Manufacturing method of high-resolution ceramic stained paper

A high-resolution, production method technology, applied in the field of ceramics, can solve the problems of not being able to receive decals, etc., and achieve the effects of easy collection, avoiding clogging, and narrowing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings of the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

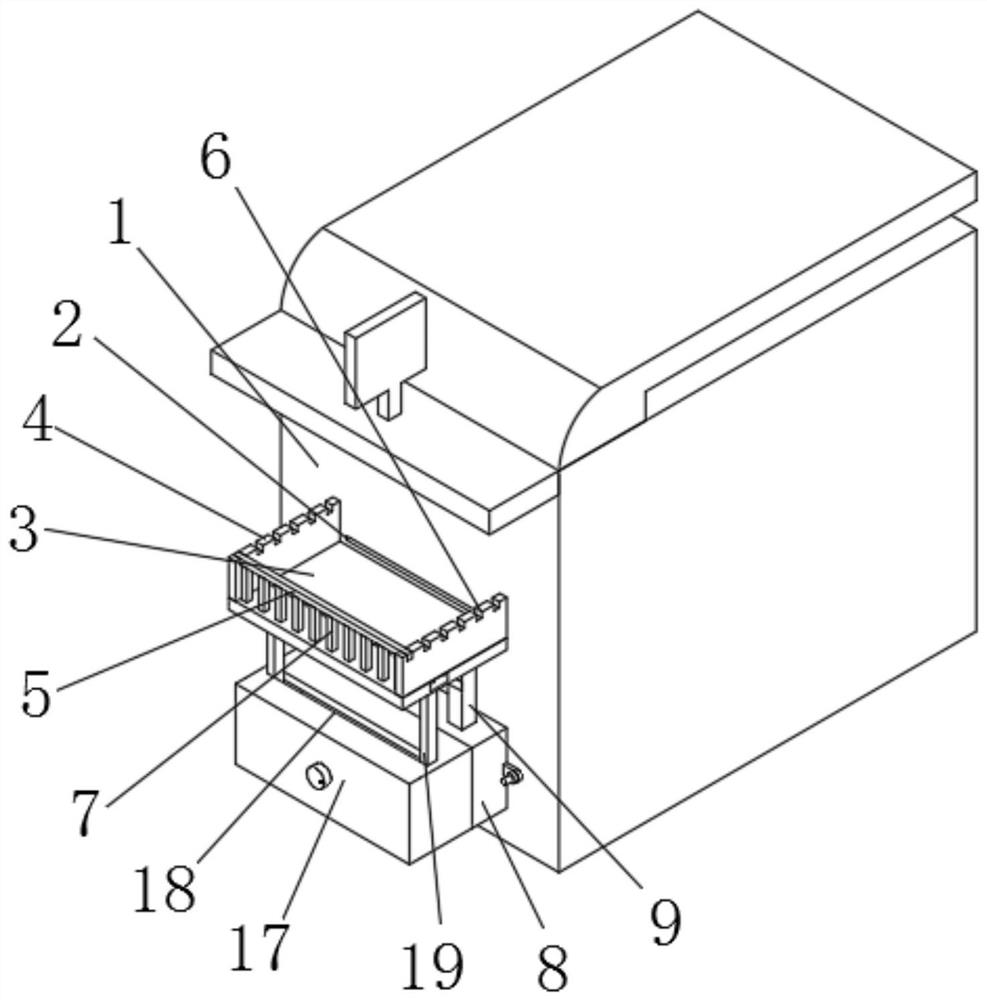

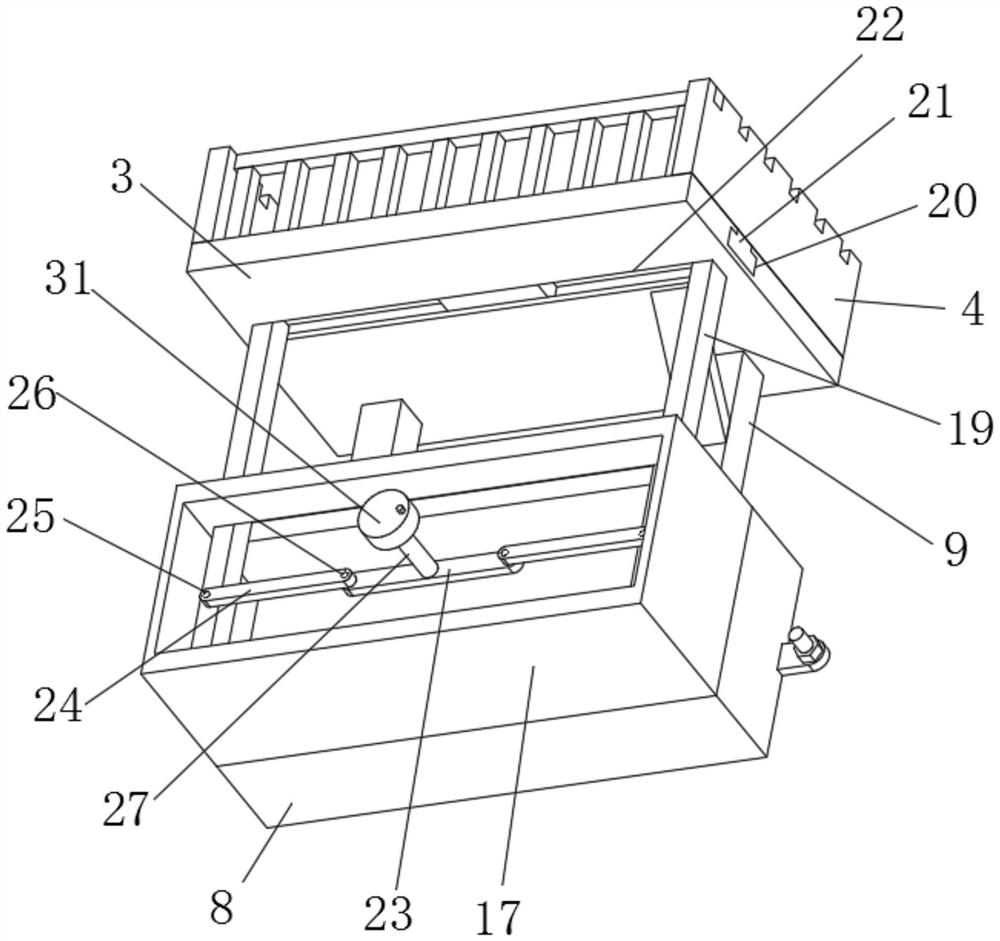

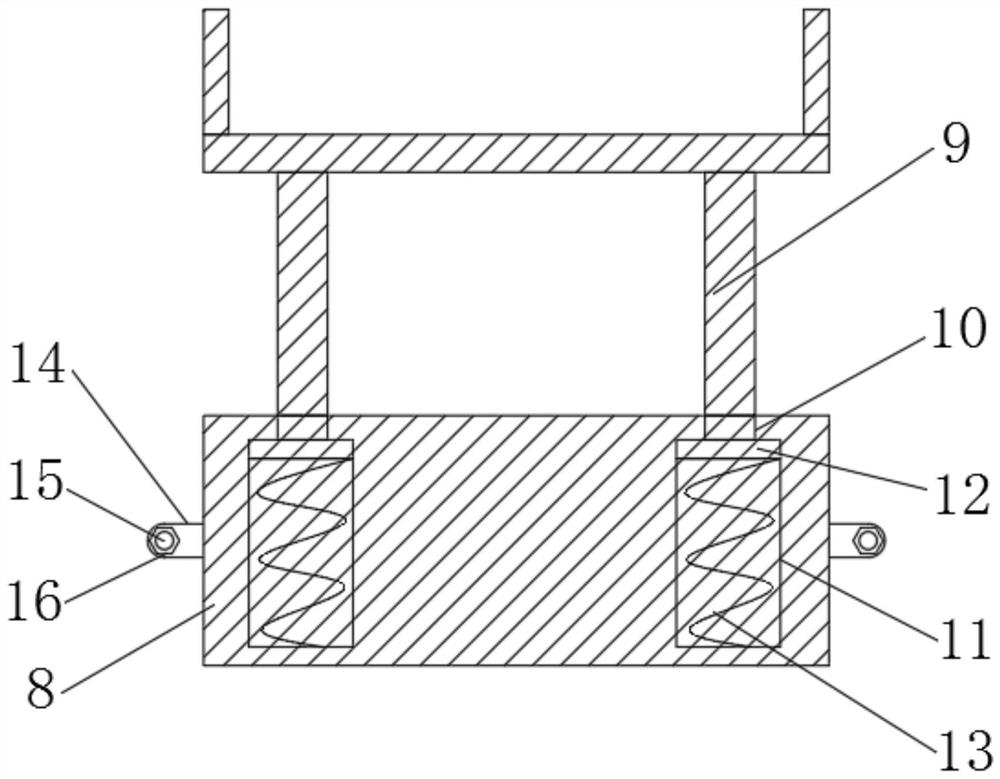

[0033] The manufacture method of the high-resolution ceramic flower paper in the present embodiment adopts figure 1 As shown in the high-resolution ceramic flower paper printer, the printer includes a printer body 1, the printer body 1 is provided with a discharge port 2, and one side of the printer body 1 is movably installed with a carrying box 8 through two mounting ears 14, and the carrying box 8 There are two supporting brackets 9 movable on the top, a cardboa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com