Textile printing and dyeing coating and preparation method thereof

A textile printing and dyeing and coating technology, applied in the field of textile printing and dyeing, can solve the problems of decreased color fastness and inability to adhere, and achieve the effect of improving the bonding force and avoiding falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

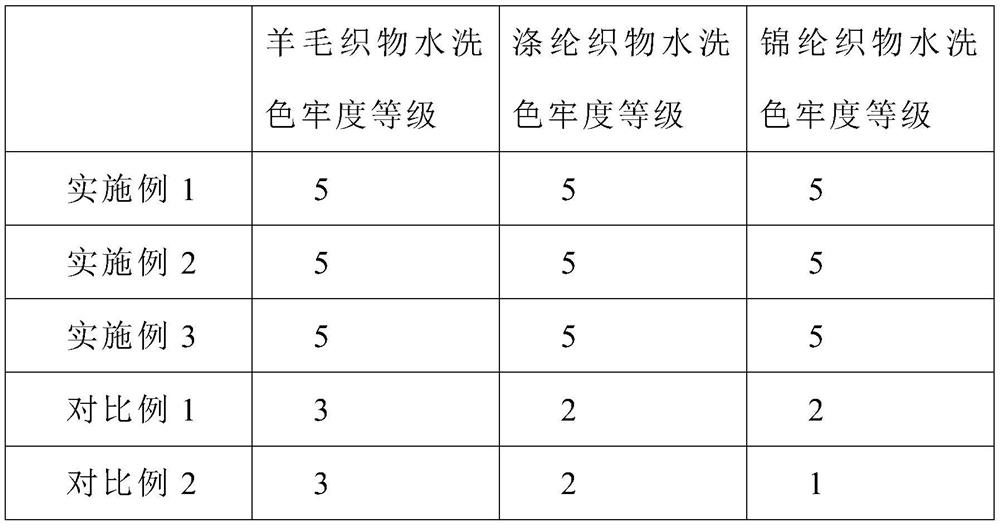

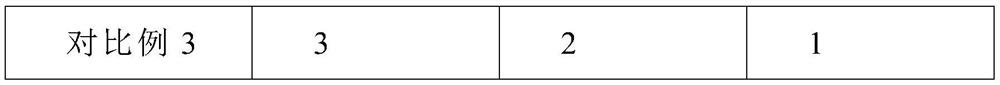

Examples

Embodiment 1

[0033] After mixing the nano-graphene oxide and the sodium polystyrene sulfonate solution with a mass fraction of 3% in a mass ratio of 1:5, at a temperature of 55°C and an ultrasonic frequency of 60kHz, ultrasonic dispersion was performed for 1 hour to obtain a dispersion , and then the resulting dispersion is transported to the spray dryer through a screw pump, under the conditions that the feed rate is 40g / min, the rotation speed of the main plate of the spray dryer is 6000r / min, the inlet air temperature is 120°C, and the outlet air temperature is 70°C Next, spray-dry to form a wrinkled single-layer nano-graphene oxide with a roughness Ra of 5; then the obtained wrinkled single-layer nano-graphene oxide, coupling agent and nano-silica are in a mass ratio of 100:10: 10 Mix and pour into a ball mill jar, and add zirconia ball mill beads according to the mass ratio of the ball to material at 30:1, and ball mill for 48 hours at a speed of 300r / min to obtain a ball mill;

[003...

Embodiment 2

[0038] After mixing nano-graphene oxide and 4% sodium polystyrene sulfonate solution at a mass ratio of 1:8, at a temperature of 58°C and an ultrasonic frequency of 70kHz, ultrasonic dispersion was performed for 2 hours to obtain a dispersion , and then the resulting dispersion is transported to the spray dryer by a screw pump, under the conditions that the feed rate is 60g / min, the rotation speed of the main plate of the spray dryer is 7000r / min, the inlet air temperature is 130°C, and the outlet air temperature is 75°C Next, spray drying to form a wrinkled single-layer nano-graphene oxide with a roughness Ra of 8; then the obtained wrinkled single-layer nano-graphene oxide, coupling agent and nano-silicon dioxide are in a mass ratio of 150:15: 13 Mix and pour into a ball mill jar, and add zirconia ball mill beads according to the mass ratio of the ball to material at 40:1, and ball mill for 56 hours at a speed of 400r / min to obtain a ball mill;

[0039]The following raw mate...

Embodiment 3

[0043] After mixing nano-graphene oxide and sodium polystyrene sulfonate solution with a mass fraction of 5% in a mass ratio of 1:10, at a temperature of 65°C and an ultrasonic frequency of 80kHz, ultrasonic dispersion was performed for 3 hours to obtain a dispersion , and then the resulting dispersion is transported to the spray dryer by a screw pump, under the conditions that the feed rate is 80g / min, the rotation speed of the main plate of the spray dryer is 8000r / min, the inlet air temperature is 140°C, and the outlet air temperature is 80°C Next, spray drying to form a wrinkled single-layer nano-graphene oxide with a roughness Ra of 12; then the obtained wrinkled single-layer nano-graphene oxide, coupling agent and nano-silicon dioxide are in a mass ratio of 200:20: 15 Mix and pour into a ball mill jar, and add zirconia ball mill beads according to the mass ratio of the ball to material at 50:1, and ball mill for 72 hours at a speed of 500r / min to obtain a ball mill;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com