Finned heat exchanger

A fin-type heat exchanger and a casing technology are applied in the field of fin-type heat exchangers, which can solve the problems of small heat exchange area and low heat exchange efficiency of fin-type heat exchangers, and achieve a large heat exchange area, High heat exchange efficiency and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

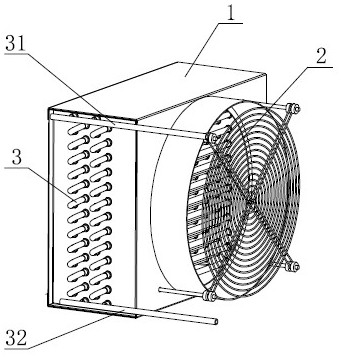

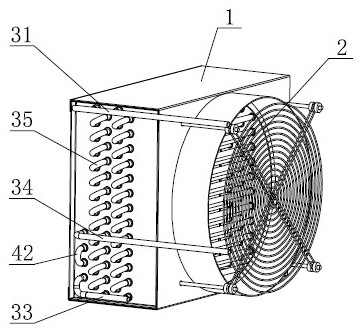

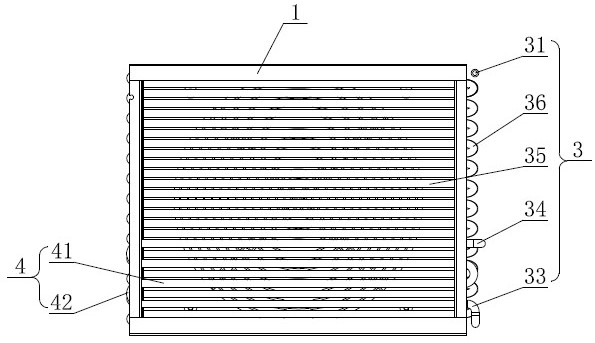

[0029] Such as figure 2 As shown, the front and rear sides of the square casing 1 of the present invention are open surfaces, the left and right sides and the upper and lower sides are closed surfaces, the front open surface of the casing 1 is an air suction port, and the rear side of the casing 1 is fixedly provided with a suction fan. 2. After the suction fan 2 is turned on, the cold air is sucked in from the front suction port of the casing 1 and discharged from the rear side of the casing 1. Such as figure 2 , Figure 4 , Figure 5 As shown, at least one set of refrigeration tube groups 3 are arranged inside the casing 1 from front to back. In this embodiment, two groups of refrigeration tube groups 3 are arranged in the casing 1 from front to back; A refrigerant inlet pipe 31 is provided at the upper end of the right side, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com