Reheating regulating valve of subcritical 300 MW steam turbine

A reheat regulating valve and steam turbine technology, which is applied in the field of steam turbines, can solve the problems of poor tightness and poor regulation, and achieve the effects of ensuring effective operation, improving tightness and regulation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

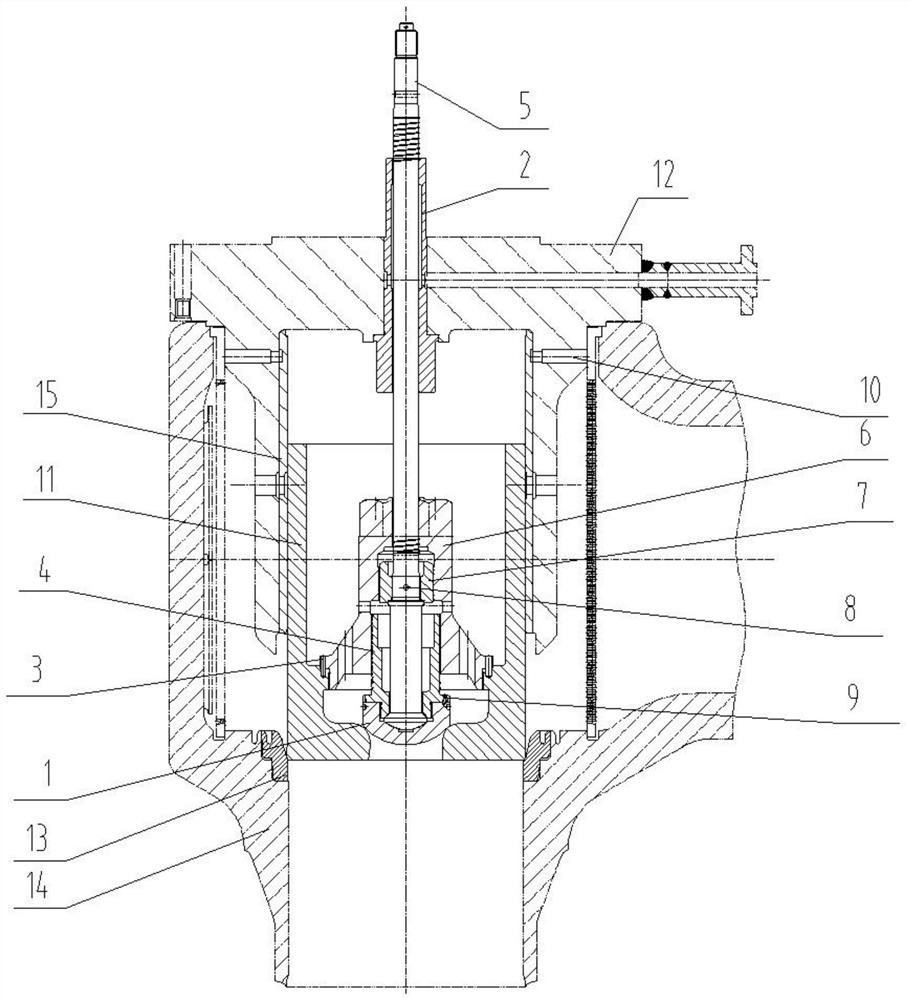

[0008] Specific implementation mode one: combine figure 1 Explain that a subcritical 300MW steam turbine reheat regulating valve described in this embodiment includes a pre-opening valve 1, a lock nut 4, a valve stem 5, a medium pressure regulating valve connecting sleeve 6, a valve disc 11, a valve cover 12, a valve Seat 13, valve body 14 and bushing 15, valve stem 5 are inserted vertically on the end face of valve cover 12, the lower end of valve stem 5 is fixedly connected with pre-opening valve 1, and the upper end of pre-opening valve 1 is fixedly connected with locking valve. The nut 4, the upper end of the lock nut 4 is provided with a connecting nut 7, the lock nut 4 and the connecting nut 7 are all arranged on the outside of the lower end of the valve stem 5, and the upper end of the pre-opening valve 1 is provided with a medium pressure regulating valve connecting sleeve 6, The upper end of the connecting sleeve 6 of the medium pressure regulating valve is set on the...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 Explanation, in this embodiment, the outer peripheral side wall of the lower end of the connecting sleeve 6 of the medium pressure regulating valve described in this embodiment extends outwards with an extension section, and the outer peripheral side wall of the extension section is fixedly connected to the inner side wall of the valve disc 11 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 It should be noted that a plurality of connecting sleeve through holes are evenly distributed along the circumferential direction on the extension section of this embodiment. Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com