Construction method of beam-slab tower crane foundation structure

A technology of tower crane foundation and construction method, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of not being economical, safe and reliable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

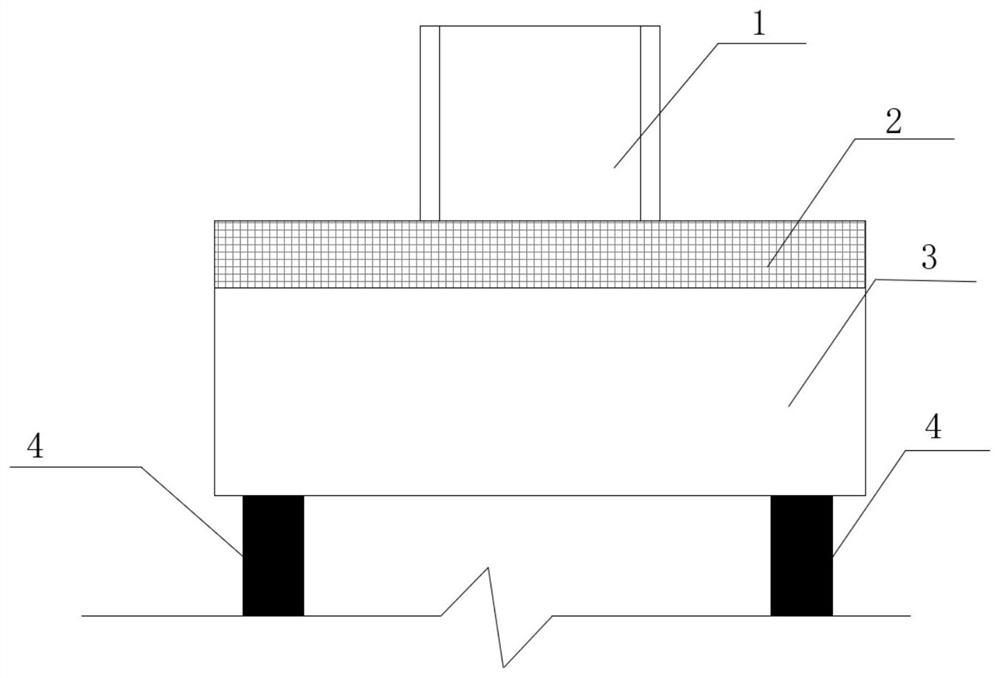

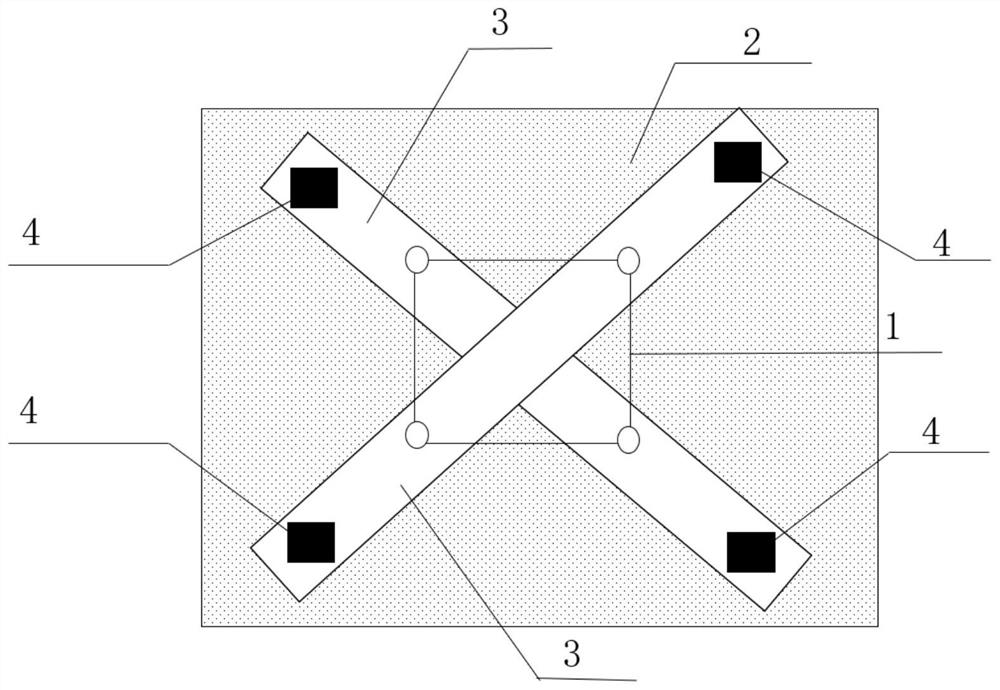

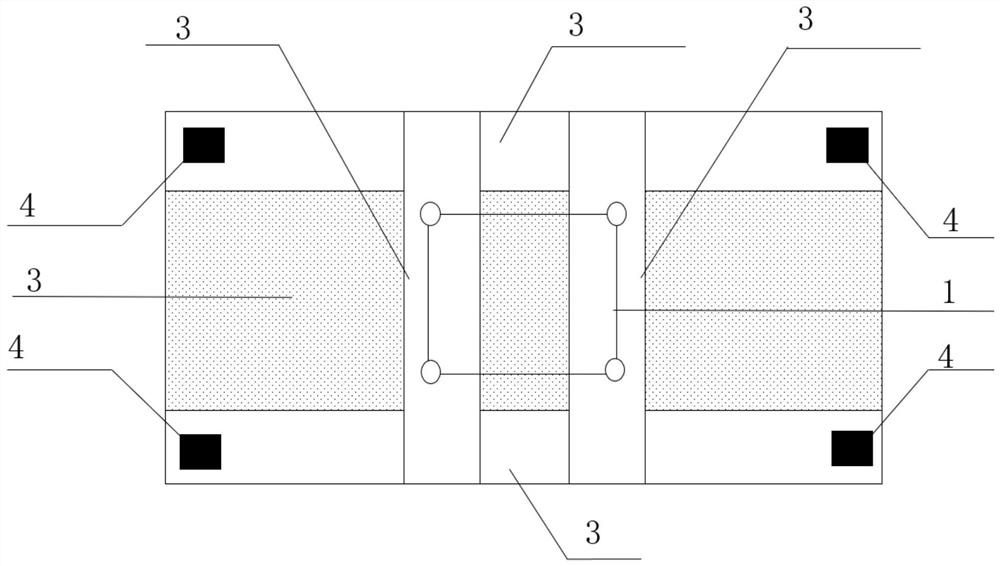

[0023] Please refer to Figure 1 to Figure 3 , this embodiment provides the construction method of the beam-slab tower crane foundation structure of the present invention.

[0024] The construction method includes:

[0025] Step S1 determines the plane position of the tower crane according to the site conditions and hoisting requirements, and constructs the supporting columns 4 in the foundation structure of the tower crane, and the supporting columns 4 are distributed in four corners.

[0026] Step S2 lays the base film of the support beam 3 above the support column 4, binds the steel bars of the support beam 3, accurately locates and installs the tower crane base 1 and its connectors according to the design requirements, and the connectors are usually high-strength bolts or foundation anchors of the tower crane.

[0027] Step S3 constructs the side form of the support beam 3, and constructs the bottom form of the cap plate 2 above the support beam 3;

[0028] Step S4 binds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com