A kind of natural gas compressor skid-belt noise reduction and sound insulation cover and installation method

An installation method and compressor technology, which are applied in the field of compressor noise reduction, can solve the problems of reducing the utilization rate of the station site, physical and mental health damage of daily inspection personnel, and low construction efficiency, so as to improve the utilization rate of the station site and facilitate Control the quality of the project and reduce the effect of concrete pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In view of the existing integrated natural gas compressor noise reduction design that requires a new closed factory building, resulting in a large workload of on-site connection, low construction efficiency, and at the same time, there are problems such as fire protection design, cumbersome land acquisition procedures, high cost, and low utilization rate of the station site. such as figure 1 The floor plan of a natural gas compressor skid-type noise reduction and sound insulation cover is shown in the figure, as shown in the figure. figure 2 Shown is a sectional view of a natural gas compressor pry belt type noise reduction and sound insulation cover. The present invention uses modular assembly of the sound insulation cover wall and the sound insulation cover top, and adopts the sound absorption and insulation panels filled between the keels and the keels. While sound insulation and noise reduction, standardized design, factory mass production, and on-site installation...

Embodiment 2

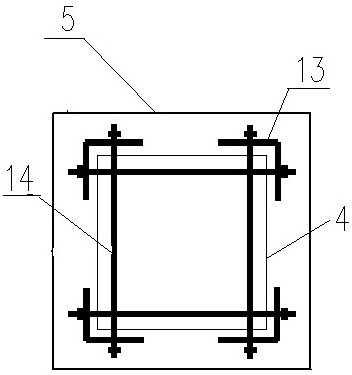

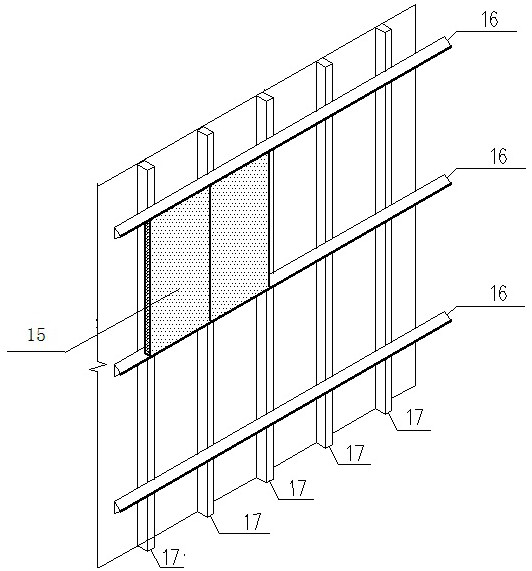

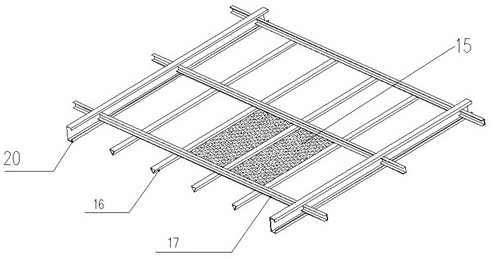

[0041] On the basis of Embodiment 1, in this embodiment, preferably, the sled base perforated steel uprights 4 are arranged vertically to the ground in a square shape, and the cover top purlins 20 are fixedly connected to the top of the sled base perforated steel uprights 4 . The keel is composed of a C-shaped vibration damping cold-formed steel 17 and a triangular keel 16. The C-shaped vibration damping cold-formed steel 17 and the triangular keel 16 are arranged in parallel, and the included angle between the two is 90 degrees. The wall panels of the modularly assembled sound insulation cover wall 8 are connected by sockets and sockets with special-shaped cold-formed thin-walled steel columns 22, and the joints are filled with waterproof sealant 21 and sealed with flashing boards. The modular assembled sound insulation cover wall 8 uses self-tapping screws to connect the keel to the sound absorption and sound insulation filling panel 15 .

[0042] like Figure 4 , Figure ...

Embodiment 3

[0044] On the basis of Embodiment 2, in this embodiment, preferably, the number of electric fans 6 with their own mufflers is set on the top 9 of the sound insulation cover ≥ 2.

[0045] In the present invention, an electric fan 6 with its own muffler is arranged on the top 9 of the sound insulation cover, so as to ensure that the leaked natural gas can be effectively discharged in an accident state, and to ensure that the room of the sound insulation cover always maintains negative pressure operation to ensure the air intake of the compressor. 6 Quantity ≥ 2, designed for redundancy to ensure normal work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com