Device for testing performance of rotary electric brush of constructional engineering machinery

A technology of rotating brushes and construction engineering, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of low detection efficiency, hidden dangers of toner safety, etc., and achieve the effect of preventing offset and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

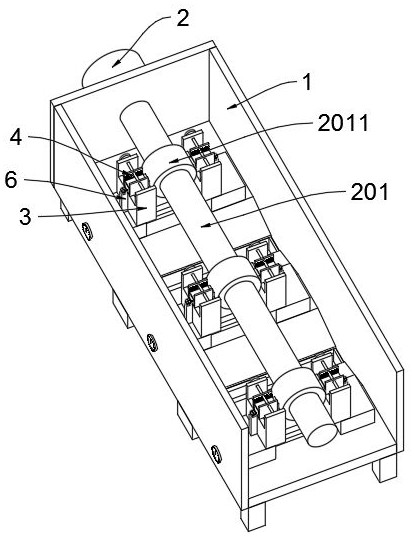

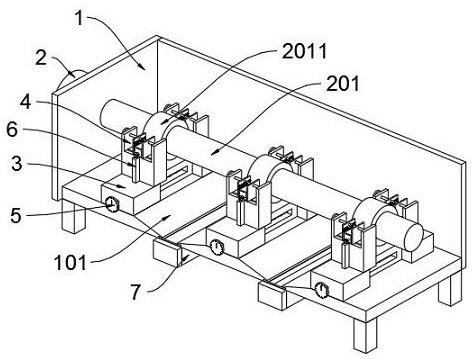

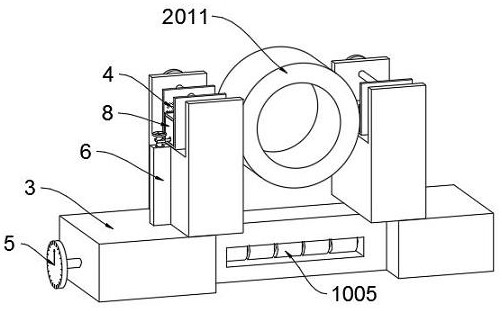

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The present invention provides a performance test device for rotating brushes of construction engineering machinery, which includes a box body 1 and a fixed casing 8; a motor 2 is provided at the left end of the box body 1, and the motor 2 is rotationally connected with a transmission shaft 201, and three shafts are evenly arranged on the transmission shaft 201. A set of commutation pieces 2011; the lower end of the box body 1 is fixedly connected to the bottom plate 101, and two sets of V-shaped grooves are symmetrically opened on the surface of the bottom plate 101, and the bottom of the V-shaped grooves is provided with a collection box 7; the upper end of the bottom plate 101 is aligned with three sets of bases 3. The upper end of the base 3 is symmetrically provided with two sets of limit devices 4, and the limit devices 4 are fixedly connected to the connecting columns 6; the inside of the fixed shell 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com