Concrete stirring device for building construction

A mixing device and building construction technology, which is applied in the direction of cement mixing device, clay preparation device, cleaning method and utensils, etc., can solve the problems of increasing mixing time, reducing concrete mixing uniformity, poor mixing effect, etc., and achieve the goal of reducing maintenance and cleaning process, avoid abnormal operation, and ensure the effect of health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

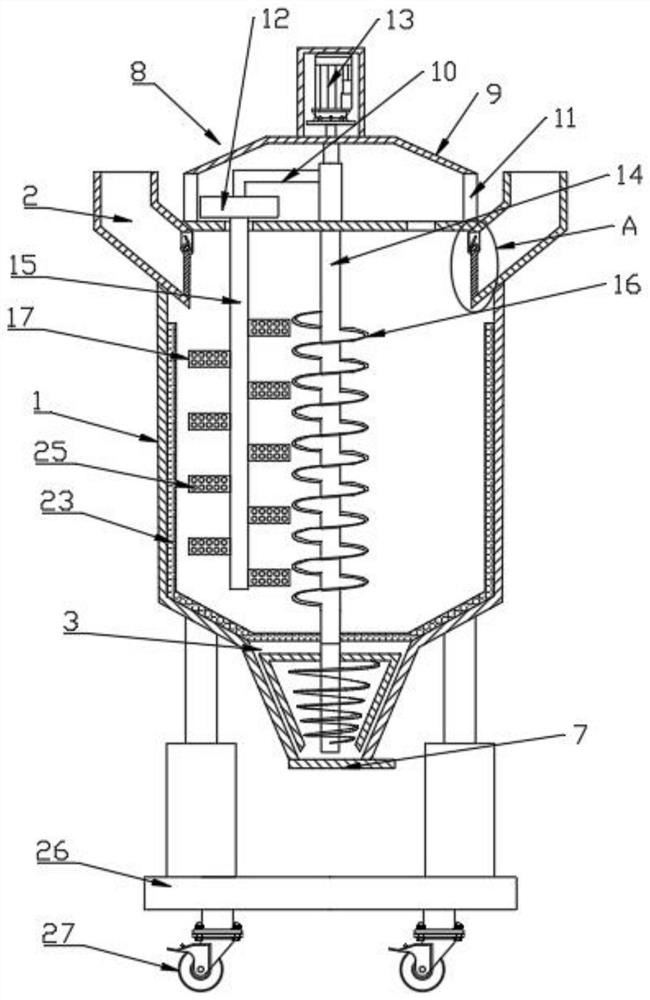

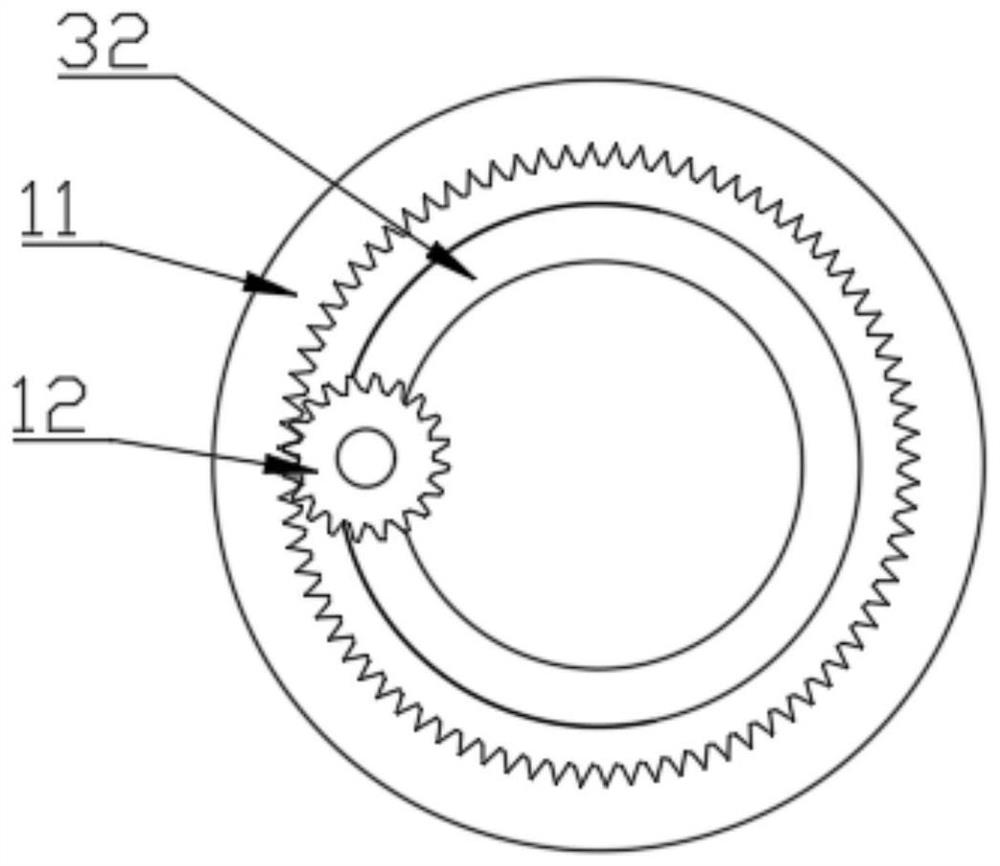

[0026] see Figure 1-5 , a concrete mixing device for building construction, comprising a mixing tank 1, the side top of the mixing tank 1 is symmetrically provided with a feed channel 2, the bottom of the mixing tank 1 is provided with supporting feet, and the center of the bottom surface of the mixing tank 1 A discharge channel 3 is provided at the bottom of the feed channel 2, an anti-splash mechanism 5 is provided at the bottom of the feed channel 2, an anti-blocking mechanism 6 is provided in the discharge channel 3, and a valve 7 is hinged at the bottom of the discharge channel 3, The top surface of the stirring tank 1 is provided with a driving mechanism 8, and the driving mechanism 8 includes a top cover 9, a deflection rod 10, a first gear 11, a second gear 12, a motor 13, a first rotating shaft 14 and a second rotating shaft 15 , the first gear 11 is fixed on the top surface of the stirring tank 1, and the first gear 11 is an internal gear, the top cover 9 is fixed o...

Embodiment 2

[0033] This embodiment has been improved on the basis of Embodiment 1, specifically:

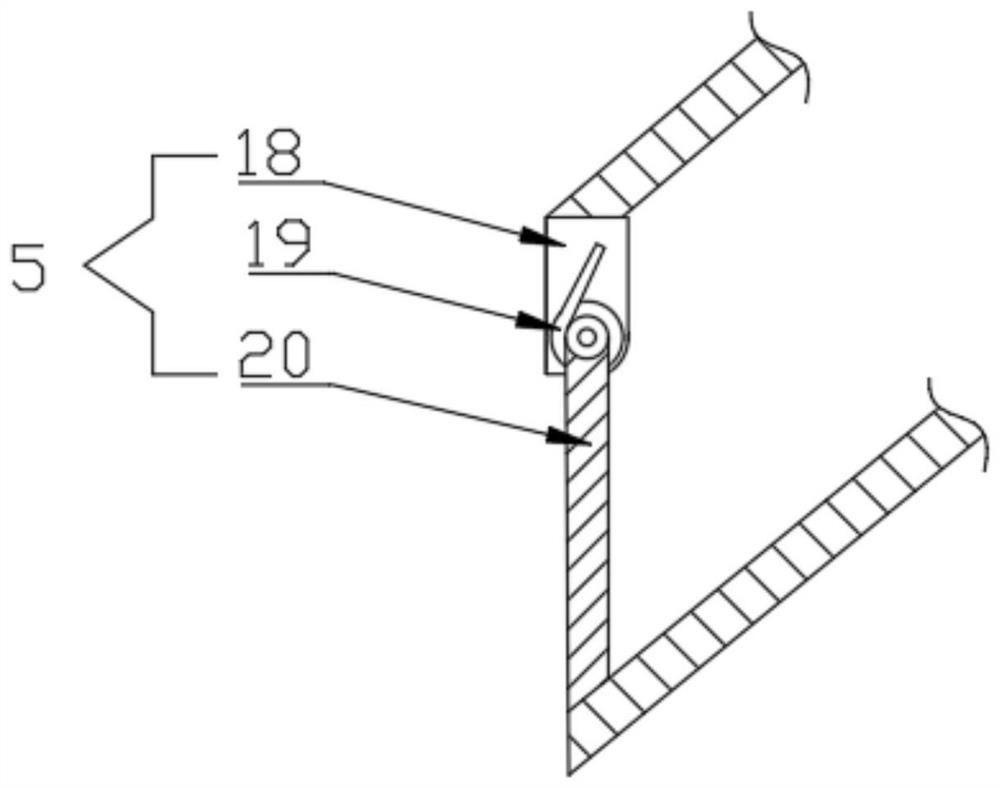

[0034]The anti-splash mechanism 5 includes a mounting base 18, a torsion spring 19 and a baffle plate 20, the mounting base 18 is fixed on the top side wall of the bottom of the feeding channel 2, and a torsion spring is movably installed on the outside of the mounting base 18 19. The outer side of the torsion spring 19 is movably equipped with a baffle 20. By setting the anti-splash mechanism 5, the concrete raw material is poured into the feed channel 2. Under the gravity of the concrete raw material, the torsion spring 19 rotates to make the baffle 20 separate, so that the raw materials enter the mixing tank 1, after the materials enter, the torsion spring 19 rotates in the opposite direction, so that the baffle plate 20 is closed again, which avoids the increase of air dust caused by the blowing of the cement by the air during the operation of the mixing device, thereby Protect the healt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com