A multi-functional propulsion mechanism of an underwater inspection robot for a cable pipe gallery

A technology for inspection robots and propulsion mechanisms, applied to underwater ships, underwater operating equipment, motor vehicles, etc., can solve the problems of protective layer damage, grounding, thinning, etc., and achieve transmission and control, convenient adjustment, and design ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

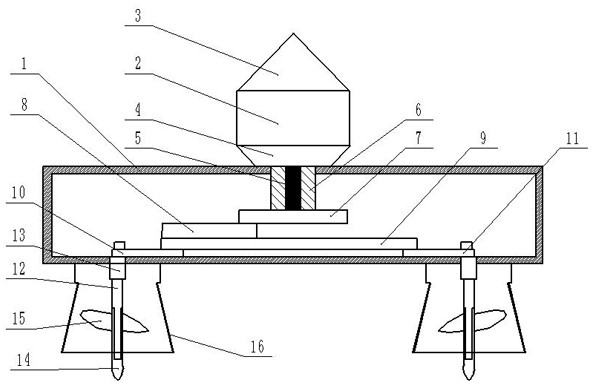

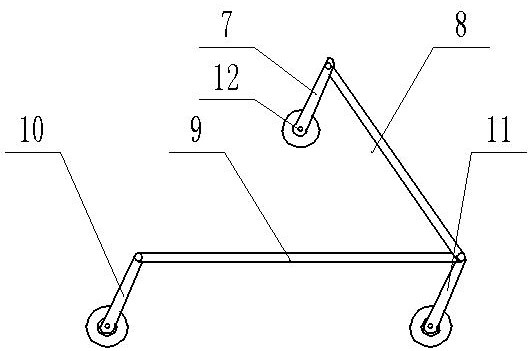

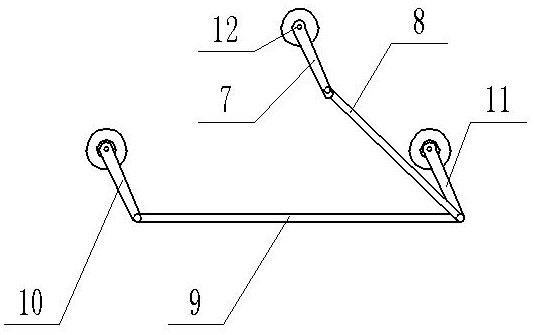

[0029] Such as figure 1 Shown is a structural schematic diagram of a multifunctional propulsion mechanism for a cable gallery underwater inspection robot provided in this implementation, which includes a hollow frame-shaped fixture 1, a power component, and two sets of propulsion components connected to the power component ; The power assembly includes an underwater motor 2, and the underwater motor 2 is connected with a control module for controlling the underwater motor through wired or wireless connection. The propulsion mechanism provided by the present invention can be fixed on the shell of the underwater inspection robot through the fixing piece 1, and can also be arranged as an integral structure with the robot.

[0030] The propulsion assembly includes a wind deflector 16, a propeller shaft 12 connected to the motor shaft 5 of the underwater motor 2 and a propeller cap 14 connected to the propeller shaft 12 are arranged in the wind deflector 16, and on the propeller sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com