Sensitive element, sensor and vibration monitoring device

A technology of sensitive components and installation parts, applied to measurement devices, vibration measurement in solids, measurement of vibration and other directions, can solve the problems of discount of core parameters of breeze vibration monitoring products, difficult installation process, and not enough attention, etc. Improve the displacement range and frequency range, reduce the difficulty of installation process, and reduce the effect of mechanical performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

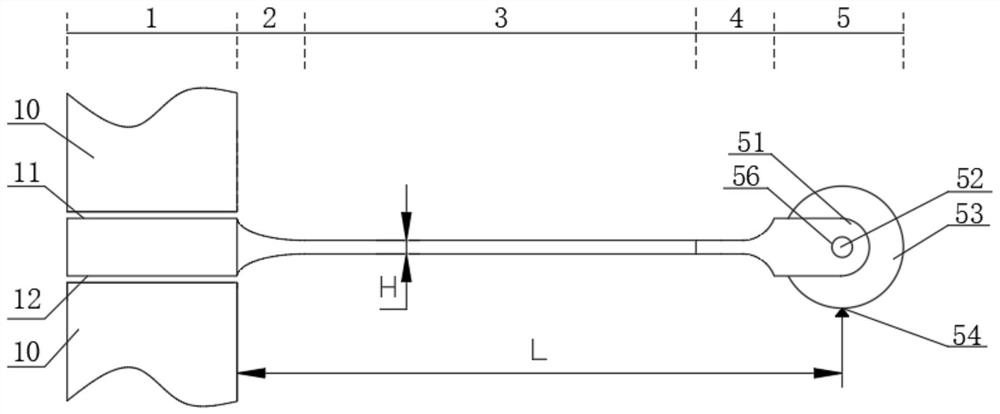

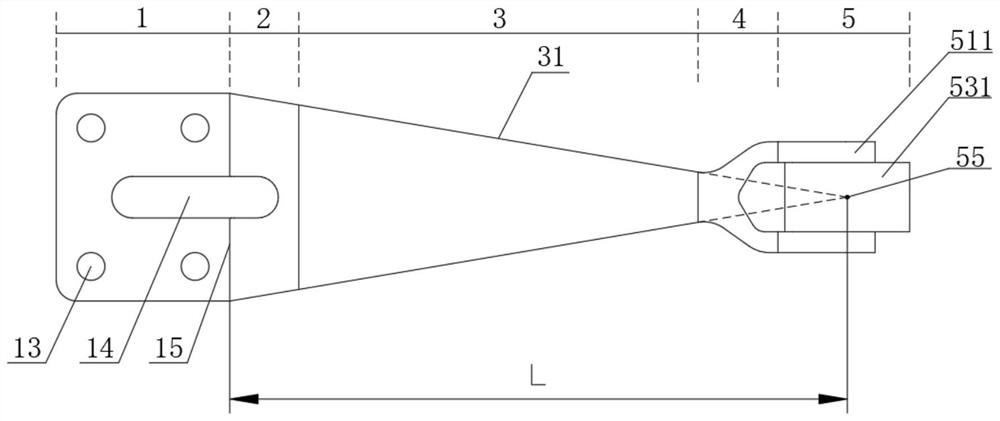

[0049] Such as figure 1 with figure 2 As shown, the present invention provides a sensitive element, which can be used on devices such as vibration sensors. The sensitive element includes a mounting part 1, an elastic deformation part 3 and a contact part 5 connected in sequence, and the mounting part 1 is used for connecting with the monitoring device. Other external devices 10 are connected, and the external devices 10 are connected with the wires and other parts of the monitoring device, so as to fix the position of the sensitive element relative to the wires to be tested and other parts of the monitoring device. The elastic deformation part 3 is the core part of the sensitive element, and it is also the main deformation (strain) concentration area of the sensitive element, and it is also the measurement area. No matter whether the strain gauge or the fiber grating is used as the conversion element, it is arranged in this area. The contact part 5 is in direct contact wit...

Embodiment 2

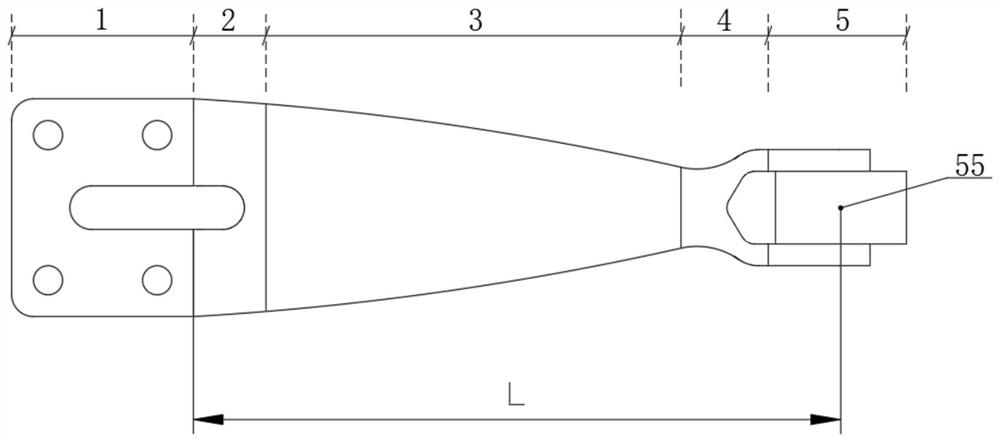

[0053] Such as Image 6 , Figure 7 with Figure 8 As shown, the present embodiment provides a sensitive element, which includes an upper pressing plate 101, a lower pressing plate 102, and a sheet elastic body 103; The point part 5 and the elastic deformation part 3 are located between the mounting part 1 and the contact part 5; the main part of the sheet elastic body 103 can be designed and manufactured using ready-made plates, and the thickness of some parts can be kept consistent, and the structure is simple And the processing process is relatively easy, especially when using high-strength and high-elastic materials for production, this processing performance advantage is more obvious. On the other hand, except that the main part of the sheet-shaped elastic body 103 is made of high-elasticity and high-strength materials, other components can be made of conventional materials, reducing material and processing costs. The elastic deformation part 3 of the sheet-shaped elas...

Embodiment 3

[0057] Such as figure 1 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, this embodiment provides a sensitive element whose structure is basically the same as that of Embodiment 1 and Embodiment 2, the difference is that a first transition section 2 is provided between the installation part 1 and the elastic deformation part 3 ; A second transition section 4 is provided between the elastic deformation part 3 and the contact part 5, and the first transition section 2 and the second transition section 4 are smooth transition areas, respectively allowing the elastic deformation part 3 and the installation part 1 and The transition between the contact parts 5 is smooth, and the first transition section 2 and the second transition section 4 are generally provided with rounded corners, curved surfaces and other gradual changes to achieve a natural transition between different shapes and sections, eliminating stress concentration at the connection.

[0058] Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com