Digital display feeler gauge for measuring small aperture and working method thereof

A technology of small aperture and feeler gauge, which is applied in the field of measuring tools, can solve the problems that the accuracy can only reach 0.1mm, and it is easy to produce measurement errors, etc., and achieve the effects of easy processing, manufacturing, calibration and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

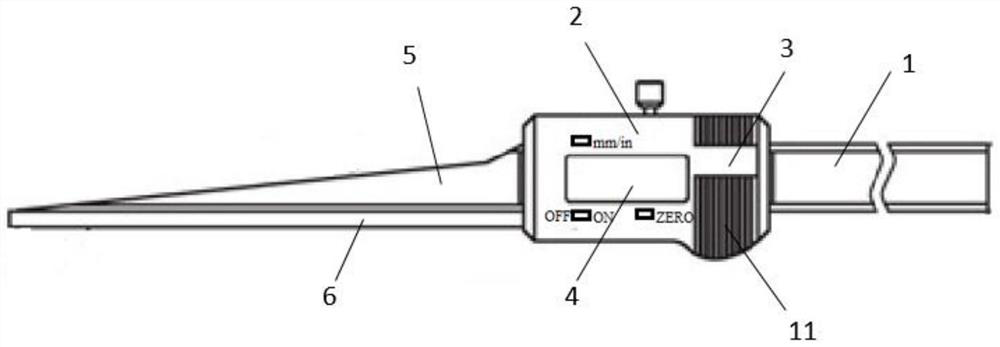

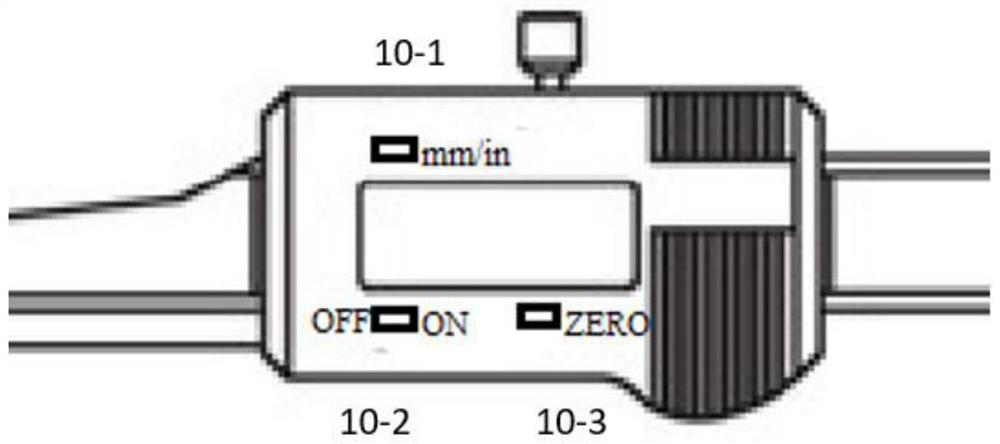

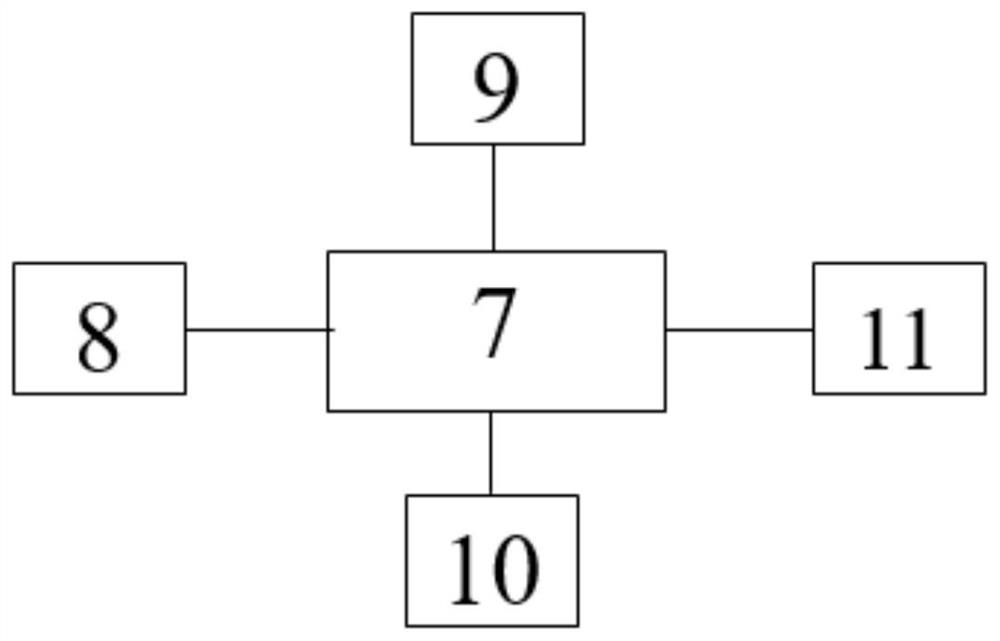

[0033] Such as figure 1 , is a digital display feeler gauge for measuring small apertures of the present invention, including a feeler gauge body, which includes a main ruler 1, a vernier 2, a semi-conical feeler gauge 5 and a positioning block 6; the vernier 2 is slidably installed on the main ruler 1 , one end of the vernier 2 is fixedly connected with the positioning block 6, one end of the main ruler 1 is fixedly connected with the bottom surface of the semi-conical feeler gauge 5, and the vertical section of the semi-conical feeler gauge 5 is closely attached to the side of the positioning block 6; when the main ruler 1 When the vernier 2 is tightened, the apex of the semi-tapered feeler gauge 5 is aligned with the end of the positioning block 6 .

[0034] The ratio of the radius of the bottom surface of the semi-conical feeler gauge 5 to the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com