A shell and tube heat exchanger, a heat exchanger group and a heat pump unit

A shell-and-tube heat exchanger and heat exchanger technology, which is applied in the field of heat exchange, can solve the problems of insufficient energy supply of heat pump, influence heat transfer coefficient, excess energy supply, etc., so as to increase the total heat transfer area and improve the heat transfer coefficient. , to avoid the effect of easy scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

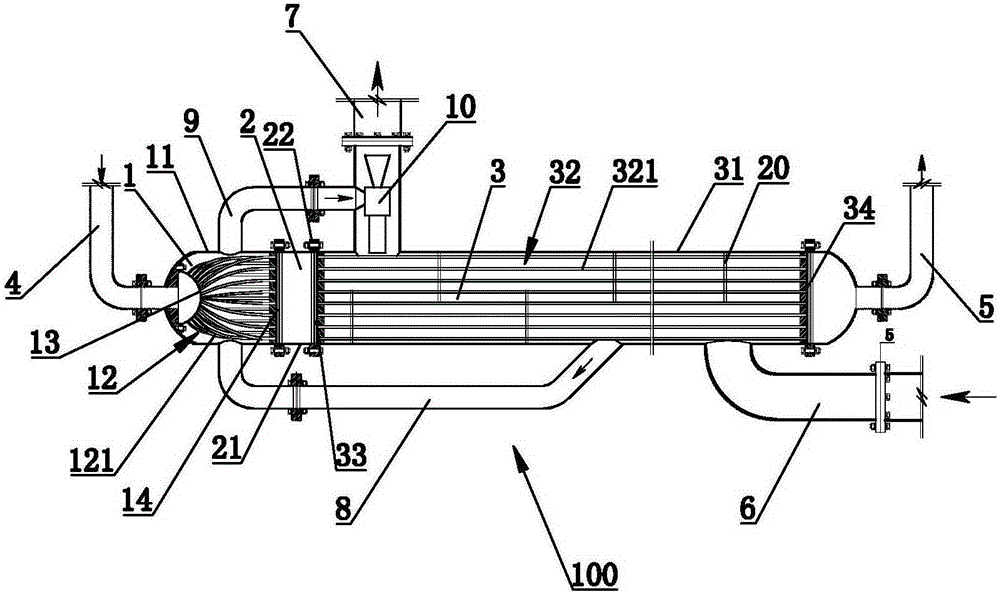

[0031] figure 1 It is a structural schematic diagram of the shell-and-tube heat exchanger in the present invention.

[0032] Refer to attached figure 1 , a shell-and-tube heat exchanger 100, including a secondary heat exchange compartment 1, a buffer compartment 2 and a main heat exchange compartment 3 connected in sequence.

[0033] Wherein, the main heat exchange chamber 3 includes shell tubes 31 and main heat exchange tube bundles 32 arranged in the shell tubes 31, the main heat exchange tube bundles 32 include several main heat exchange tubes 321, and one end of the main heat exchange tube bundles 32 passes through The first main heat exchange tube plate 33 communicates with the buffer compartment 2, the other end of the main heat exchange tube bundle 32 communicates with the refrigerant row pipe 5 through the second main heat exchange tube plate 34, and the diameter of the shell tube 31 is 200mm to 400mm. The diameter of the main heat exchange tube 321 is 7 mm to 11 mm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com