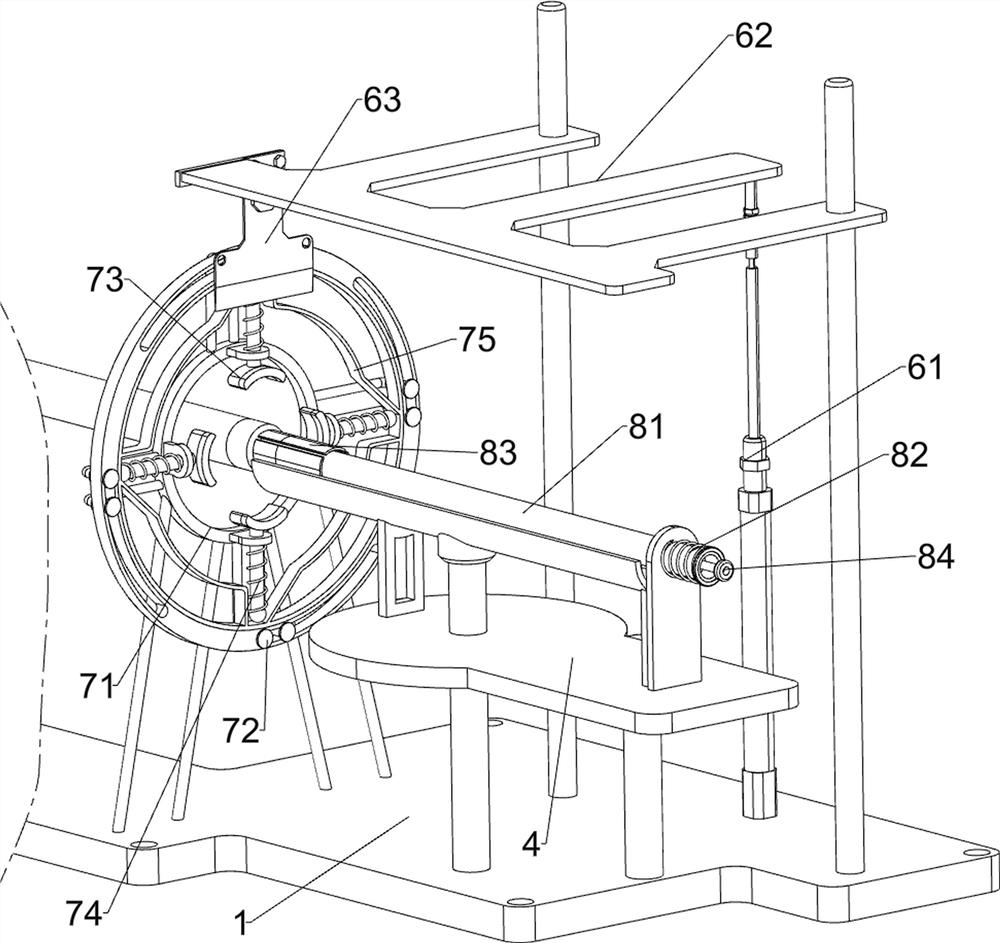

[0025] A sealing ring cutting device, such as Figure 1-3 As shown in the figure, it includes a base 1, a fixing rod 2, a connecting shaft 3, a connecting plate 4 and a placing plate 5. The top left side of the base 1 is connected with a fixing rod 2, and the right side of the top of the base 1 is rotatably connected with a connecting shaft 3 , the connecting shaft 3 is connected with a connecting plate 4, the top of the connecting shaft 3 is connected with a placing plate 5, and also includes a lifting and cutting assembly 6, a clamping assembly 7 and a pushing assembly 8, and the base 1 is provided with a lifting and cutting assembly 6 and The clamping component 7, the pushing component 8 is arranged between the placing plate 5 and the connecting plate 4.

[0026] The lifting and cutting assembly 6 includes an air cylinder 61, a sliding plate 62 and a cutting knife 63. A cylinder 61 is installed at the rear right side of the top of the base 1, a sliding plate 62 is slidably ...

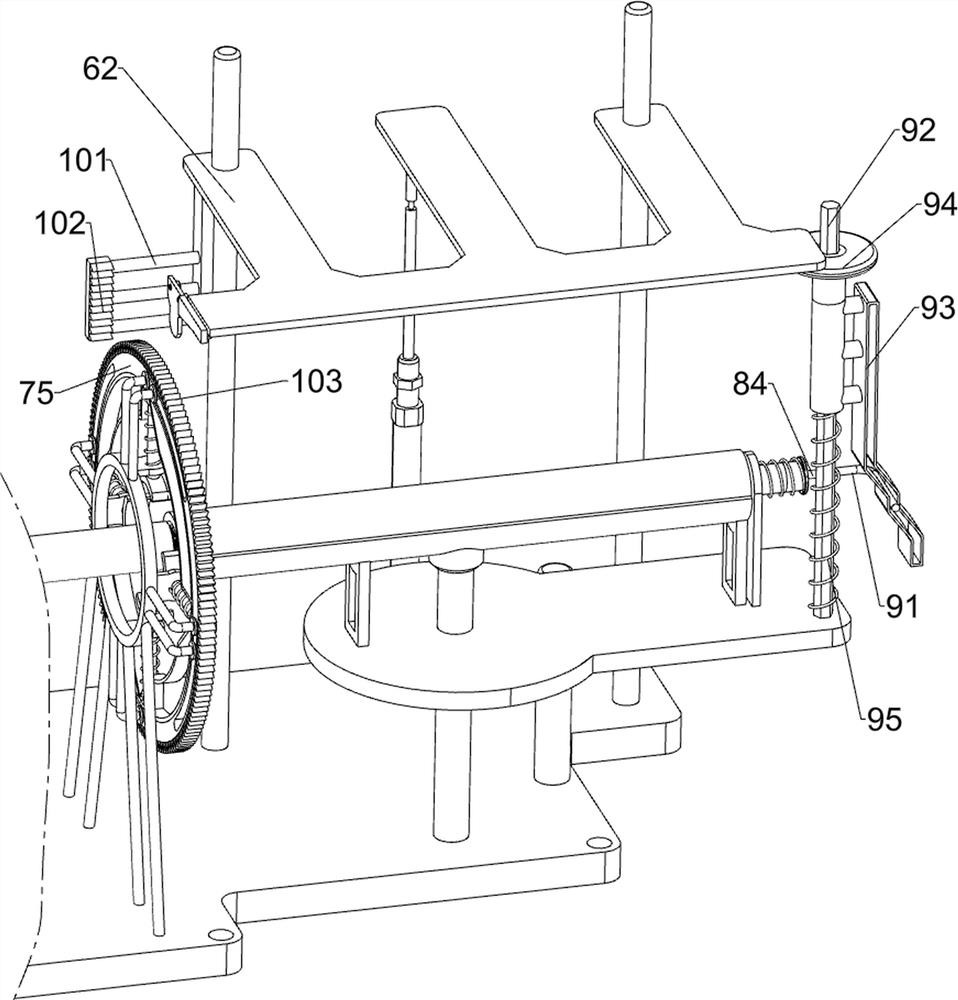

Embodiment 2

[0031] On the basis of Example 1, as Figure 4 As shown, it also includes a moving assembly 9. The moving assembly 9 includes an extension rod 91, a diamond rod 92, a guide frame 93, a connecting plate 94 and a second compression spring 95. The right side of the sliding rod 84 is connected with an extension rod 91. The connecting plate 4. A diamond-shaped rod 92 is connected to the right side of the top, and a guide frame 93 is slidably connected to the diamond-shaped rod 92. The guide frame 93 is slidingly matched with the extension rod 91. The top of the guide frame 93 is connected with a connecting plate 94. The connecting plate 94 is blocked by the bottom of the slide plate 62 , a second compression spring 95 is connected between the guide frame 93 and the connecting plate 4 .

[0032]Initially, the telescopic rod of the air cylinder 61 is in a slightly extended state, the return spring 82 is in a compressed state, and the second compression spring 95 is in a compressed st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com