Multistage cleaning and filtering equipment for domestic sewage

A technology for filtering equipment and domestic sewage, which is applied in the direction of water/sewage multi-stage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of equipment blockage and the inability of sewage to stay for a while, so as to improve the degree of purification , the effect of stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

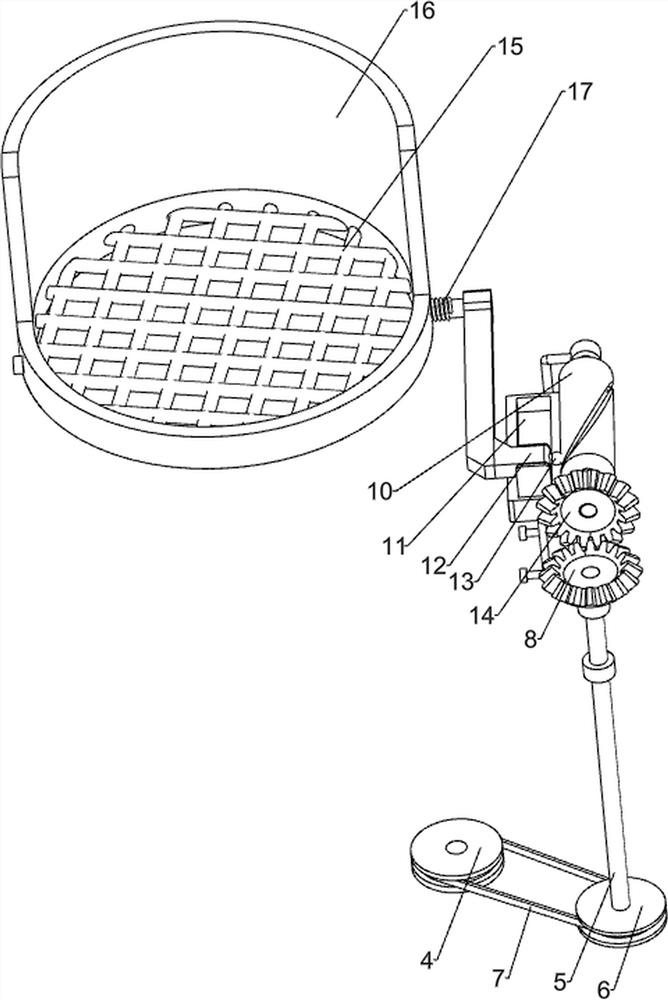

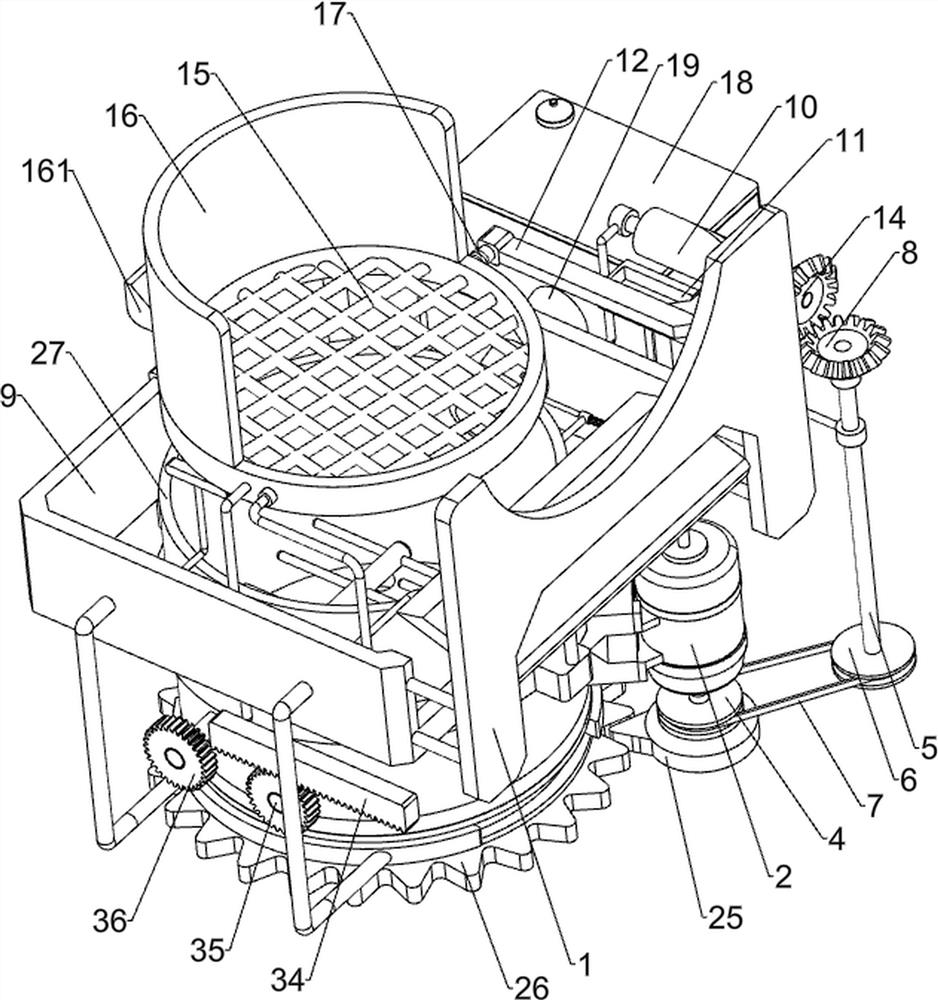

[0022] A multi-stage cleaning and filtering device for domestic sewage, such as Figure 1-Figure 5 As shown, it includes a mounting plate 1, a drive component, a filter component and a cleaning component. The mounting plate 1 is used to install the whole device. Add flocculant to clean the cleaning component, and the right part of the front side of the cleaning component is equipped with a driving component that provides power for work.

[0023] When it is necessary to clean and filter the sewage, start the driving component to work, and then drive the filter component to move to collect and uniformly clean the garbage from the primary filtration of the sewage. At the same time, drive the cleaning component to add an appropriate amount of flocculant to the primary filtered sewage. After the sewage is cleaned, the drive assembly is turned off, so that the filter assembly stops moving, and at the same time, the cleaning assembly stops adding flocculant to the sewage.

[0024] S...

Embodiment 2

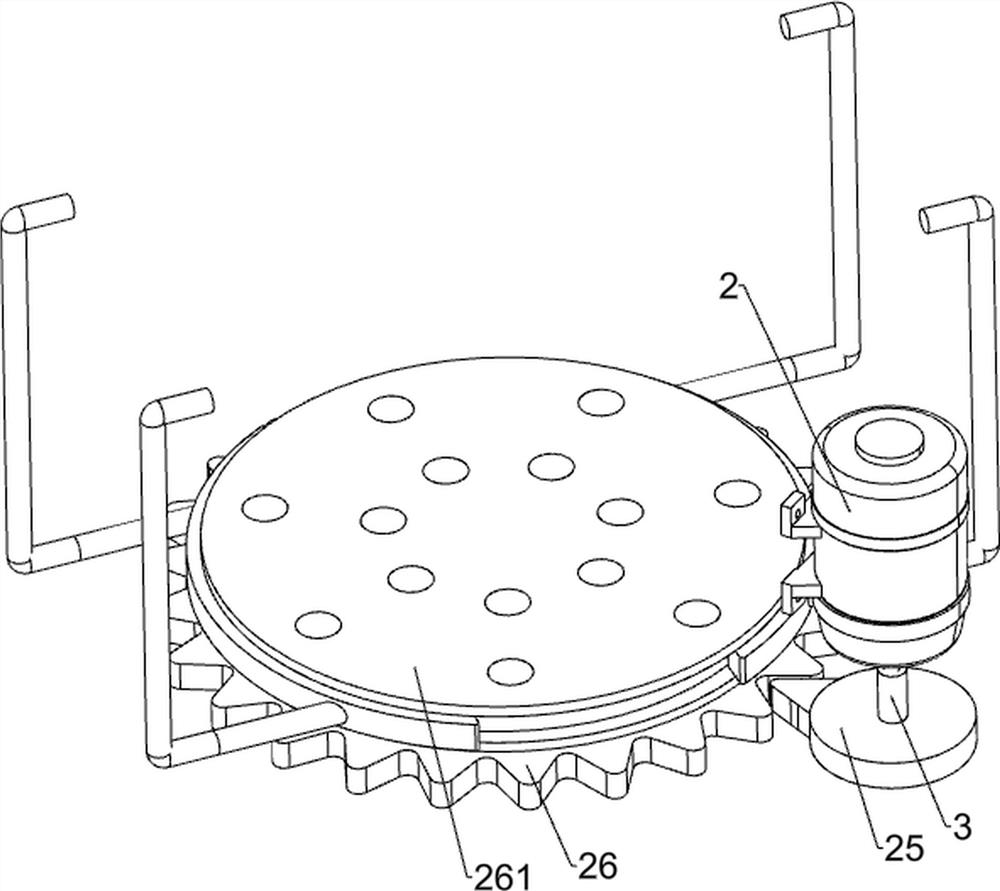

[0031] On the basis of Example 1, such as figure 1 , figure 2 and Figure 6 As shown, it also includes a second L-shaped bar 28, a sliding block 30, a second spring 31 and a swash plate 32, the left side of the filter screen 15 is welded with a second L-shaped bar 28, and the left part of the installation frame 9 is provided with a slide Slot 29, sliding type is provided with sliding block 30 in sliding groove 29, is connected with second spring 31 between sliding block 30 and installation frame body 9, and the right side of sliding block 30 is fixed with swash plate 32 by bolt, and swash plate 32 and The second L-shaped rod 28 fits.

[0032] The rubbish on the filter screen 15 will fall on the swash plate 32, and when the filter screen 15 moves backward, it drives the second L-shaped bar 28 to move backward, and then drives the swash plate 32 to move backward, and drives the sliding block 30 to slide backward , the second spring 31 is compressed, and when the filter scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com