Vertical grain solvent-free silicone oil release film

A release film, solvent-free technology, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve the problems of inability to tear directly, complicated operation, and reduced convenience, so as to improve convenience, simple operation, Improve the effect of mounting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

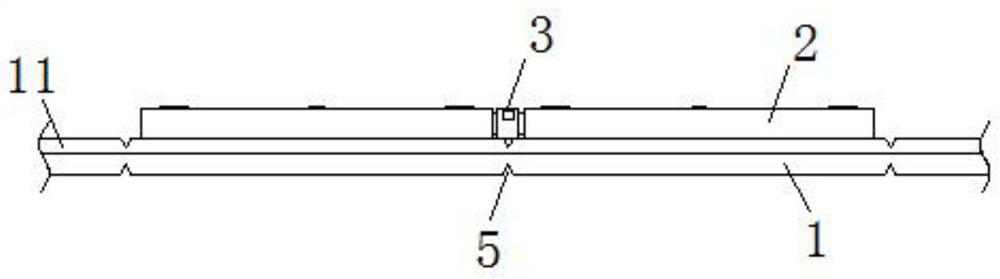

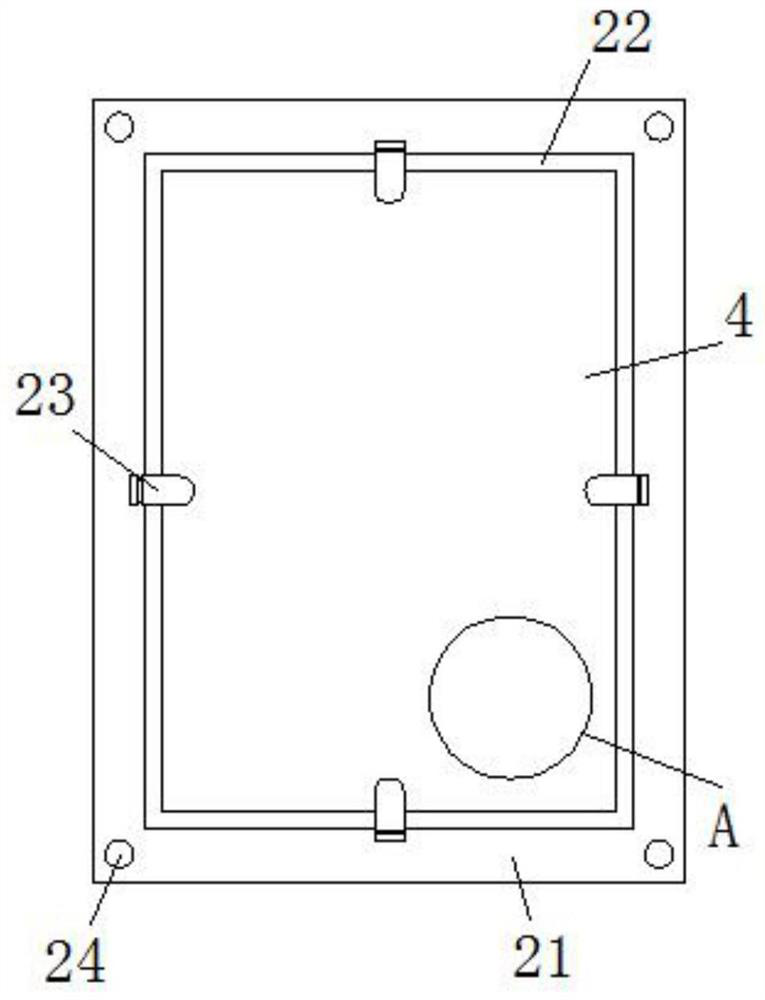

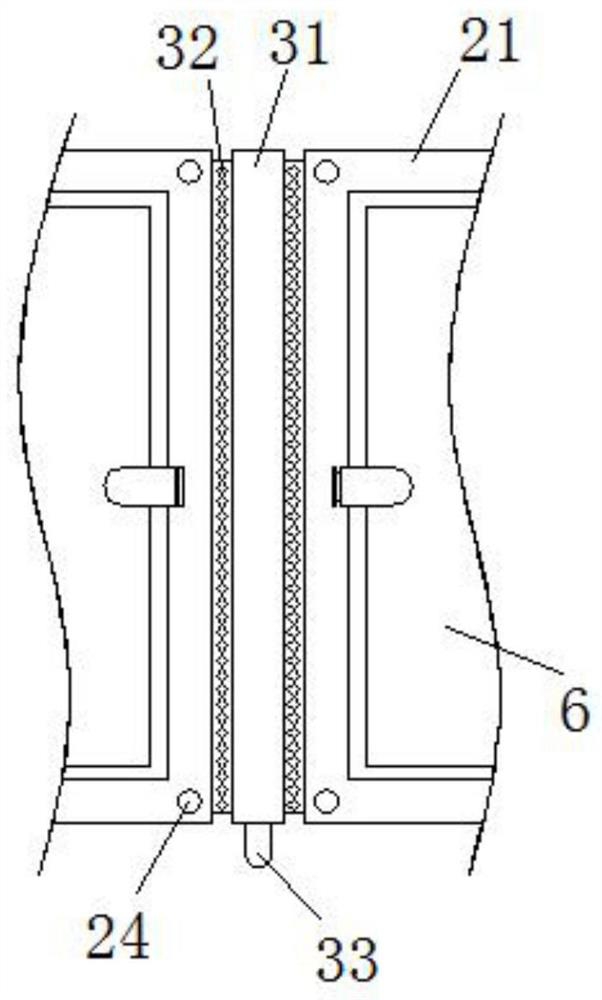

[0025] Example: such as Figure 1-5 As shown, a vertical-grain solvent-free silicone oil release film of the present invention includes a backing paper 1, and the upper surface of the backing paper 1 is fixedly bonded with two limiting mechanisms 2, and between the two limiting mechanisms 2 A connection mechanism 3 is installed together, and the connection mechanism 3 is fixedly bonded to the upper surface of the backing paper 1, a release film body 4 is provided in the two limit mechanisms 2, and the two release film bodies 4 The lower surface of the film body 4 is all attached to the upper surface of the backing paper 1, and the backing paper 1 is dug with a number of folding line grooves 5, and the several folding line grooves 5 are all located below the matching connecting mechanism 3 , when the release film body 4 is in use, there is no need to use scissors to cut it, it can be easily torn, the operation is simple, and the convenience of its use is greatly improved. Alig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com