Manufacturing method of explosion-proof panel and explosion-proof panel

A manufacturing method and panel technology, applied to chemical instruments and methods, machine tools suitable for grinding workpiece planes, manufacturing tools, etc., can solve problems such as easy generation of air bubbles on explosion-proof panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as Figure 5-9 As shown, the present invention also provides a method for making an explosion-proof panel, comprising:

[0037] providing an upper pane 12 of a first size;

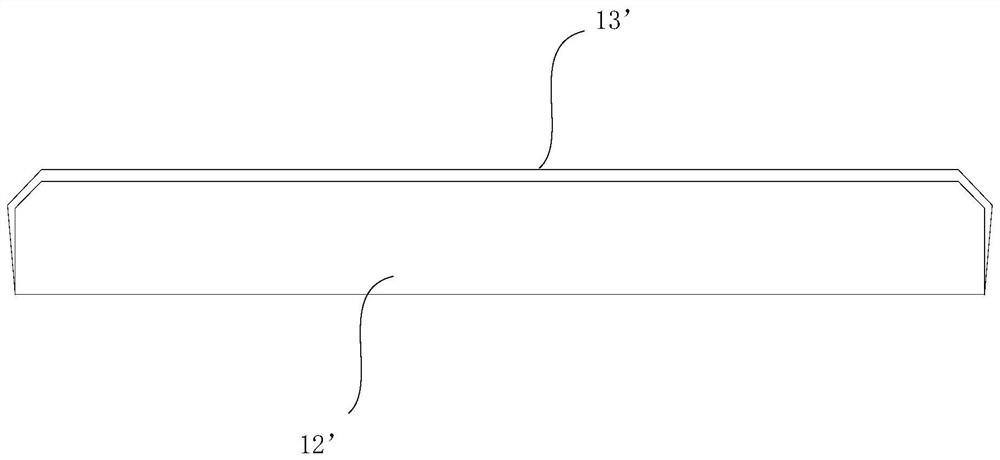

[0038] Coating a film layer 13 on the upper surface of the upper glass 12 of the first size;

[0039] Grinding 0.5-2 mm around the upper layer glass 12 of the first size to become the upper layer glass 12 of the second size;

[0040] providing lower pane 10 of a second size;

[0041] The upper glass 12 of the second size and the lower glass 10 of the second size are bonded together using the PVB film 11 .

[0042] The present invention increases the area of the upper layer glass 12, and then grinds off the redundant part of the upper layer glass 12 to remove the part around the upper layer glass 12 and the lower surface around the coating layer 13, so as to ensure that the PVB film 11 will not stick to the redundant film layer 13 In addition, air bubbles are avoided between the upper glas...

Embodiment 2

[0049] This embodiment also provides an explosion-proof panel, comprising a lower glass 10, a PVB film 11 and an upper glass 12 that are stacked, the upper surface of the upper glass 12 has a film layer 13, and there is no film between the PVB film 11 and the upper glass 12 Layer 13. And there is no film layer 13 around the upper layer of glass 12 and at the chamfer of the upper layer of glass 12 . To prevent the PVB film 11 from being bonded to the upper layer of glass 12, there is a redundant film layer 13 in the middle, so that there are air bubbles in the explosion-proof panel.

[0050] The film layer includes one or more of AG film layer, AR film layer and AF film layer. Among them, the AG film layer is an anti-glare film, which changes the reflective surface of the original glass into a matte surface by chemical etching or spraying, and changes the roughness of the glass surface, thereby making the surface have a matte effect. When the external light is reflected, diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com