Intelligent logistics sorting workbench

A workbench and logistics technology, which is applied in the direction of sorting, conveyor objects, conveyors, etc., can solve the problems of high labor intensity, inconvenience for staff to pick up, and loss of small items by express delivery, so as to reduce the investment of human resources and save distribution. The time of picking, the effect of avoiding loss or forgetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

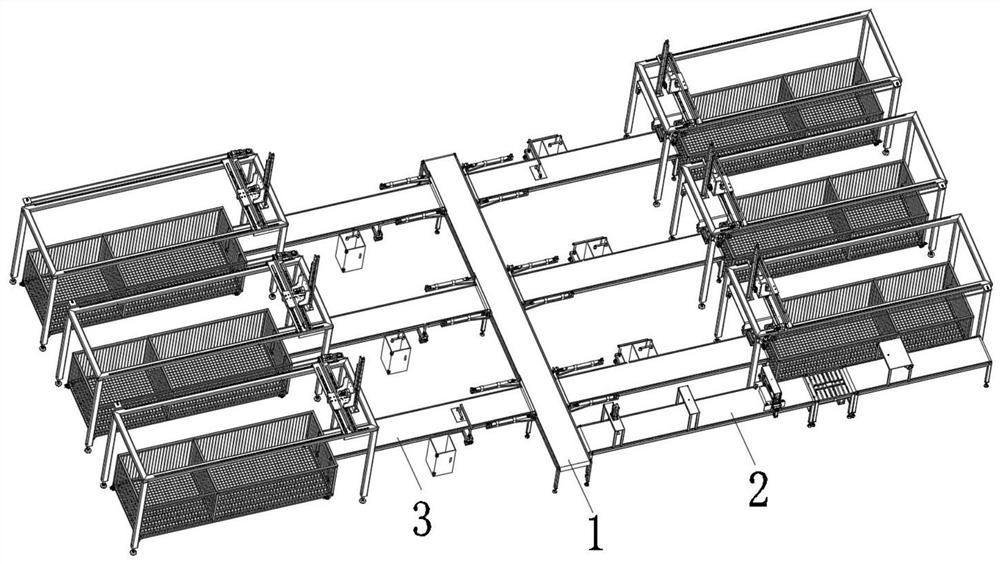

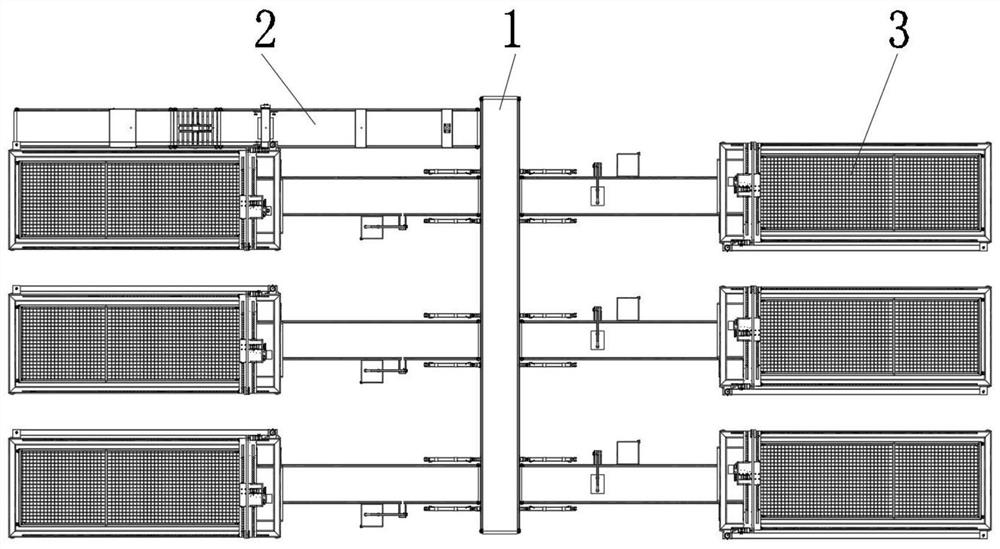

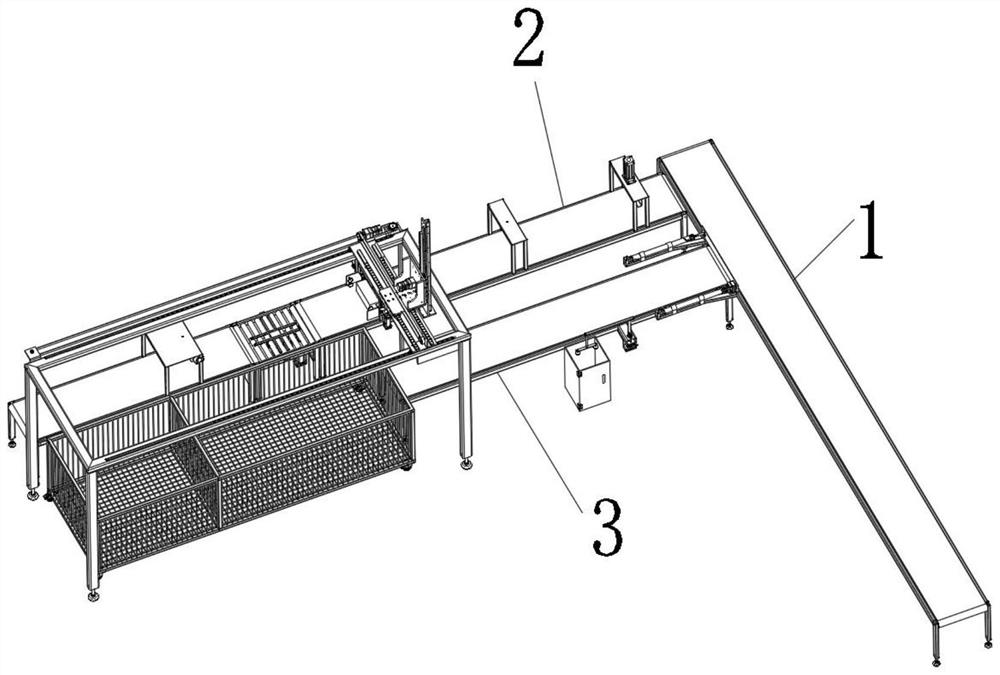

[0054] see Figure 1-18 As shown, a smart logistics sorting workbench includes a transitional conveying line 1, and is characterized in that: one side of the transitional conveying line 1 is provided with a code-scanning and turning-over conveying line 2, and both sides of the scanning and turning-over conveying line 2 are A plurality of sets of sorting devices 3 are symmetrically arranged, and the sorting devices 3 are all located on the back side of the transitional conveying line 1;

[0055] Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com