Split type municipal well and construction method thereof

A split, municipal technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as reducing the construction speed, and achieve the effect of speeding up the construction process, ensuring the quality of the structure, and strengthening the strength of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

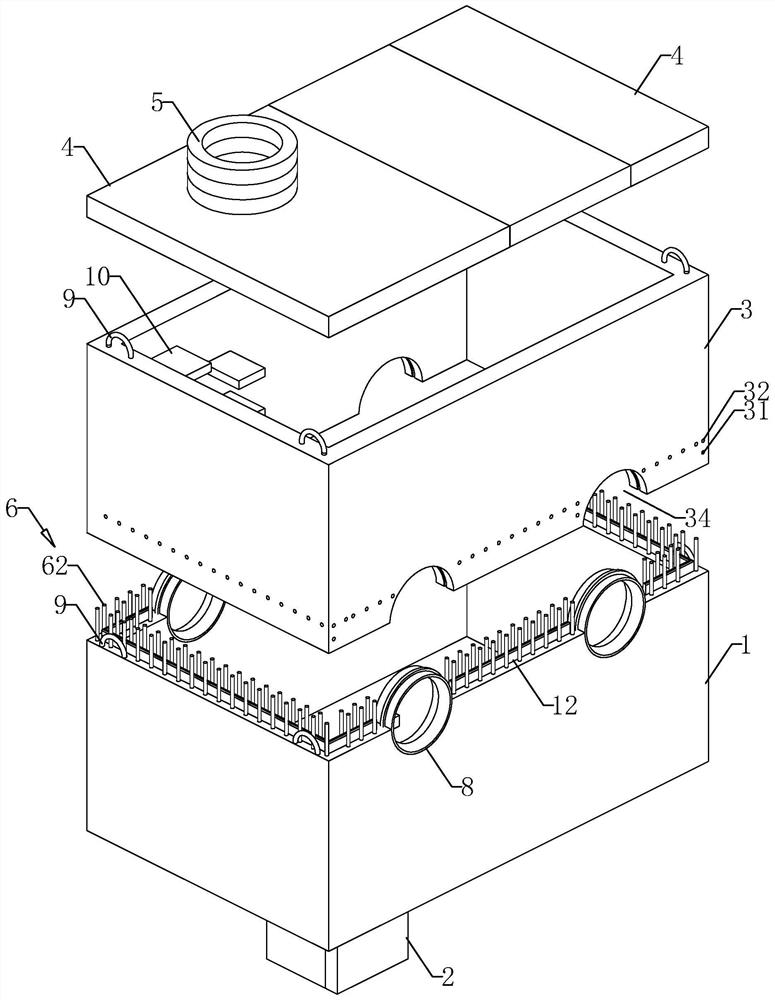

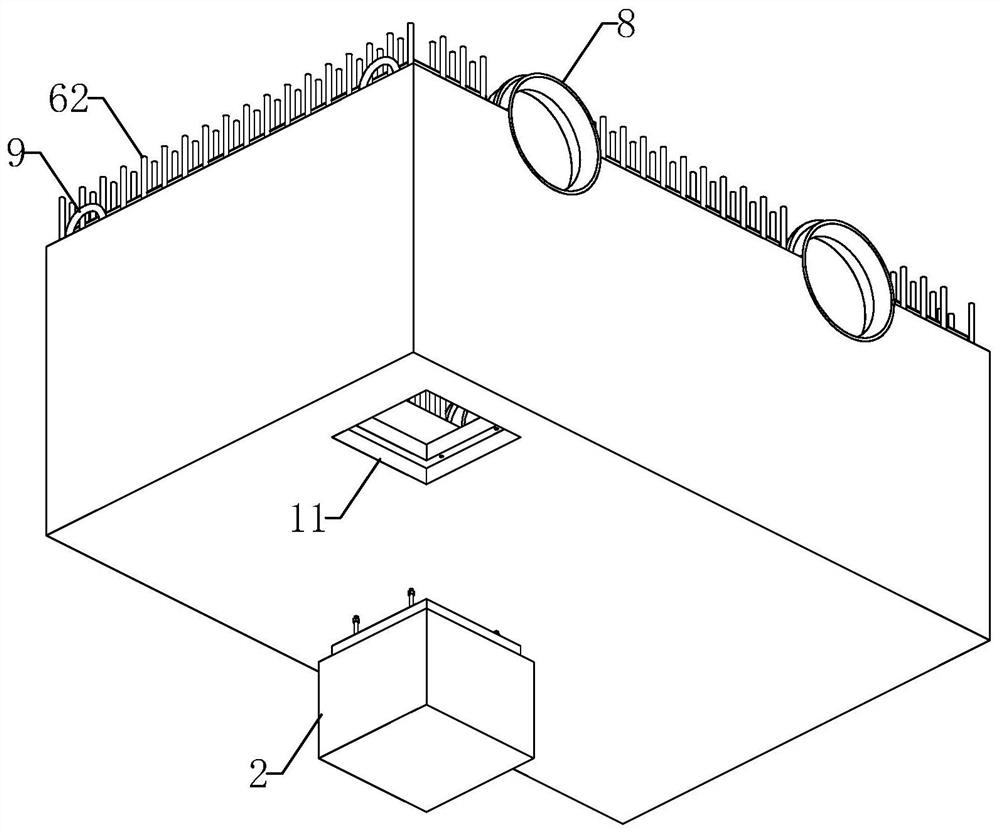

[0046] The following is attached Figure 1-7 The application is described in further detail.

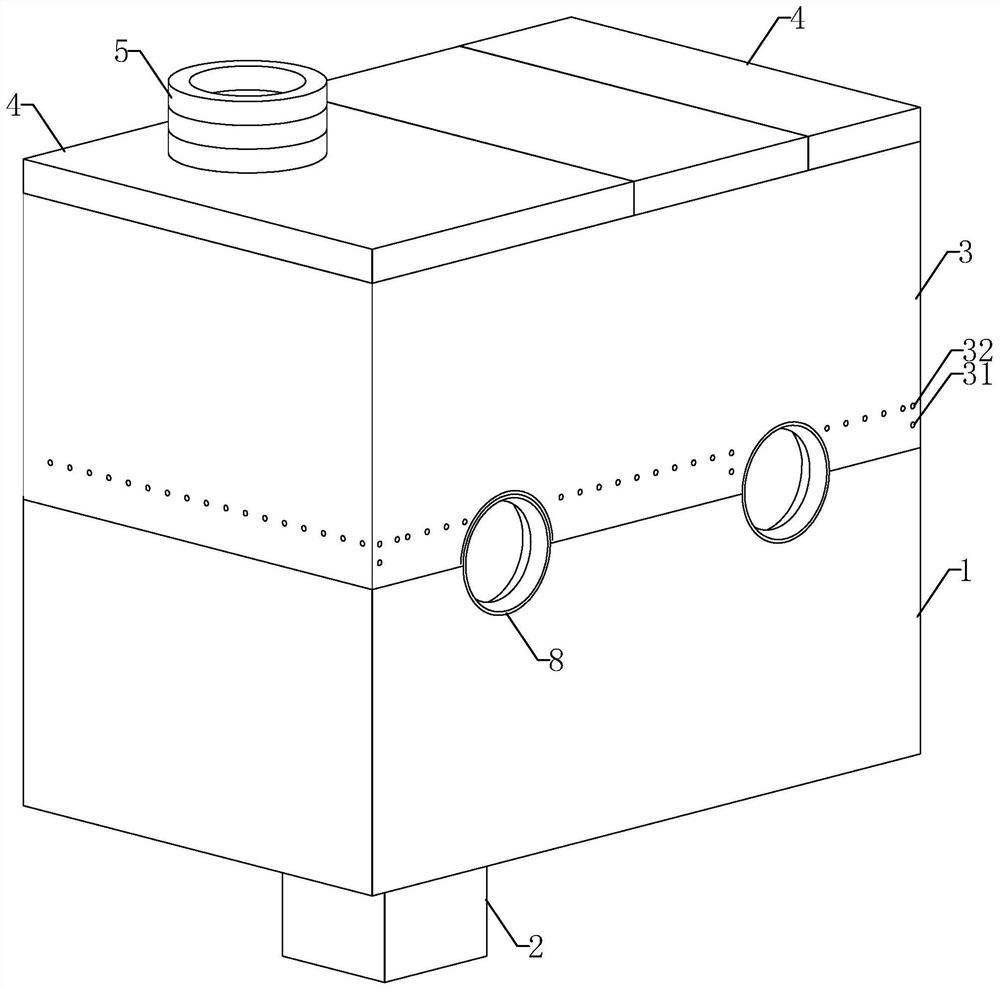

[0047] A split type municipal well disclosed by the application, combining figure 1 , figure 2 The municipal well includes a lower chamber 1 with an opening on the upper part, a sump 2 arranged at the bottom of the lower chamber 1 and communicating with the lower chamber 1, and a sump 2 arranged at the open end of the lower chamber 1 and connected to the lower chamber 1 through a connecting structure. The upper well chamber 3 , a plurality of cover plates 4 that can be covered on the top of the upper well chamber 3 , and the well ring 5 installed on the cover plate 4 . The lower well chamber 1 and the upper well chamber 3 are all set as square wells, and the cover plate 4 is provided with a manhole at the position corresponding to the well ring 5, so that the staff can enter the municipal well for installation, maintenance and other work.

[0048] The lower well chamber 1, the up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap