Sealing structure of valve and electric control throttle valve with same

A technology of sealing structure and sealing ring, applied in valve details, valve operation/release device, valve lift, etc., can solve the problems of poor sealing effect, sealing failure, large change of compression force with size, etc., and achieve elastic modulus The effect of small change, guaranteed reliability, and small fluctuation of force value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

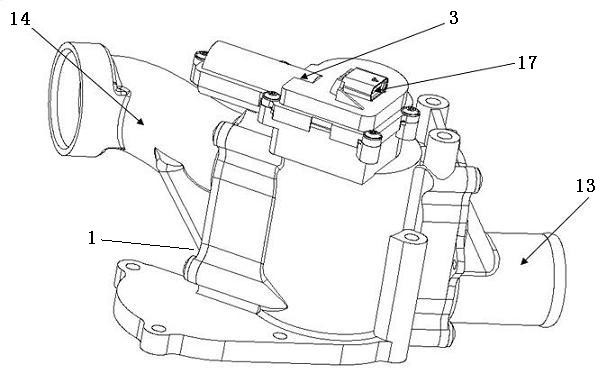

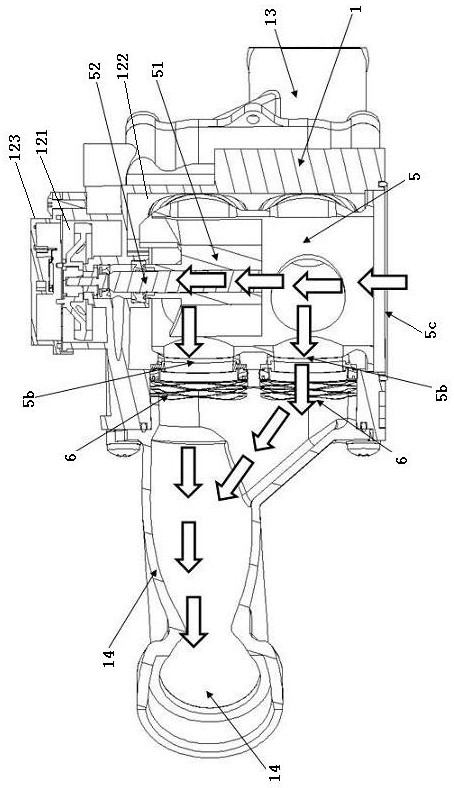

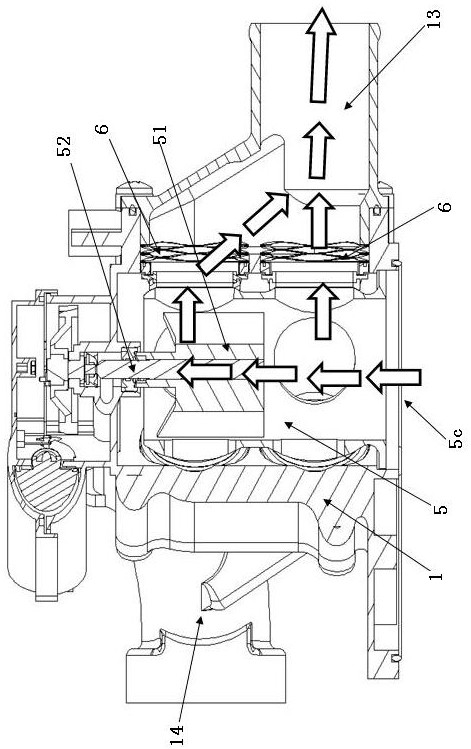

[0024] see Figure 1 to Figure 8 . An electronically controlled throttle valve according to an embodiment of the present invention includes a valve body 1 , a control transmission mechanism 2 , a motor 3 , a spool position sensor 4 and a spool 5 .

[0025] The valve body 1 includes a valve body body 12 , a large circulation joint 13 and a small circulation joint 14 . The large circulation joint 13 and the small circulation joint 14 are respectively connected to the side of the valve body body 12 . The valve body 12 is provided with an electrical cavity 121 and a fluid cavity 122. The electrical cavity 121 is used to accommodate the control transmission mechanism 2 and the motor 3. The fluid cavity 122 is used to transport fluid. The electrical cavity 121 and the fluid cavity 122 are separated from each other by a partition . In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com