Process for extracting wheat germ oil by using low-temperature subcritical method

A technology for wheat germ oil and wheat germ, which is applied in the production of fat oil/fat, refining of fat oil/fat, vegetable protein processing, etc. Excellent physical and chemical indicators, the effect of reducing oil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

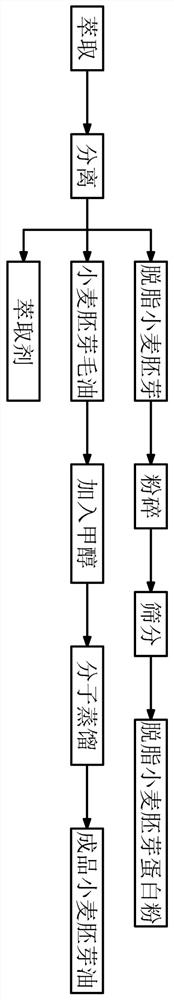

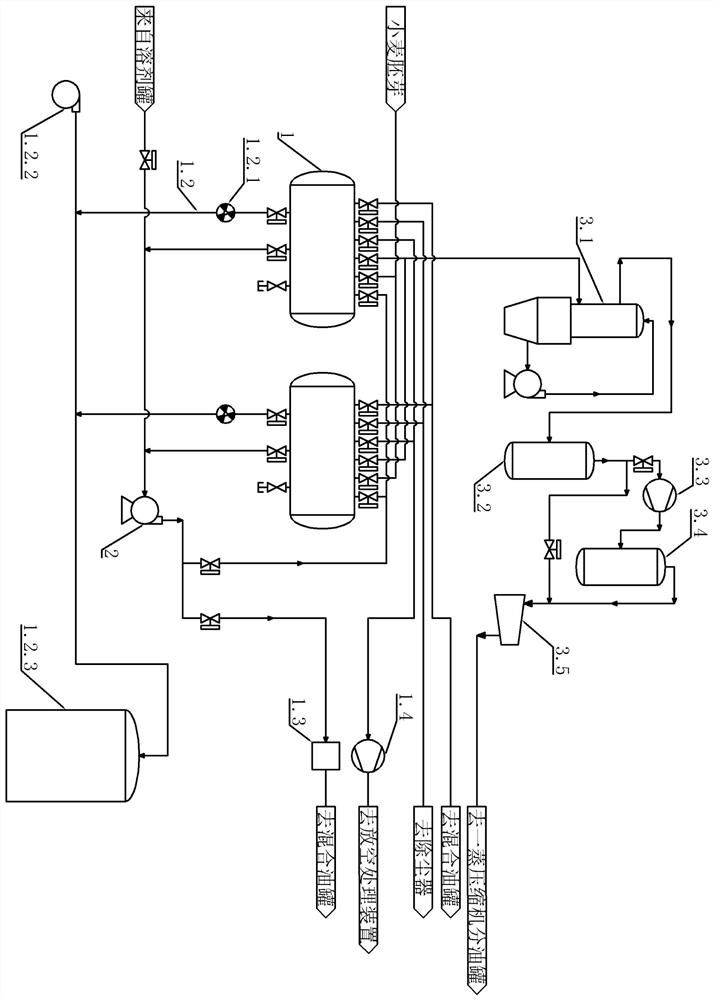

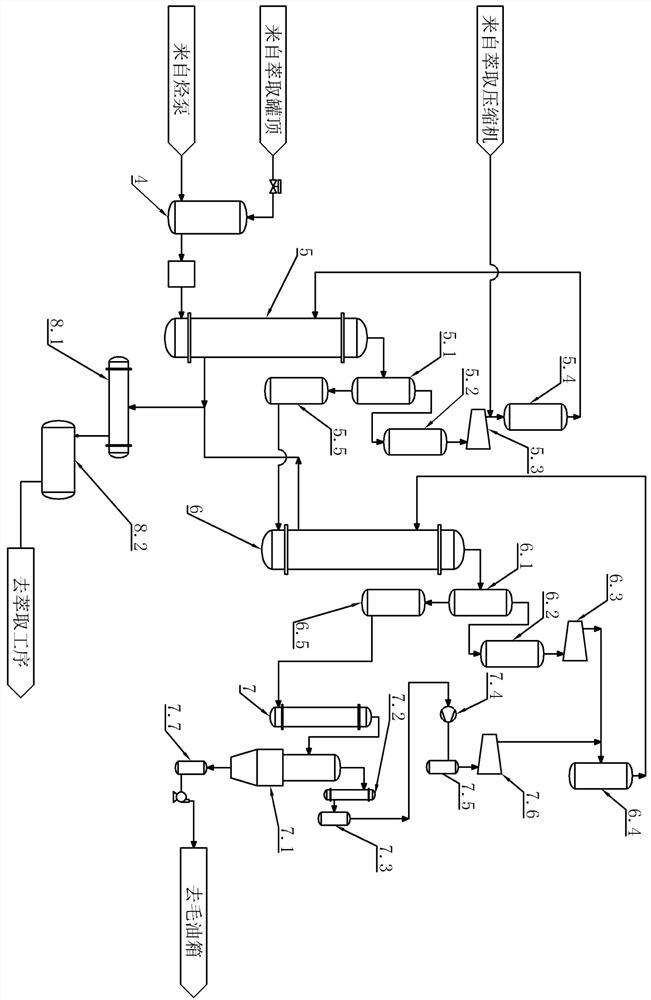

[0032] Such as Figure 1-Figure 3 Shown, a kind of low-temperature subcritical method extracts the technology of wheat germ oil, comprises the following steps:

[0033] S1. Using a solvent to extract the wheat germ to obtain a mixture of wheat germ crude oil, defatted wheat germ and solvent, and separating the defatted wheat germ;

[0034] S2. separating wheat germ crude oil and solvent from each other;

[0035] S3. Grinding and sieving the defatted wheat germ to obtain defatted wheat germ protein powder;

[0036] S4. Degumming, washing, and dehydrating the crude wheat germ oil, then using methanol as a solvent to extract and deacidify the crude wheat germ oil, then separating the crude wheat germ oil from methanol, and then molecularly distilling the crude wheat germ oil to obtain the finished product Wheat germ oil, the acid value of the finished wheat germ oil is below 0.1mgKOH / g, the peroxide value is below 1g / 100g, and the moisture content is 0.05%.

[0037] Described ...

Embodiment 2

[0054] There is no essential difference between this embodiment and Embodiment 1. The difference is that the water content of the wheat germ added to the extraction tank 1 is dried at 1%, while the acid value of the finished wheat germ oil is 0.053mgKOH / g, and the peroxide value is 0.1 g / 100g, moisture 0.04%.

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the water content of the wheat germ added to the extraction tank 1 is dried at 5%, and the acid value of the finished wheat germ oil is 0.076mgKOH / g, and the peroxide value is 0.5 g / 100g, moisture 0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com