Non-woven fabric feeding and pleating device for mask processing

A non-woven fabric and material feeding technology, applied in clothing, sending objects, thin material processing, etc., can solve the problems of cumbersome processing steps, inability to form folds in masks, etc., and achieve the effect of avoiding the confusion of non-woven fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

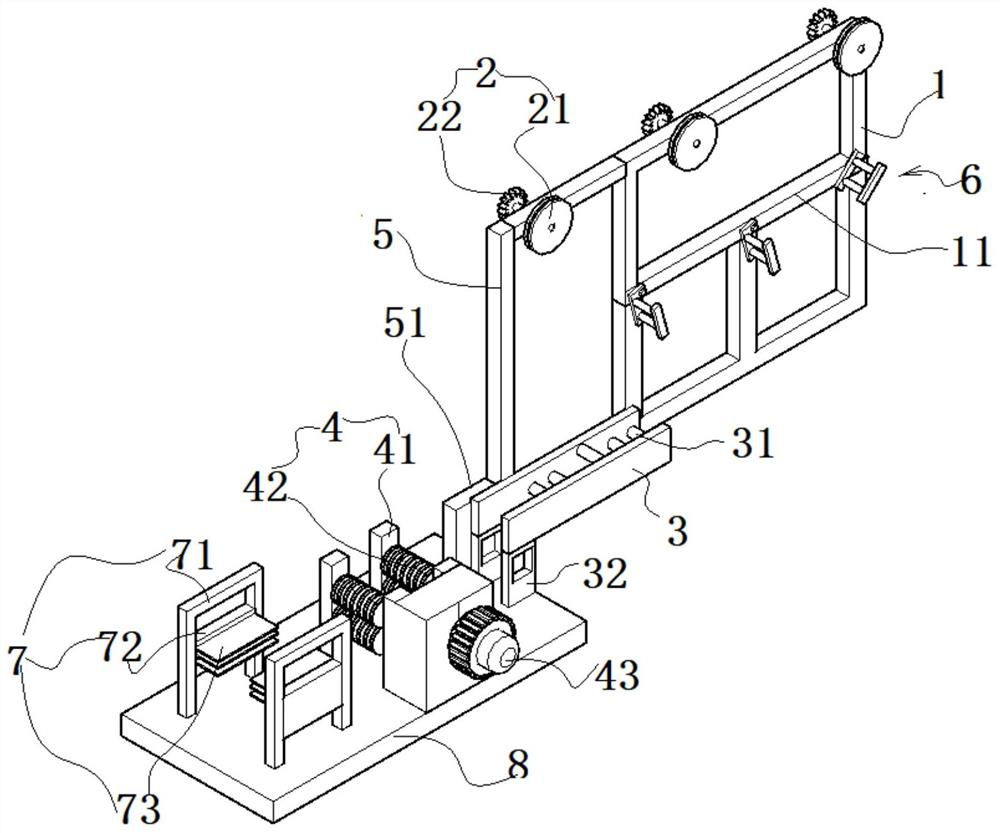

[0044] Such as Figure 1-7 Shown, a kind of mouth mask processing non-woven fabric feeding and crimping device comprises coil material frame 1, and the concrete shape of coil material frame 1 is as follows:

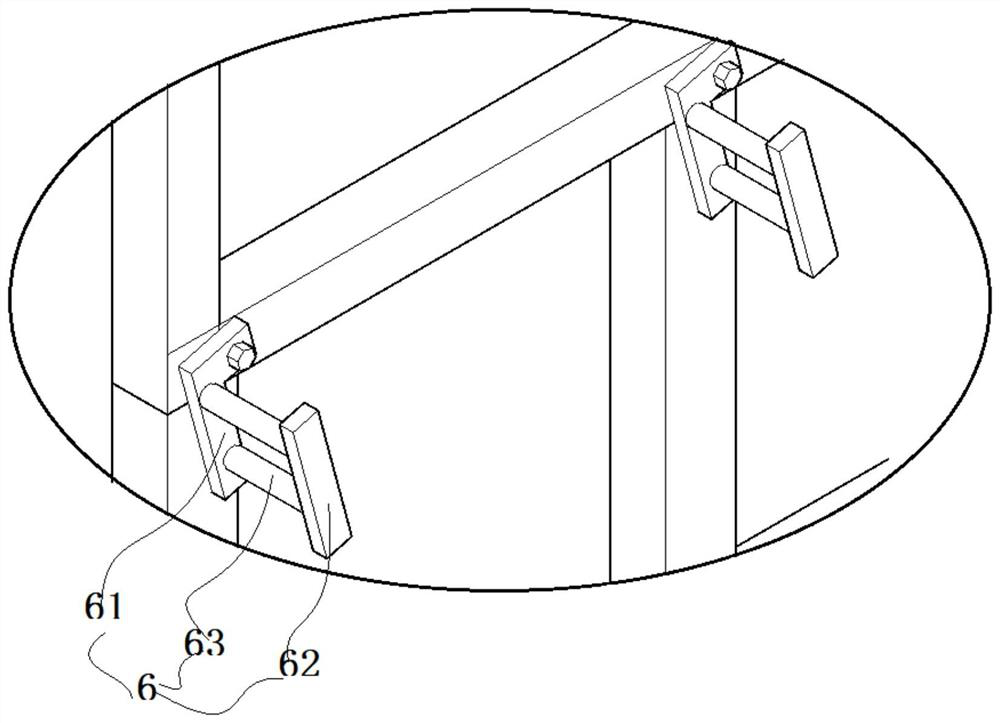

[0045] The coil frame 1 includes a mouth-shaped rod portion 11, the bottom of the mouth-shaped rod portion is fixedly connected with an E-shaped rod portion, and the E-shaped rod portion has three upwardly arranged connecting ends on the mountain, and the connecting ends are fixedly connected to the top of the mouth-shaped rod portion 11 .

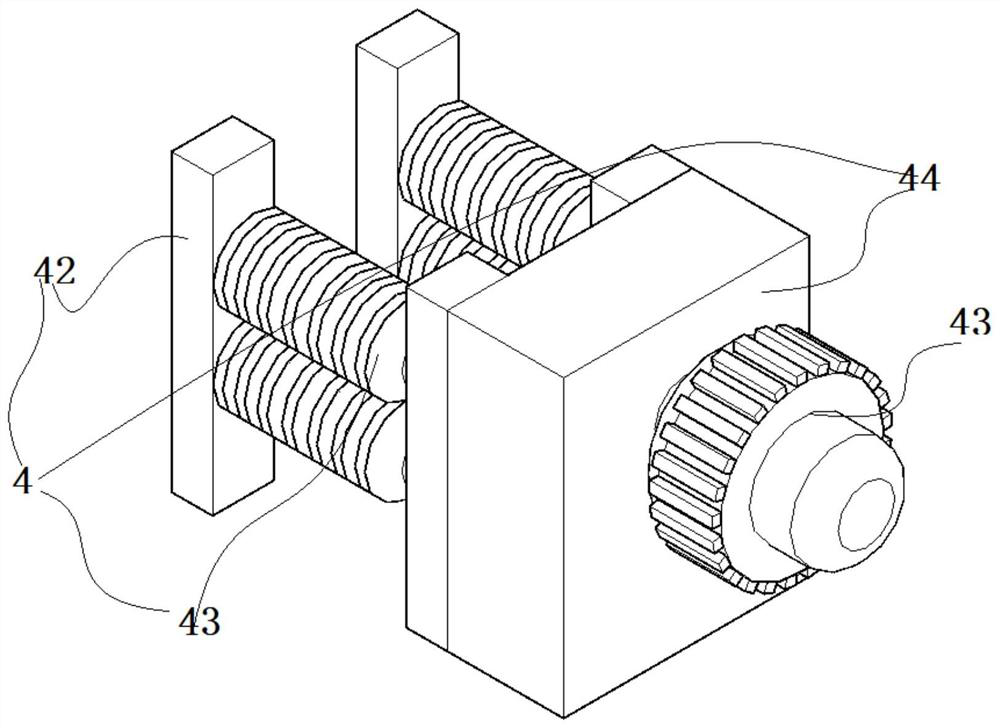

[0046] At the same time, the above-mentioned coil fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com