belt feeder

A belt feeder and feeder technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of easy bending of the carrier tape and the inability to maintain the carrier tape, etc., and achieve the realization of parts cost, ease of precision, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

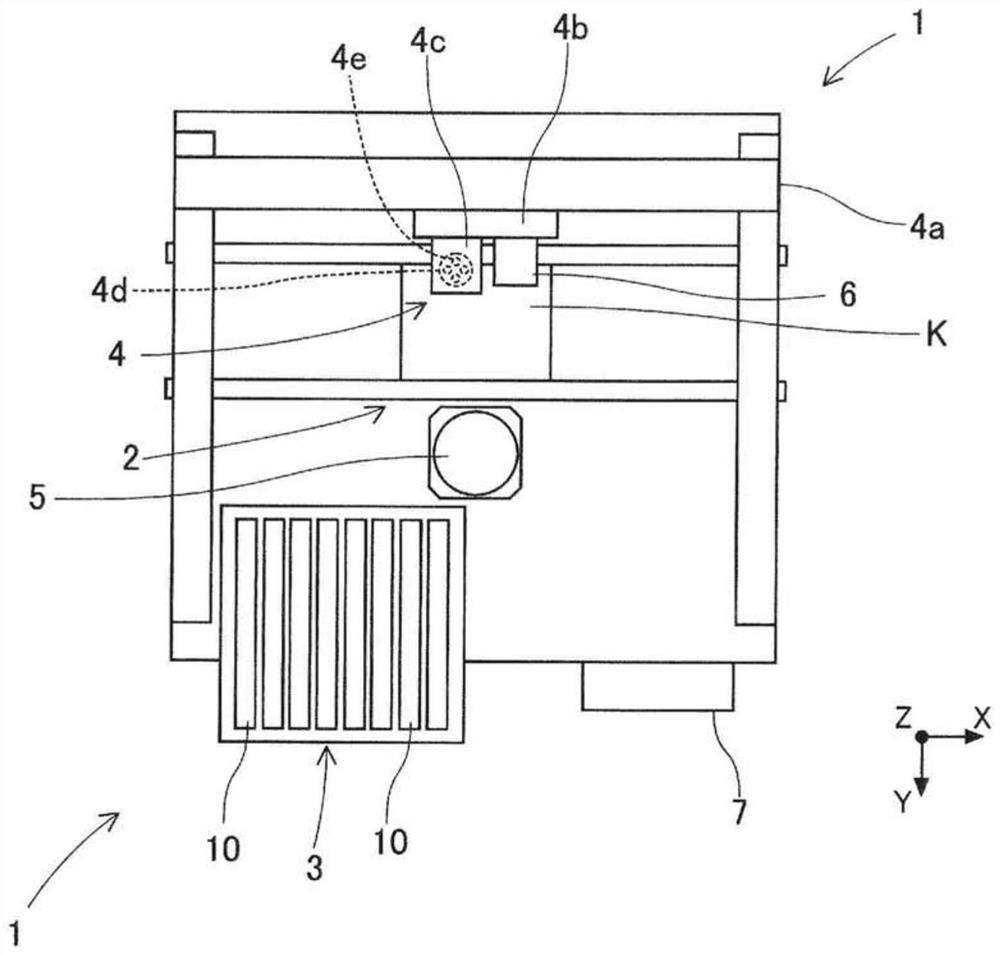

[0027] 1. Outline structure of component mounting machine 1

[0028] Hereinafter, an embodiment to which the tape feeder disclosed in this specification is applied will be described with reference to the drawings. First, refer to figure 1 , the schematic configuration of the component mounting machine 1 using the tape feeder 10 will be described. In addition, in figure 1 In the horizontal width direction of the component mounting machine 1 ( figure 1 left and right direction) as the X direction, the horizontal length direction of the component mounting machine 1 ( figure 1 Up and down direction) is set as the Y direction, and the vertical direction perpendicular to the X direction and the Y direction ( figure 1 The direction vertical to the paper surface) is set as the Z direction.

[0029] Such as figure 1 As shown, the component mounting machine 1 mainly includes a substrate conveying device 2 , a component supply device 3 , a component transfer device 4 , a component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com