Copper-clad plate batch punching robot

A batch, copper clad laminate technology, applied in metal processing and other directions, can solve the problems of inaccurate moving position, time-consuming and laborious loosening and moving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

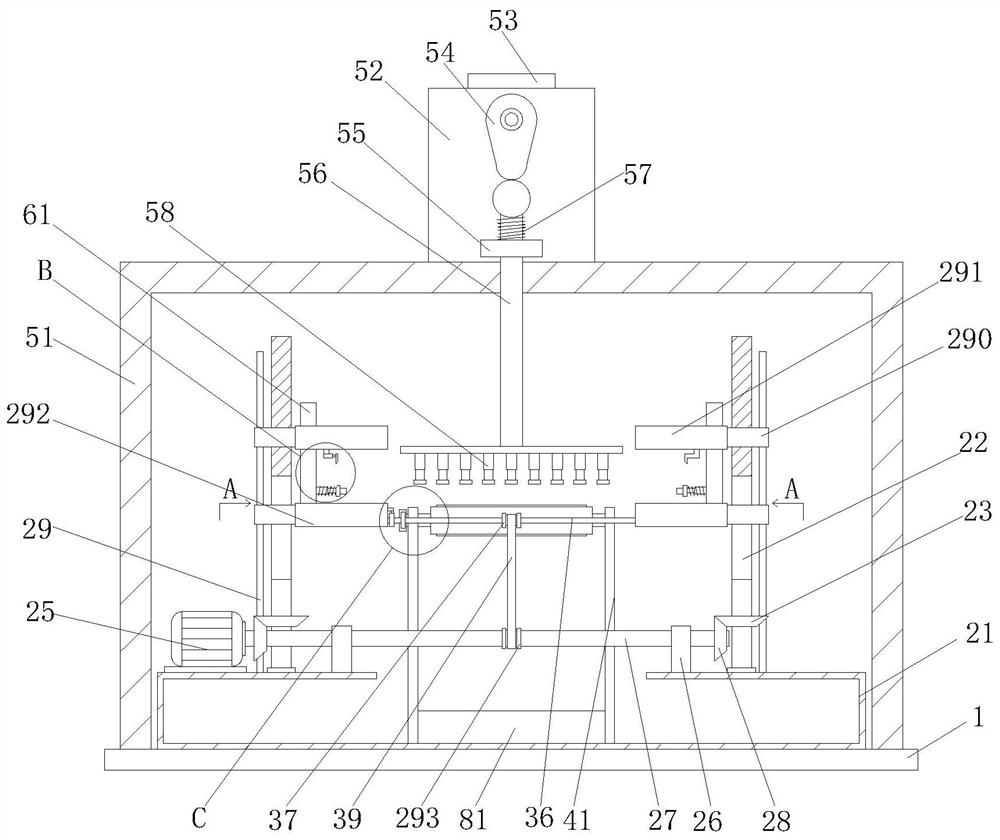

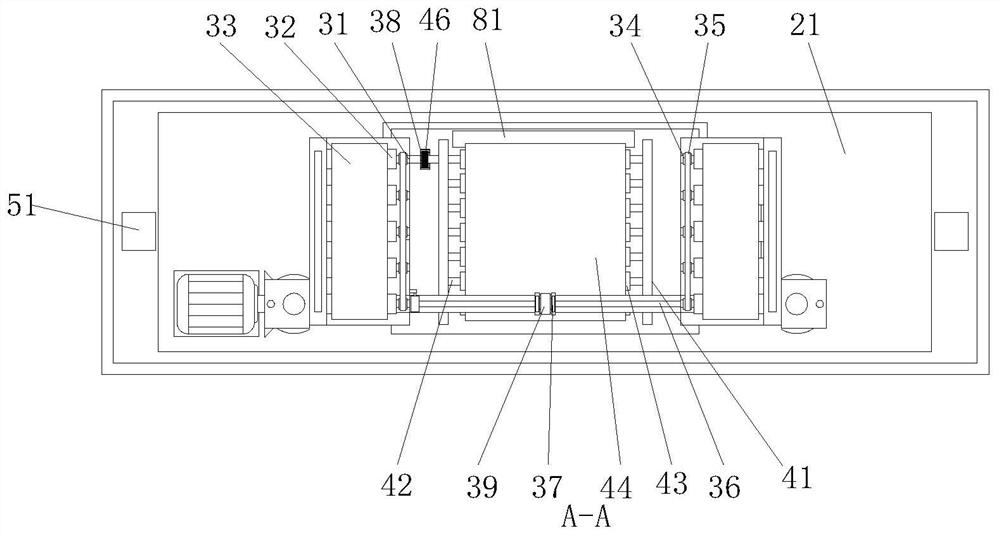

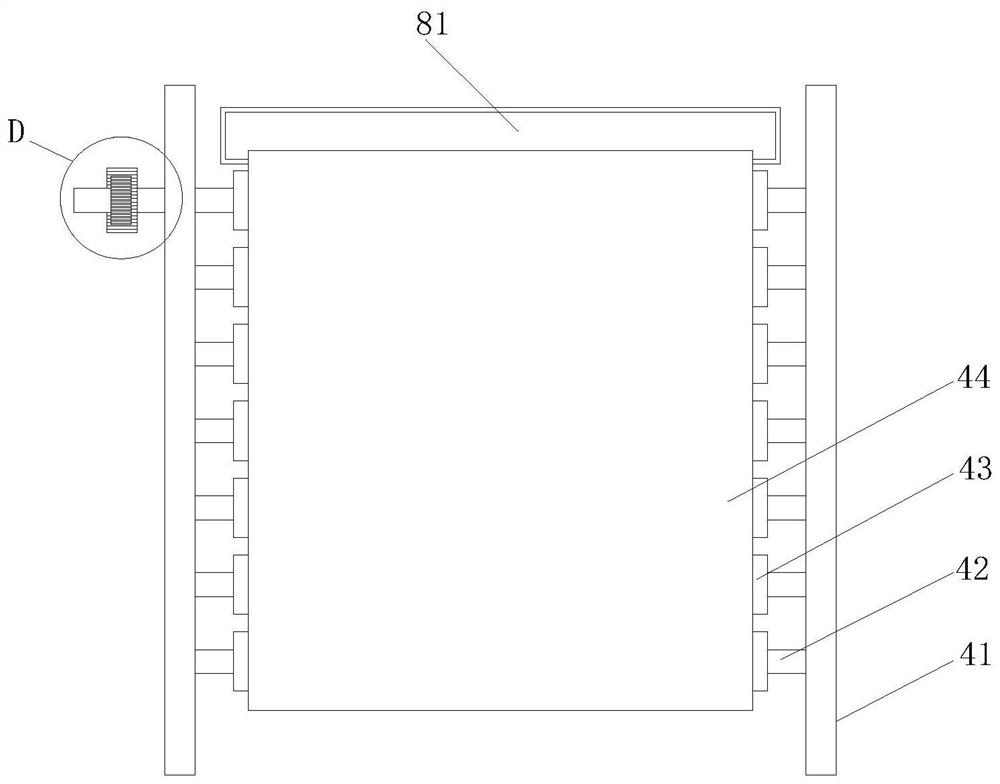

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0027] A batch punching processing robot for copper clad laminates, comprising a base 1, a fixing mechanism, a squeezing mechanism, a conveying mechanism, and a punching mechanism. The feeding mechanism is provided below the fixing mechanism with a conveying mechanism fixedly connected to the base 1; wherein:

[0028] The fixing mechanism includes a rectangular bin 21, a one-way threaded rod 22, a driven bevel gear 23, a driving motor 25, a bearing with seat 26, a first rotating shaft 27, a driving bevel gear 28, a guide rod 29, a connecting block 290, and a fixed top plate 291, the fixed bottom plate 292, the driving pulley 293 and the limit unit 6, the upper surface of the base 1 is fixedly equipped with a rectangular warehouse 21, and both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com