Rope ladder for metal roof board mounting and metal roof board mounting method

A metal house and installation technology, applied in the direction of roofing, roof covering, roof engineering tools, etc., can solve the problems of low connection reliability, achieve the effects of easy portability and transportation, improve installation quality, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

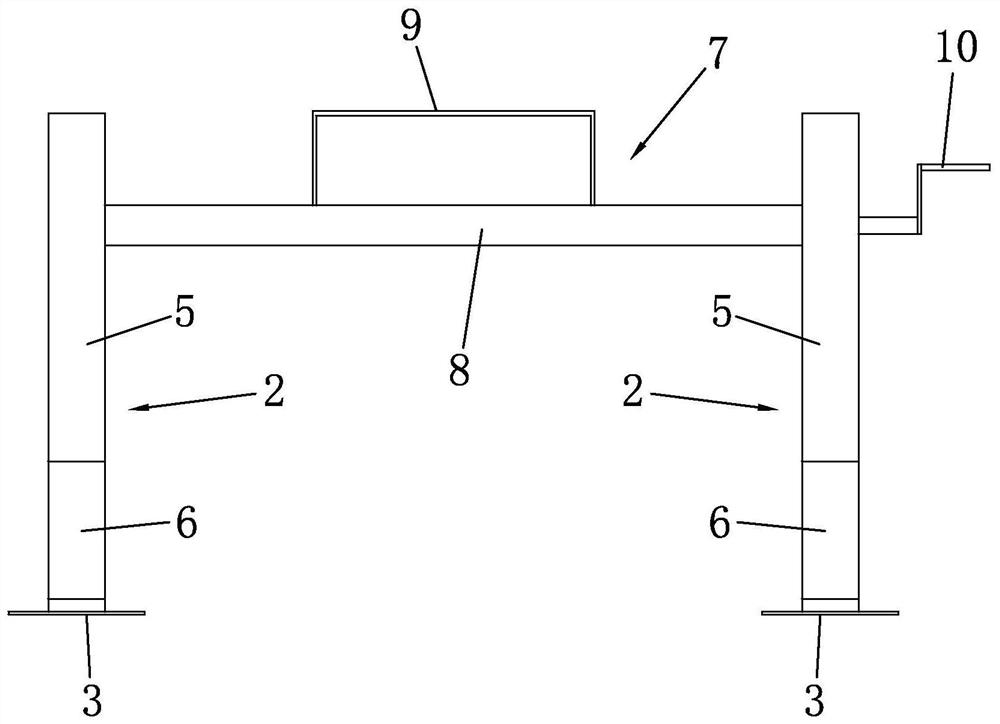

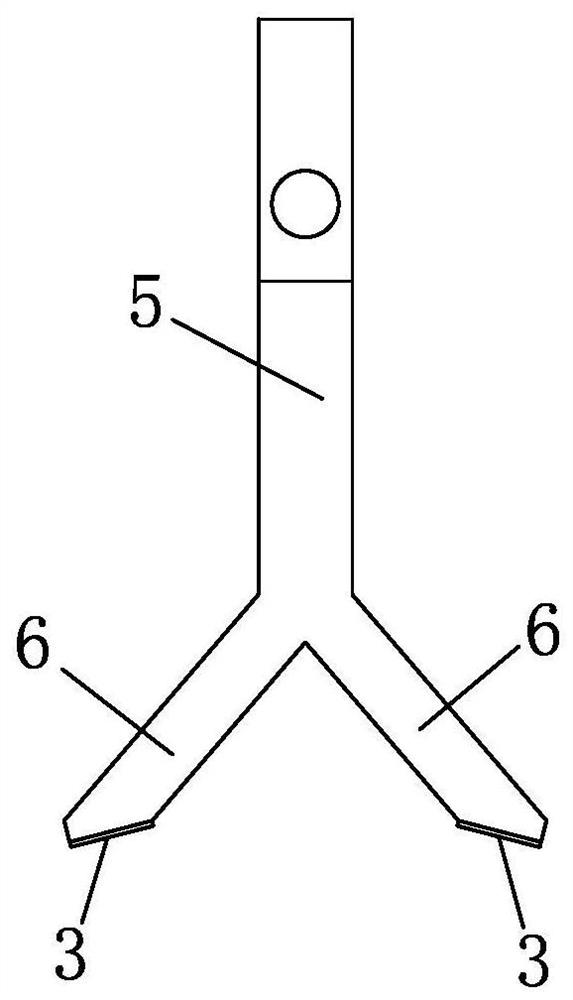

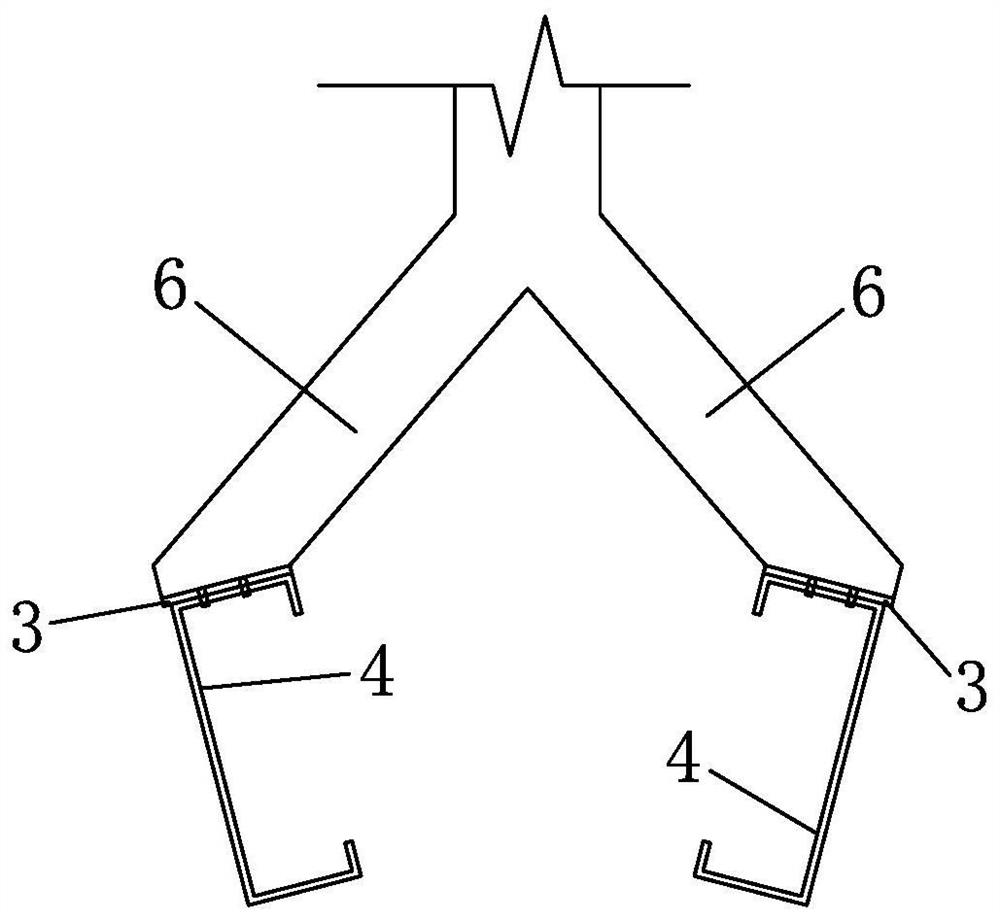

[0065] Such as Figure 1 to Figure 6 As shown, it is Embodiment 1 of the present invention,

[0066] A ladder for installing metal roof panels includes a ladder structure 1, a fixed bracket 2 and a purlin connecting plate 3, and the ladder structure 1 is used as a structure for the superior to install a metal roof panel 16. The ladder structure 1 is arranged on a fixed support 2, and the fixed support 2 is a support of a rigid structure as a load-bearing member of the ladder structure 1. The purlin connecting plate 3 is arranged on the fixing bracket 2, and the purlin connecting plate 3 is fixedly connected with the purlin 4 by self-tapping screws, and the purlin connecting plate 3 is used to increase the contact area between the fixing bracket 2 and the purlin 4. The present invention cancels the installation of the ladder directly on the purlin 4 at the top of the building structure, but fixes the ladder structure 1 on the fixed bracket 2, and the fixed bracket 2 is a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com