Film cutting mechanism with slitter edge slitting function

A film cutting and functional technology, applied in the direction of sending objects, thin material handling, transportation and packaging, etc., can solve the problems affecting the production process, and achieve the effect of avoiding accumulation and winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

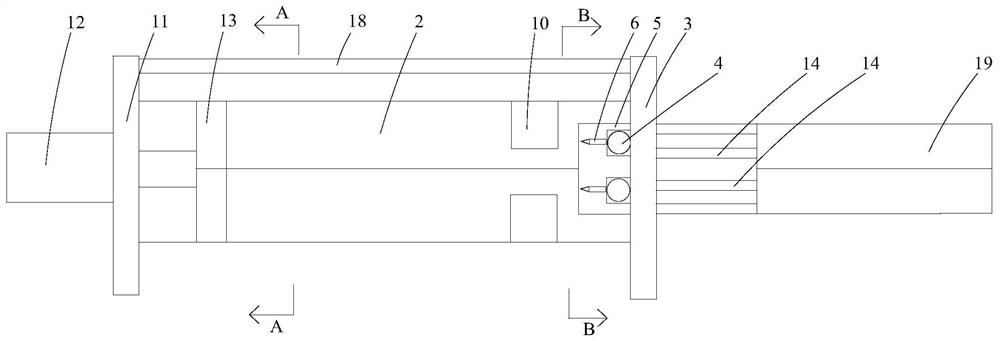

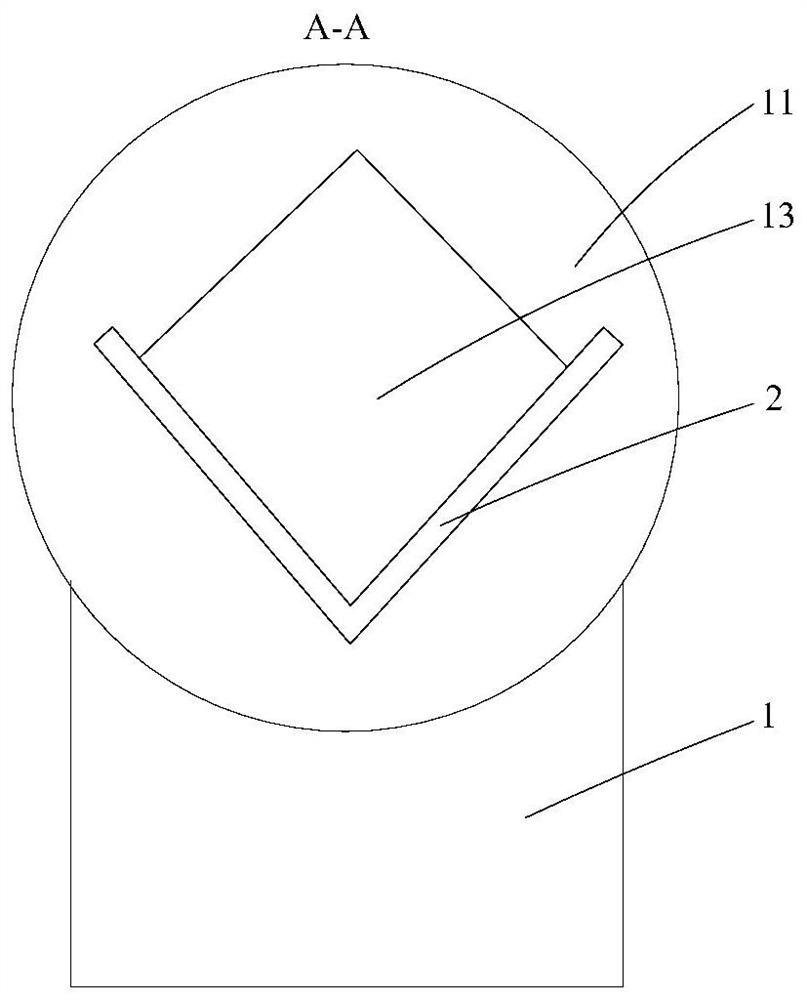

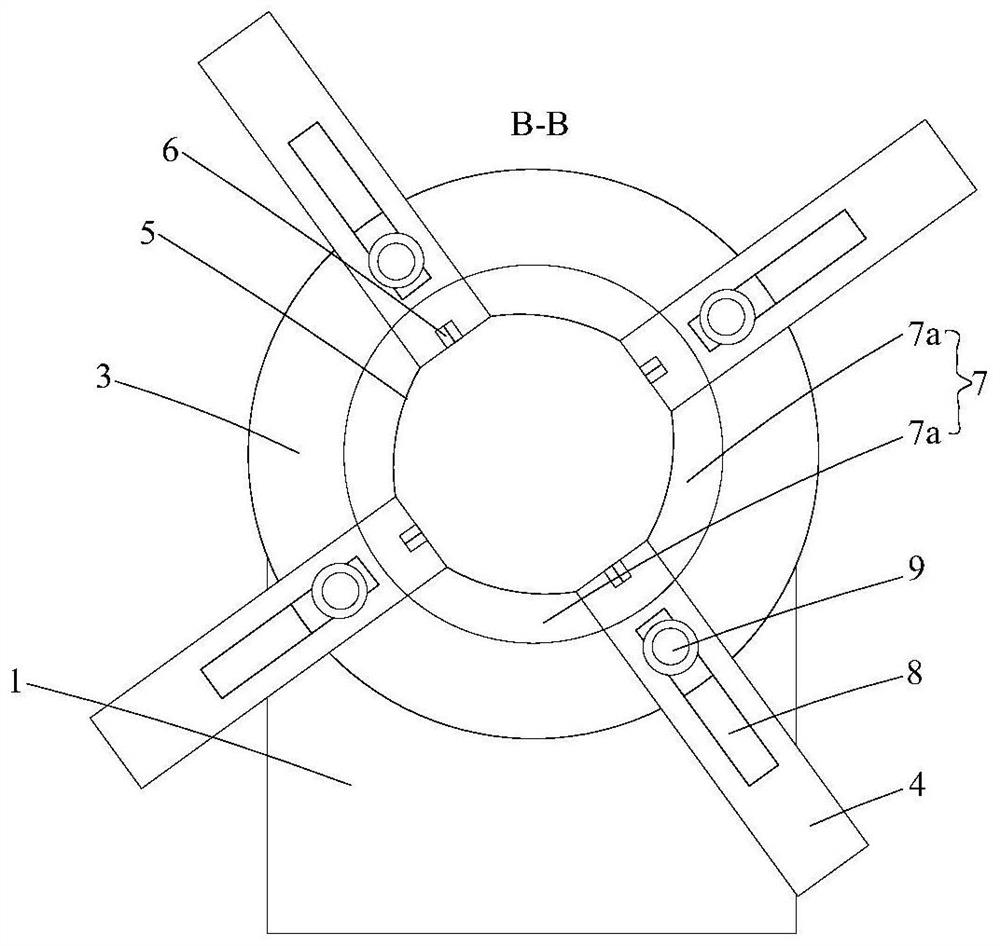

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] The invention relates to the improvement of the film cutting mechanism of the packaging cover film. The improved film cutting mechanism, through the setting of the second cutter, enables the ring-shaped waste edge after ring cutting to be cut into smaller waste edges again, so that it can avoid the blocking of the installation rod and output smoothly. This prevents waste from accumulating and winding around the cutter.

[0029] see Figure 1-4 As shown, a film cutting mechanism with waste edge cutting function is shown, including a frame 1, a bearing groove 2 arranged on the frame 1 for carrying the packaging cover film, and a bearing groove 2 arranged in the longitudinal direction of the bearing groove 2. The film cutting assembly at one end, the push assembly for pushing the packaging cover film towards the film cutting assembly at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com